Comparative Review of Sheet Metal Forming Machines

The manufacturing industry relies heavily on sheet metal forming processes to create components for automotive, aerospace, construction, and consumer goods. Selecting the right forming machine is critical for achieving desired product quality, production efficiency, and cost-effectiveness. This article provides a detailed comparative analysis of the primary types of sheet metal forming machines available today, examining their principles, capabilities, and ideal applications.

1. Fundamental Forming Technologies

Sheet metal forming encompasses various technologies that deform metal sheets into desired shapes without removing material. The core mechanical processes involve the application of force to exceed the metal's yield strength, causing permanent deformation.

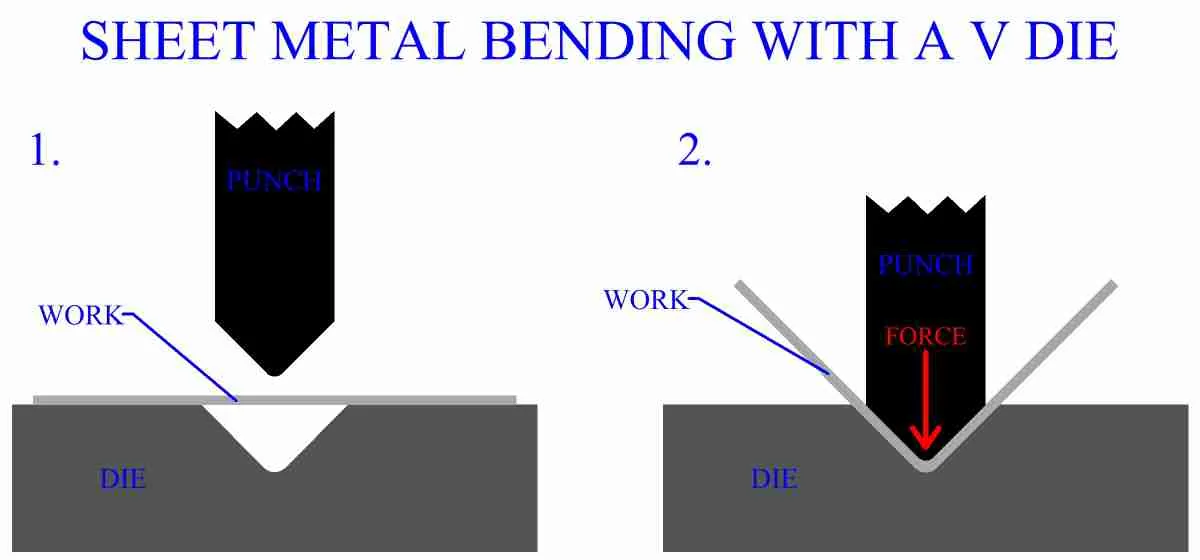

Figure 1: Fundamental principle of sheet metal bending under applied force.

1.1 Press Brakes

Press brakes are the most common machines for bending sheet metal. They work by clamping the workpiece between a matching punch and die. Modern press brakes are predominantly powered by hydraulic, electric servo, or hybrid systems, each offering distinct advantages in speed, accuracy, and energy consumption.

1.2 Stamping Presses

Stamping presses perform operations like blanking, piercing, and deep drawing using dedicated dies. They are characterized by their high production rates and are essential for mass manufacturing. The key types include mechanical, hydraulic, and servo-driven presses.

Figure 2: An industrial stamping press used for high-volume automotive part production.

2. Comparative Analysis of Machine Types

The following table provides a side-by-side comparison of the main sheet metal forming machine categories based on critical operational parameters.

| Machine Type | Primary Process | Typical Tonnage | Production Speed | Flexibility | Best For |

|---|---|---|---|---|---|

| Hydraulic Press Brake | Bending | 10 - 3000 Tons | Medium | High | Medium-batch, varied bends |

| Electric Servo Press Brake | Bending | 10 - 600 Tons | High | Very High | High-mix, precision bending |

| Mechanical Stamping Press | Blanking, Piercing | 20 - 5000+ Tons | Very High | Low | High-volume, simple parts |

| Hydraulic Stamping Press | Deep Drawing, Forming | 100 - 10,000+ Tons | Low-Medium | Medium | Complex, deep-drawn parts |

| Servo-Driven Press | Versatile Forming | 30 - 3000 Tons | High | High | Precision forming with programmable motion |

3. Key Selection Criteria

Choosing the appropriate machine requires a careful evaluation of several factors beyond basic capability.

3.1 Precision and Accuracy

Electric servo-driven machines, especially servo press brakes, offer superior precision with repeatability within microns. This is crucial for industries like aerospace and electronics. Hydraulic systems provide robust force but may require more maintenance to sustain accuracy over time.

Figure 3: High-precision bending on a modern servo-electric press brake.

3.2 Flexibility and Setup Time

For job shops with frequent product changeovers, flexibility is paramount. Machines with CNC controls, automatic tool changers, and servo drives significantly reduce setup time. Hydraulic press brakes are versatile but slower to adjust compared to their servo-electric counterparts.

3.3 Energy Efficiency and Total Cost of Ownership

Electric servo motors consume energy only during the actual forming cycle, unlike hydraulic systems that run pumps continuously. This can lead to energy savings of 30-60%. The total cost of ownership must factor in energy consumption, maintenance, tooling, and potential downtime.

4. Technological Advancements and Industry 4.0

The integration of IoT sensors, AI, and cloud connectivity is transforming sheet metal forming. Modern machines feature predictive maintenance alerts, real-time monitoring of force and angle, and adaptive control systems that compensate for material variability.

Figure 4: Smart dashboard providing real-time analytics and machine health monitoring.

This digital transformation enables unprecedented levels of productivity, quality control, and integration with factory-wide MES (Manufacturing Execution Systems).

5. Conclusion and Recommendations

The selection of a sheet metal forming machine is not a one-size-fits-all decision. For high-volume, dedicated production of simple parts, mechanical or hydraulic stamping presses remain unbeatable. For environments requiring high flexibility, precision, and energy efficiency—such as contract manufacturing or prototyping—electric servo press brakes and servo-driven presses offer significant advantages. The future lies in smart, connected machines that enhance operational transparency and adaptability. Manufacturers must align their investment with specific production needs, material types, part complexity, and long-term strategic goals to maximize return on investment and maintain competitive advantage.