Cold Heading Machine China: Revolutionizing Metal Forming Technology

The manufacturing industry has witnessed significant transformations over the past decades, with cold heading technology emerging as one of the most efficient metal forming processes. China has positioned itself as a global powerhouse in the production of cold heading machines, offering advanced technology, competitive pricing, and reliable performance. This article explores the capabilities, advantages, and technological innovations of cold heading machines manufactured in China.

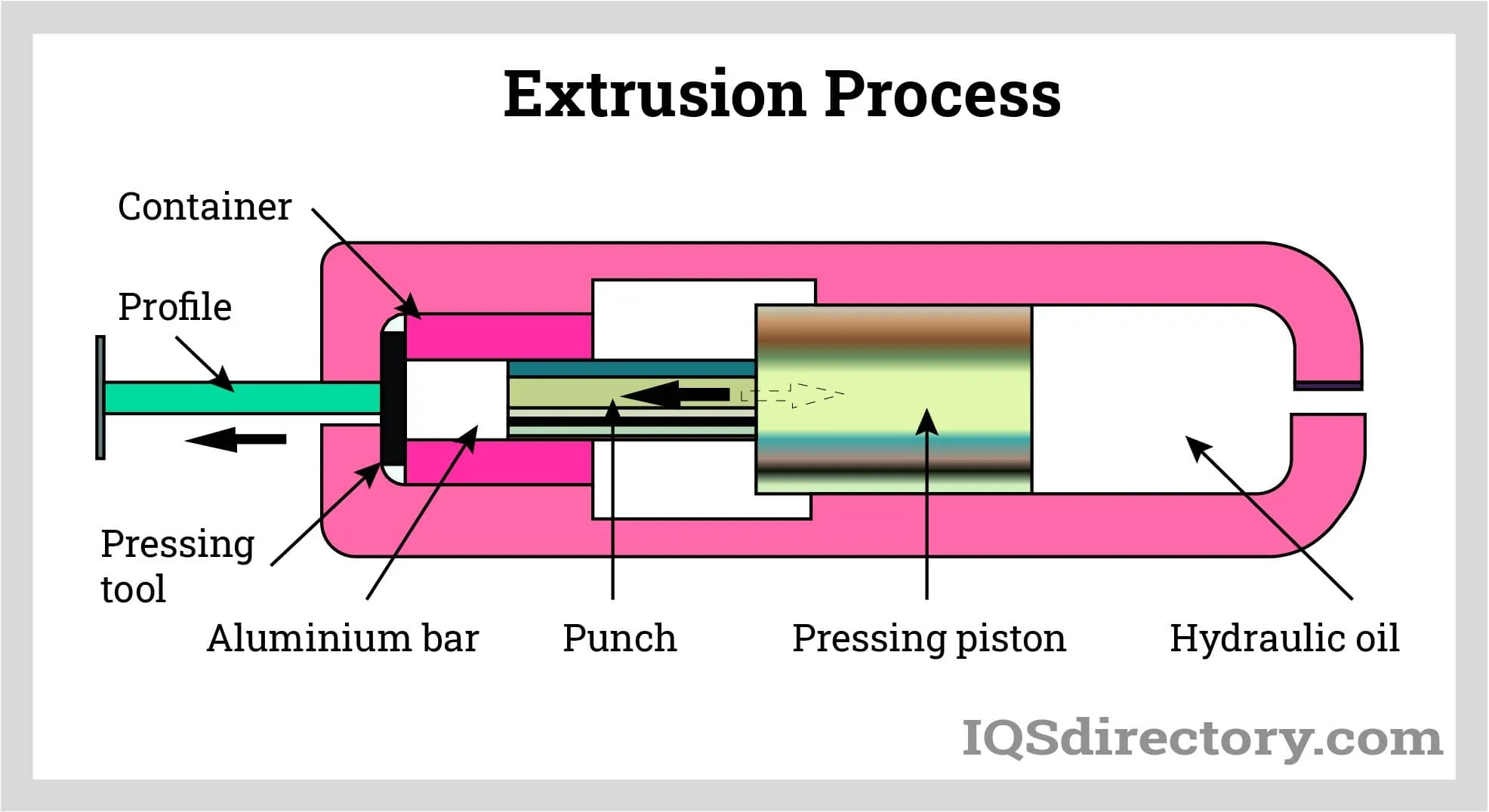

What is Cold Heading Technology?

Cold heading, also known as cold forming, is a manufacturing process that shapes metal at room temperature using progressive dies. Unlike traditional machining that removes material, cold heading displaces and forms metal through high-pressure compression, resulting in minimal waste and superior mechanical properties in the finished products.

