CNC Tube Bending Machine India - Revolutionizing Manufacturing

The manufacturing landscape in India has witnessed a significant transformation with the adoption of advanced technologies, and CNC (Computer Numerical Control) tube bending machines stand at the forefront of this revolution. These machines have become indispensable in industries requiring high-precision metal forming, offering unparalleled accuracy, efficiency, and versatility. This article explores the impact, applications, and advantages of CNC tube bending machines in the Indian context.

What is a CNC Tube Bending Machine?

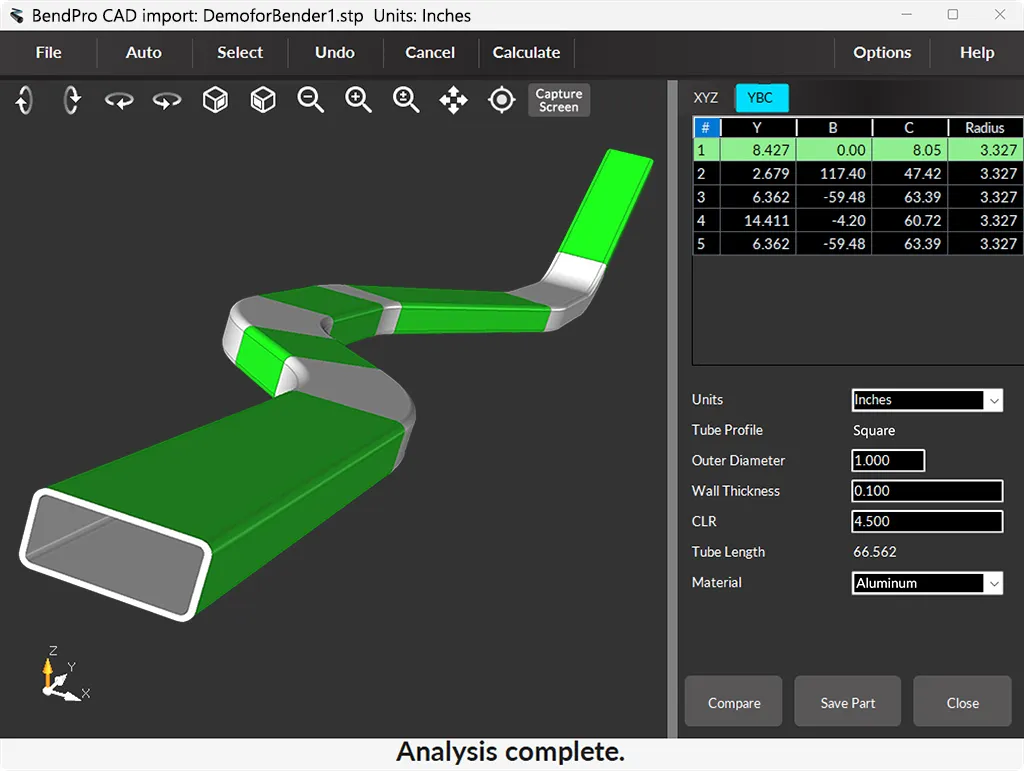

A CNC tube bending machine is a sophisticated piece of equipment used to bend tubes and pipes to precise angles and shapes with minimal human intervention. Unlike manual or hydraulic benders, CNC machines are controlled by computer programs, ensuring consistent and repeatable results. The process involves feeding a tube into the machine, where it is clamped and bent around a die according to programmed specifications.

Key Features and Technological Advancements

CNC tube bending machines in India incorporate several advanced features that enhance their performance:

- Precision Control: Servo-electric systems provide exact control over bending angles, ensuring accuracy within fractions of a degree.

- Multi-Axis Bending: Capable of handling complex bends in multiple planes, reducing the need for secondary operations.

- Automated Feed and Rotation: Integrated systems automatically adjust the tube's position for consecutive bends.

- Real-Time Monitoring: Sensors and software monitor the bending process, detecting errors and preventing defects.

Common Specifications of CNC Tube Bending Machines in India

| Parameter | Range | Application |

|---|---|---|

| Tube Diameter | 5 mm to 200 mm | Small components to large pipelines |

| Bending Radius | 0.5D to 5D | Tight to large radius bends |

| Accuracy | ±0.1° | High-precision industries |

| Control System | CNC with touch interface | User-friendly operation |

Applications in Indian Industries

CNC tube bending machines are utilized across various sectors in India:

- Automotive: Manufacturing exhaust systems, chassis frames, and fluid lines.

- Aerospace: Creating lightweight and precise tubing for aircraft systems.

- Construction: Bending structural pipes and handrails.

- Furniture: Designing metallic furniture with aesthetic bends.

Advantages of Using CNC Tube Bending Machines

The adoption of CNC tube bending technology offers numerous benefits:

- High Precision: Computer-controlled processes eliminate human error.

- Efficiency: Faster production cycles compared to manual bending.

- Cost-Effectiveness: Reduced material waste and lower labor costs.

- Flexibility: Quick changeover between different bending programs.

Challenges and Future Outlook

Despite the advantages, challenges such as high initial investment and the need for skilled operators exist. However, with government initiatives like 'Make in India' promoting advanced manufacturing, the future looks promising. Innovations in AI and IoT are expected to further enhance the capabilities of CNC tube bending machines, making them smarter and more connected.

Conclusion

CNC tube bending machines have revolutionized manufacturing in India, providing the precision and efficiency required in modern industries. As technology continues to evolve, these machines will play an even more critical role in shaping the future of manufacturing, driving growth and innovation across sectors.