Automation in Sheet Metal Forming Machines

The manufacturing industry has undergone a significant transformation over the past few decades, largely driven by the integration of automation technologies. Sheet metal forming, a critical process in sectors such as automotive, aerospace, and construction, has seen remarkable advancements through automation. This article explores the various aspects of automation in sheet metal forming machines, highlighting its benefits, key technologies, and future trends.

The Evolution of Sheet Metal Forming

Sheet metal forming involves shaping metal sheets into desired geometries using processes like bending, stamping, deep drawing, and punching. Traditionally, these operations were labor-intensive, requiring skilled operators and involving high risks of errors and accidents. The advent of Computer Numerical Control (CNC) technology in the late 20th century marked the beginning of automation in this field. Today, fully automated systems equipped with robotics, artificial intelligence (AI), and the Internet of Things (IoT) are becoming standard in modern factories.

Key Automated Technologies in Sheet Metal Forming

1. CNC Press Brakes and Punching Machines

CNC technology is the backbone of automation in sheet metal forming. CNC press brakes and punching machines are programmed to perform precise bends and cuts with minimal human intervention. These machines use servo-electric or hydraulic drives to achieve high accuracy and repeatability. Advanced models feature automatic tool changers, which allow for quick switching between different forming operations without manual setup.

2. Robotic Automation

Robots are increasingly deployed in sheet metal forming for tasks such as loading and unloading raw materials, transferring parts between machines, and stacking finished products. Collaborative robots (cobots) work alongside human operators, enhancing productivity while ensuring safety. Vision systems integrated with robots enable them to identify and handle parts with complex geometries.

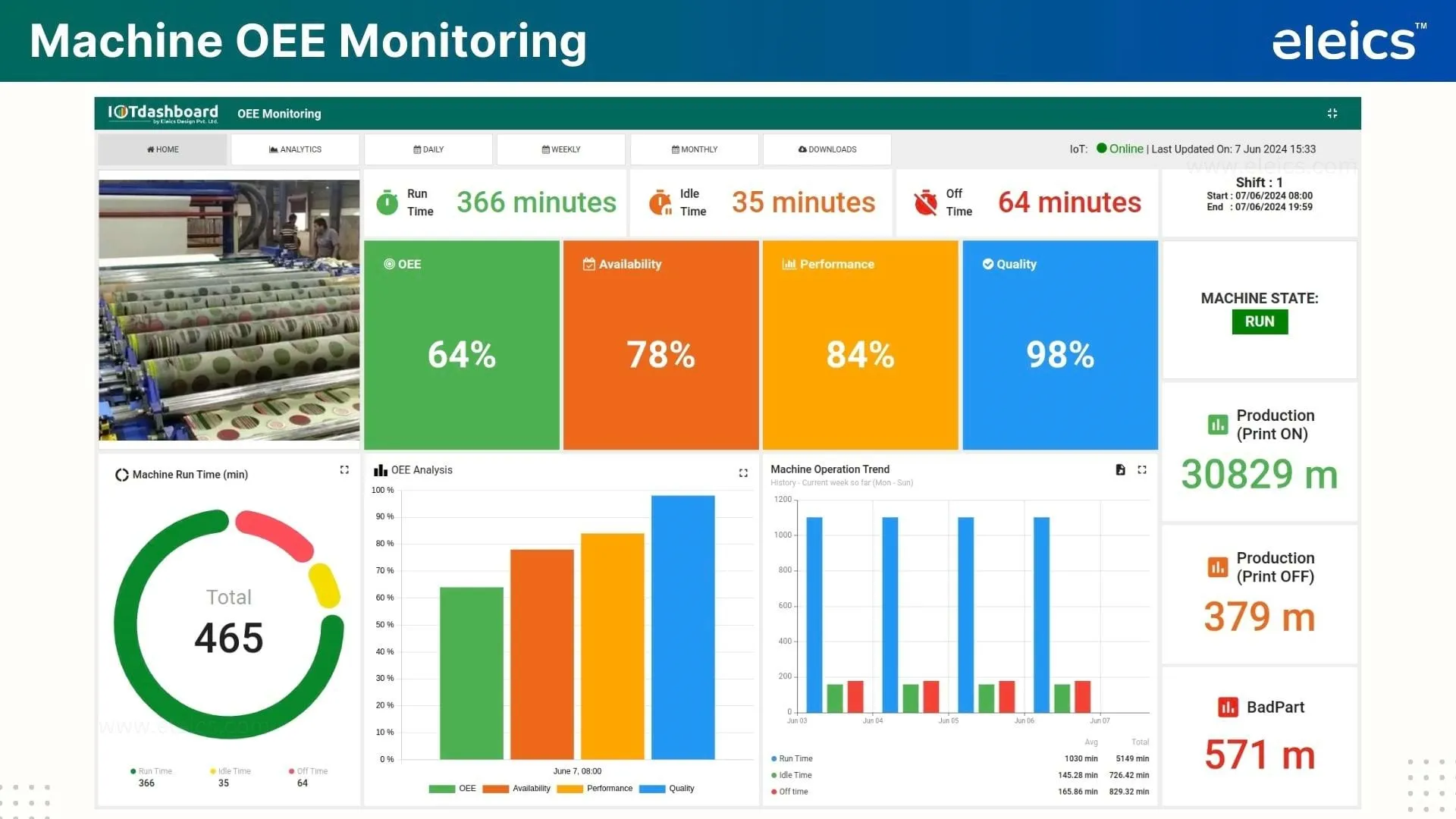

3. IoT and Industry 4.0 Integration

The integration of IoT sensors and cloud computing allows sheet metal forming machines to be part of smart factories. Real-time data collection on parameters like machine performance, energy consumption, and tool wear enables predictive maintenance, reducing downtime and extending equipment life. Industry 4.0 principles facilitate seamless communication between machines, leading to optimized production schedules and resource allocation.

4. AI and Machine Learning

AI algorithms are used to optimize forming processes by predicting the best parameters for material deformation, reducing trial and error. Machine learning models analyze historical data to improve quality control, detecting defects such as cracks or wrinkles early in the process. This results in higher yield rates and reduced material waste.

Benefits of Automation in Sheet Metal Forming

Automation brings numerous advantages to sheet metal forming operations, including:

| Benefit | Description |

|---|---|

| Increased Productivity | Automated systems operate continuously at high speeds, significantly boosting output compared to manual methods. |

| Enhanced Precision | CNC and robotic systems achieve micron-level accuracy, ensuring consistent part quality. |

| Improved Safety | Reducing human involvement in hazardous tasks minimizes the risk of workplace injuries. |

| Cost Efficiency | Lower labor costs, reduced material waste, and predictive maintenance lead to overall cost savings. |

| Flexibility | Quick reprogramming allows for easy switching between different product designs, supporting mass customization. |

Challenges and Future Trends

Despite its benefits, automation in sheet metal forming faces challenges such as high initial investment, the need for skilled technicians to manage advanced systems, and cybersecurity risks in connected environments. However, ongoing research is addressing these issues. Future trends include the adoption of additive manufacturing (3D printing) for hybrid forming processes, increased use of digital twins for simulation and optimization, and the development of more intuitive human-machine interfaces.

Conclusion

Automation has revolutionized sheet metal forming, making it faster, safer, and more efficient. As technologies like AI, IoT, and robotics continue to evolve, the capabilities of automated forming machines will expand, further enhancing their role in modern manufacturing. Embracing these advancements is essential for companies aiming to stay competitive in the global market.