Key Advantages of Chinese Cold Heading Machines

Cost-Effectiveness and Value

Chinese manufacturers have mastered the art of producing high-quality cold heading machines at competitive prices. Through optimized production processes and economies of scale, they offer exceptional value without compromising on quality or performance.

Technological Innovation

China's cold heading machine industry has invested heavily in research and development, incorporating advanced features such as CNC controls, automated feeding systems, and real-time monitoring capabilities that enhance precision and productivity.

Customization Capabilities

Chinese manufacturers excel at providing customized solutions tailored to specific production requirements. From specialized tooling to unique machine configurations, they offer flexibility that meets diverse industrial needs.

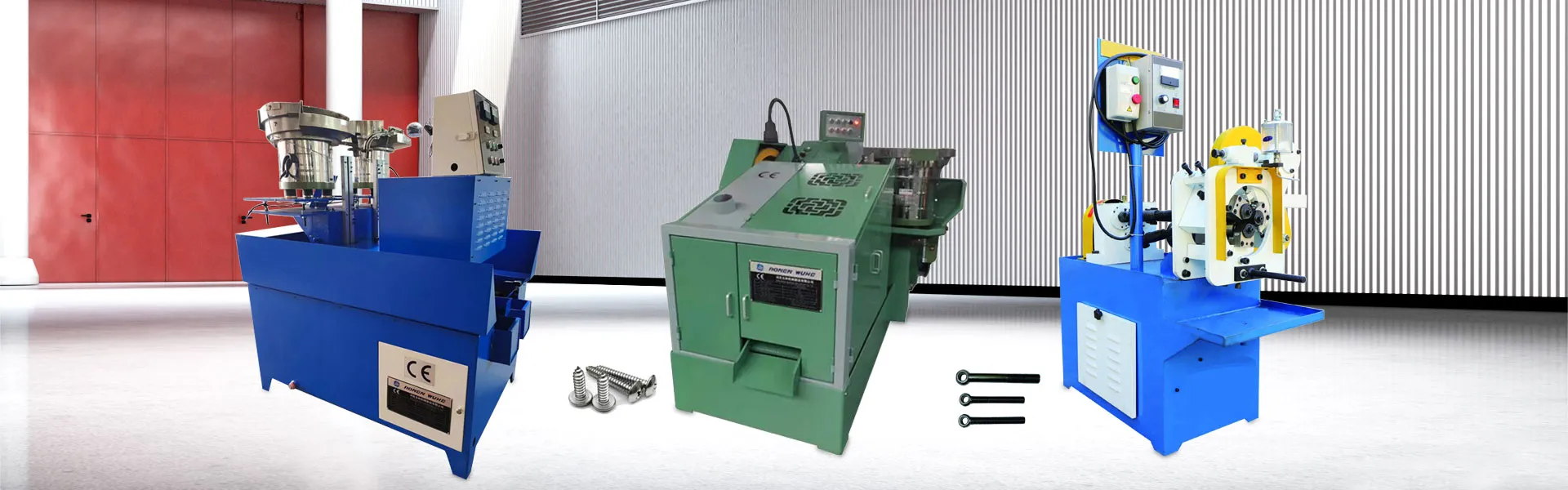

Applications of Cold Heading Machines

Cold heading machines produced in China serve numerous industries worldwide, manufacturing critical components with precision and efficiency:

| Industry | Applications | Common Materials |

|---|---|---|

| Automotive | Bolts, screws, studs, fasteners | Carbon steel, alloy steel |

| Aerospace | Specialized fasteners, precision components | Titanium, high-strength alloys |

| Construction | Anchor bolts, structural fasteners | Stainless steel, galvanized steel |

| Electronics | Small precision screws, connectors | Brass, copper, aluminum |

| Consumer Goods | Hardware, appliance components | Various steels, non-ferrous metals |

Technical Specifications of Modern Chinese Cold Heading Machines

Contemporary cold heading machines from China incorporate sophisticated engineering and advanced features that ensure optimal performance across various applications:

| Parameter | Standard Range | Advanced Models |

|---|---|---|

| Production Speed | 50-200 pieces/minute | Up to 400 pieces/minute |

| Wire Diameter Capacity | 1mm - 20mm | 0.5mm - 30mm |

| Maximum Forming Pressure | 50-200 tons | Up to 300 tons |

| Control System | PLC-based | CNC with touchscreen interface |

| Automation Level | Semi-automatic | Fully automatic with robotics |

| Energy Consumption | Standard efficiency | Energy-saving designs |

Quality Assurance and International Standards

Chinese cold heading machine manufacturers adhere to strict quality control protocols and international standards, ensuring their equipment meets global requirements for performance, safety, and reliability. Most reputable companies hold ISO 9001 certification and comply with CE, UL, or other relevant international standards.

