Complete Guide to the DORST Press Manual PDF | Operation & Maintenance

For operators, technicians, and engineers working with advanced hydraulic pressing equipment, the DORST press manual PDF is an indispensable resource. This comprehensive document provides critical instructions for the safe, efficient, and correct operation of DORST hydraulic presses, which are widely used in powder metallurgy, ceramic, and advanced materials forming. Accessing and thoroughly understanding this manual is not just a recommendation—it is a fundamental requirement for ensuring personnel safety, maximizing press productivity, and extending the machinery's operational lifespan. This guide delves into the key sections typically found in a DORST press manual, explaining their importance and practical application.

Key Sections of a Typical DORST Press Manual PDF

The structure of the manual is logical, guiding the user from initial setup to complex troubleshooting. While specific models may have variations, the core components remain consistent.

1. Safety Instructions and Regulations

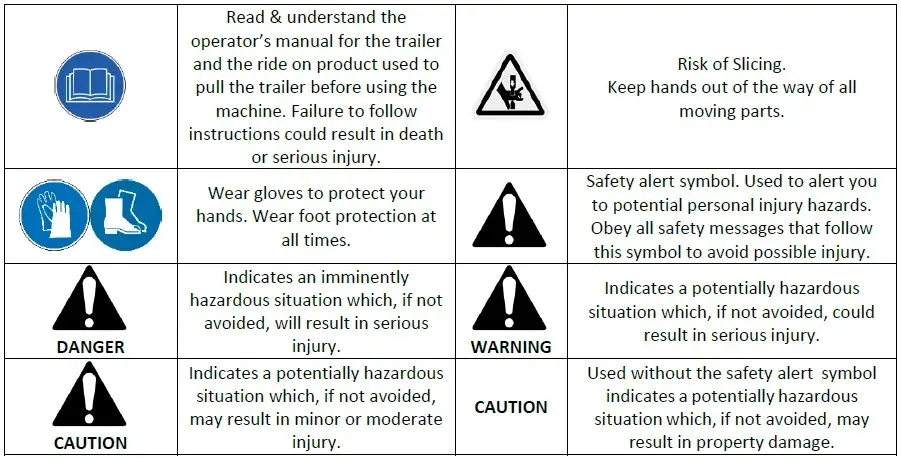

This is the most critical section. It outlines potential hazards, mandatory personal protective equipment (PPE), and safe work practices. Ignoring these guidelines can lead to severe injury or equipment damage.

2. Technical Data and Press Description

This section provides the press's fingerprint: its model number, maximum pressure (kN or tons), daylight, stroke length, table size, and power requirements. Understanding these specifications is essential for tooling design and process planning.

3. Installation and Commissioning

Detailed steps for initial setup, including foundation requirements, leveling, electrical connection, and hydraulic system filling and bleeding. Proper commissioning is vital for long-term accuracy and reliability.

4. Control System and Operation

The heart of the manual. It explains the functions of the control panel, how to set pressing parameters (pressure, time, speed), and the step-by-step procedure for manual and automatic operation cycles.

| Parameter | Unit | Description | Typical Influence |

|---|---|---|---|

| Pressing Pressure | kN / MPa | Final force applied to the powder | Part density and mechanical strength |

| Filling Depth | mm | Initial die cavity fill height | Part height and weight |

| Decompression Speed | mm/s | Speed at which pressure is released | Prevents cracking and laminations |

| Dwell Time | seconds | Time at maximum pressure | Ensures pressure uniformity |

5. Tooling Setup and Changeover

Instructions for installing, aligning, and securing upper punches, lower punches, and dies. Proper tooling setup is crucial for producing dimensionally accurate and consistent parts.

6. Maintenance Schedule and Procedures

This section provides a structured plan for preventative maintenance. It includes daily checks, weekly lubrication points, and periodic inspections of hydraulic fluids, seals, and mechanical components.

7. Troubleshooting and Fault Codes

An essential reference for diagnosing problems. It typically lists symptoms (e.g., low pressure, unusual noise), probable causes (e.g., hydraulic leak, solenoid valve failure), and recommended corrective actions.

Why the PDF Format is Crucial

The availability of the DORST press manual in PDF format offers significant advantages:

- Accessibility: Can be stored on multiple devices (shop floor computers, tablets) for instant access.

- Searchability: Users can quickly find keywords like "pressure calibration" or "error code E05."

- Preservation: Digital copies do not degrade, get lost, or become soiled like paper manuals.

- Distribution: Easy to share with authorized personnel across different shifts or locations.

Best Practices for Using the DORST Press Manual

To fully leverage the manual, integrate it into your daily workflow:

- Ensure the latest version is always available to all relevant staff.

- Incorporate safety and key operational procedures into training programs.

- Keep a log of maintenance activities as recommended in the manual.

- Use the troubleshooting guide systematically before attempting complex repairs.

In conclusion, the DORST press manual PDF is far more than a simple booklet; it is the definitive operational blueprint for your critical pressing equipment. Mastery of its contents empowers teams to work safely, optimize processes, perform effective maintenance, and minimize costly downtime. Treating this document as a living, essential tool is a hallmark of professional and efficient press shop management.