Comparing Manual vs. CNC Tube Bending Techniques

Introduction to Tube Bending Methods

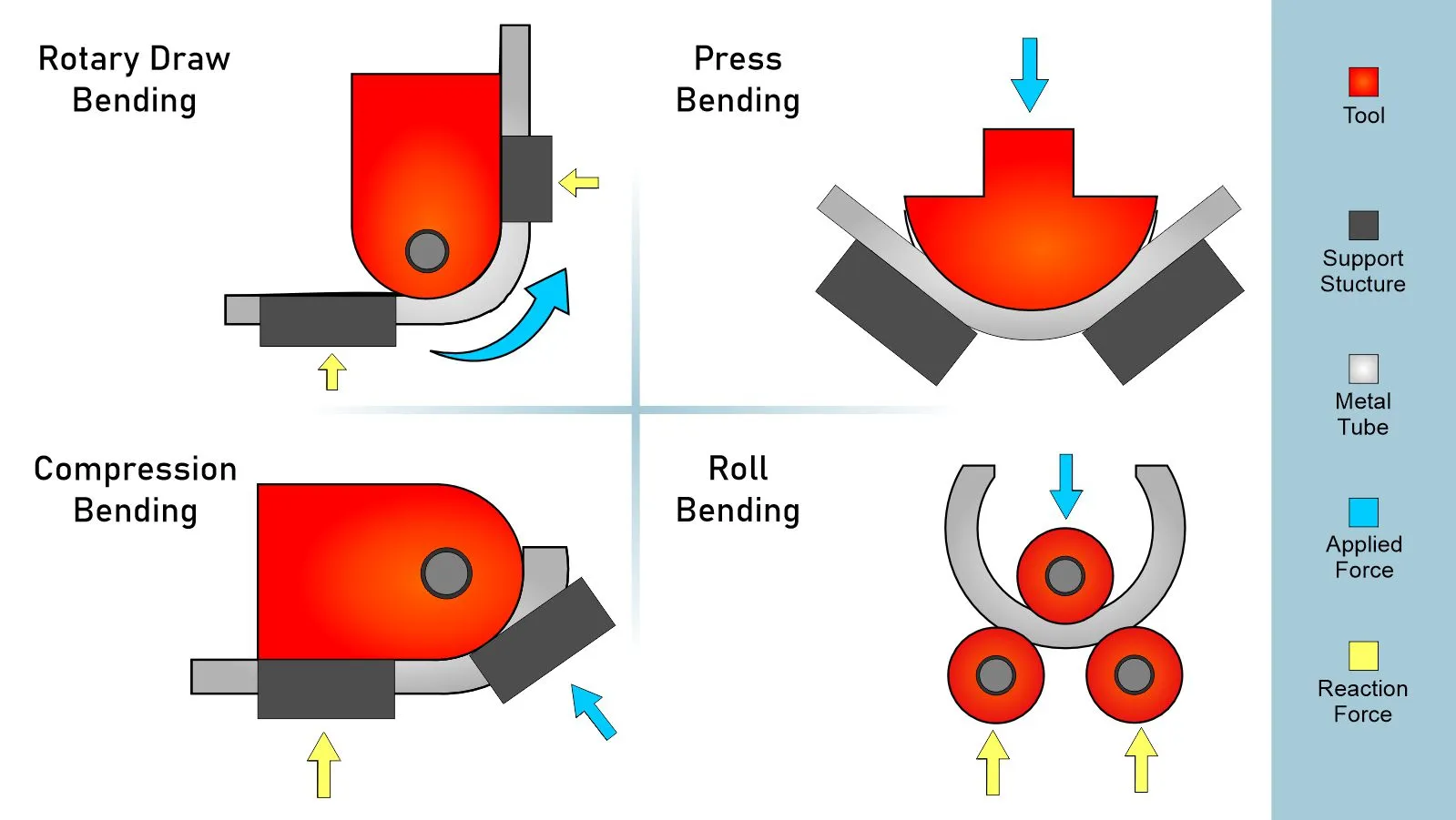

Tube bending is a critical manufacturing process used across various industries including automotive, aerospace, construction, and furniture manufacturing. The evolution of bending technologies has led to two primary methods: manual bending and Computer Numerical Control (CNC) bending. Each technique offers distinct advantages and limitations, making them suitable for different applications and production requirements.

Understanding Manual Tube Bending

Traditional Approach and Equipment

Manual tube bending represents the traditional approach to shaping metal tubes and pipes. This method relies on human operators using mechanical tools such as hand benders, hydraulic benders, or simple lever-based equipment. The process requires significant skill and experience to achieve accurate bends consistently.