Future Trends in Chinese Cold Heading Technology

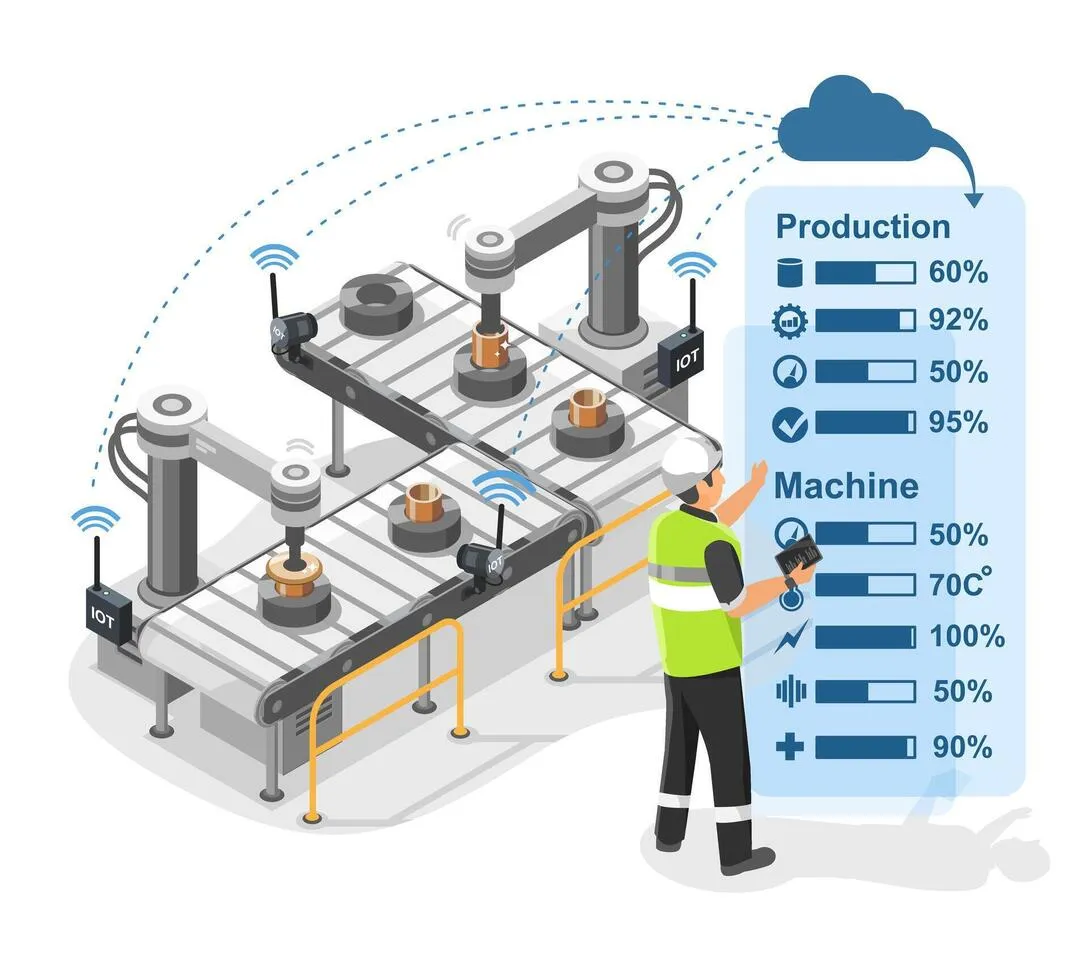

Industry 4.0 Integration

Chinese manufacturers are increasingly incorporating Industry 4.0 principles, with smart factories featuring IoT connectivity, data analytics, and predictive maintenance capabilities that maximize uptime and productivity.

Sustainability Initiatives

The industry is moving toward more environmentally friendly practices, including energy-efficient designs, reduced material waste, and recycling systems that minimize environmental impact.

Advanced Material Compatibility

Research continues to expand the range of materials that can be processed, including high-strength alloys, composites, and specialized materials for demanding applications.

Selecting the Right Chinese Cold Heading Machine Manufacturer

When sourcing cold heading machines from China, consider these critical factors:

- Manufacturer reputation and industry experience

- Technical support and after-sales service

- Customization capabilities

- Compliance with international standards

- Spare parts availability and lead times

- Training and documentation provided

Conclusion

China has established itself as a global leader in cold heading machine manufacturing, combining technological innovation with cost-effective production. The country's manufacturers continue to push the boundaries of what's possible in metal forming technology, offering solutions that meet the evolving needs of industries worldwide. With ongoing investments in research and development, Chinese cold heading machines represent excellent value for manufacturers seeking to enhance their production capabilities while maintaining competitive operational costs.