Skill Requirements and Operator Expertise

Manual bending demands highly skilled operators who can interpret technical drawings, calculate springback, and apply appropriate force and positioning. These craftsmen develop an intuitive understanding of material behavior through years of experience, allowing them to make real-time adjustments during the bending process.

Exploring CNC Tube Bending Technology

Automated Precision and Control

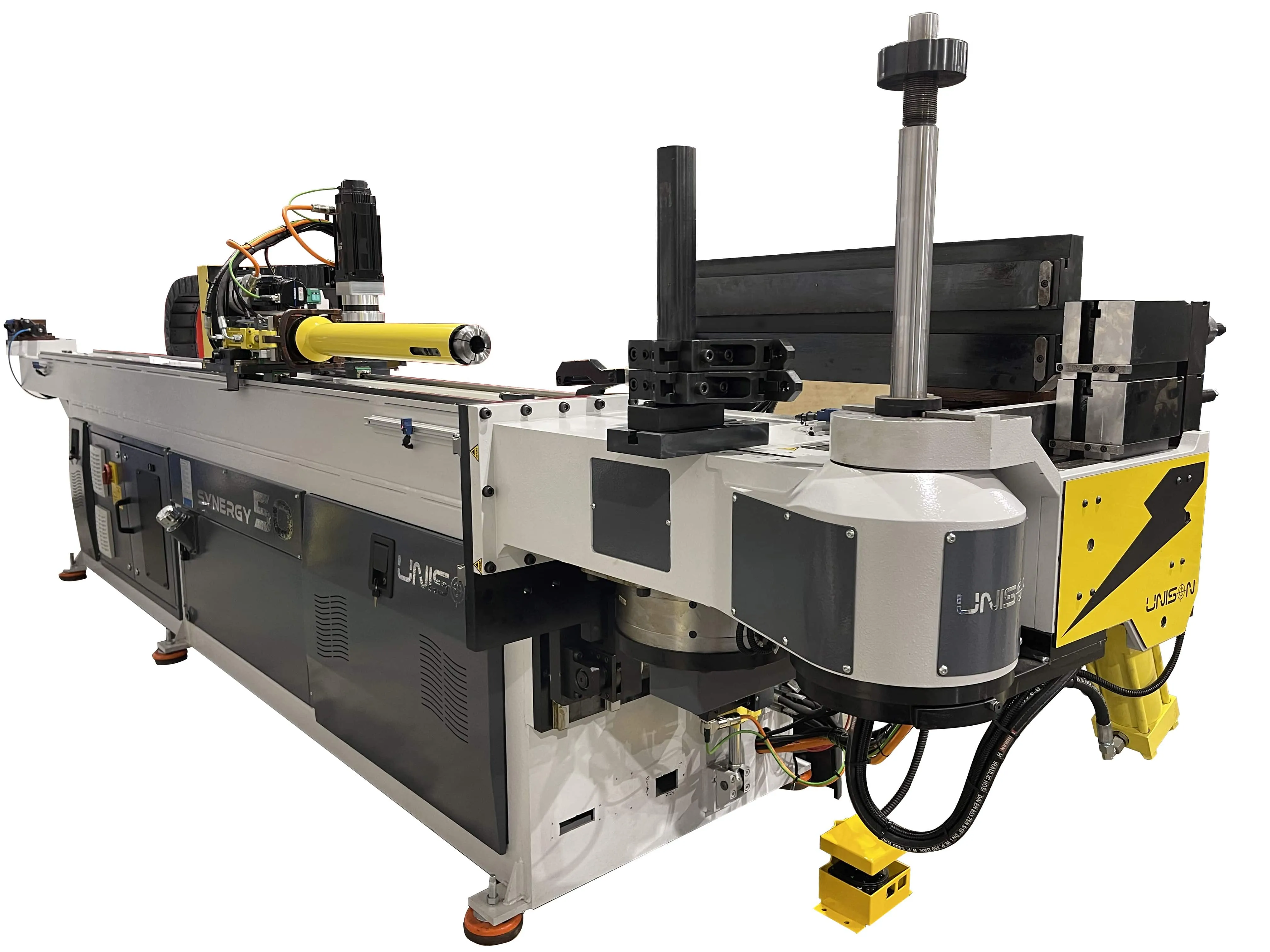

CNC tube bending represents the modern, automated approach to tube fabrication. These computer-controlled systems use servo motors, hydraulic systems, and sophisticated software to execute precise bends according to digital designs. The technology eliminates much of the human variability inherent in manual methods.

Programming and Setup Process

CNC bending begins with CAD/CAM programming where operators input bending parameters, angles, and dimensions. The machine then automatically positions the tube, applies calculated pressure, and executes bends with minimal human intervention. Advanced systems include real-time monitoring and correction capabilities.

Comparative Analysis: Key Differences

Accuracy and Repeatability

The precision capabilities of each method represent one of the most significant differences. Manual bending typically achieves tolerances of ±1-2 degrees, while CNC systems can maintain tolerances within ±0.1 degrees. This precision advantage makes CNC bending essential for applications requiring exact specifications and consistent repeatability.

Production Speed and Efficiency

While manual bending requires setup time for each new job, CNC machines can store multiple programs and switch between them quickly. For high-volume production runs, CNC bending significantly outperforms manual methods in terms of throughput and efficiency.

| Parameter | Manual Bending | CNC Bending |

|---|---|---|

| Tolerance Accuracy | ±1-2 degrees | ±0.1 degrees |

| Setup Time | 15-45 minutes | 5-15 minutes |

| Production Rate | 10-20 bends/hour | 50-100 bends/hour |

| Operator Skill Level | High (years of experience) | Medium (technical training) |

| Initial Investment | $5,000 - $20,000 | $50,000 - $300,000+ |

| Ideal Application | Prototypes, small batches, repairs | High-volume production, complex geometries |

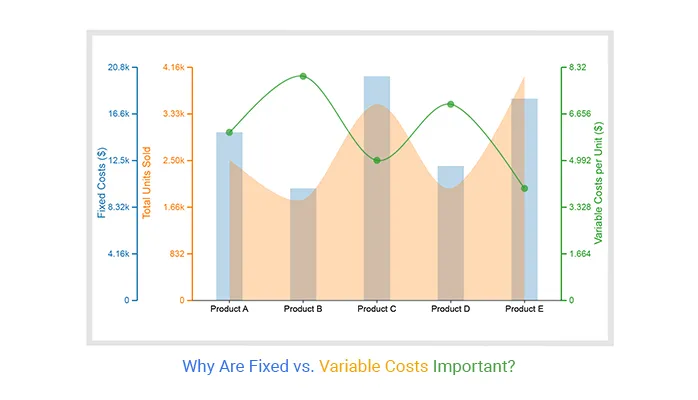

Cost Considerations and Economic Factors

Initial Investment and Operating Costs

The financial aspects of each method vary significantly. Manual bending equipment requires lower initial investment, making it accessible for small shops and businesses with limited capital. CNC systems represent a substantial financial commitment but offer lower per-part costs in high-volume production scenarios.

Labor Costs and Training Requirements

Manual bending relies on highly skilled (and often higher-paid) craftsmen, while CNC operations require technically trained operators who can program and maintain sophisticated equipment. The training curve for CNC operators is generally shorter than developing manual bending expertise.

Application-Specific Considerations

When to Choose Manual Bending

Manual bending remains preferable for specific applications including prototyping, custom one-off projects, repair work, and situations requiring on-site bending. The flexibility and lower tooling costs make manual methods ideal for low-volume, high-variety production environments.

When CNC Bending is Essential

CNC bending becomes necessary for high-volume production, applications requiring extreme precision, complex multi-plane bends, and industries with strict quality control requirements such as aerospace and medical equipment manufacturing.

| Industry | Manual Bending Applications | CNC Bending Applications |

|---|---|---|

| Automotive | Custom exhaust systems, restoration projects | Production exhaust systems, fuel lines, brake lines |

| Aerospace | Prototype hydraulic lines, repair work | Production hydraulic systems, structural components |

| Construction | On-site modifications, custom railings | Prefabricated structural elements, standardized components |

| Furniture | Custom designs, artistic pieces | Mass-produced frames, standardized parts |

Future Trends and Technological Developments

Hybrid Approaches and Smart Technology

The future of tube bending likely involves hybrid systems that combine the flexibility of manual control with the precision of digital technology. Advanced sensors, artificial intelligence, and real-time monitoring systems are being integrated into both manual and CNC equipment to improve accuracy and efficiency.

Sustainability and Material Innovations

Both bending methods are evolving to accommodate new materials and sustainability requirements. The industry is developing more energy-efficient machines and techniques for bending advanced alloys and composite materials that are increasingly common in modern manufacturing.

Conclusion: Choosing the Right Method

The choice between manual and CNC tube bending depends on multiple factors including production volume, accuracy requirements, budget constraints, and available expertise. While CNC bending dominates modern high-volume manufacturing, manual bending maintains its relevance for specialized applications requiring human judgment and flexibility. Understanding the capabilities and limitations of each method enables manufacturers to select the most appropriate technology for their specific needs.