Cost-Benefit Analysis of Investing in a Progressive Die Press

Cost-Benefit Analysis of Investing in a Progressive Die Press

In the competitive landscape of modern manufacturing, companies constantly seek ways to improve efficiency, reduce costs, and enhance product quality. One significant investment that manufacturing firms consider is the acquisition of a progressive die press. This sophisticated machinery represents a substantial capital expenditure but offers the potential for remarkable long-term benefits. This article provides a comprehensive cost-benefit analysis of investing in a progressive die press, examining both the financial implications and operational advantages to help manufacturers make informed decisions.

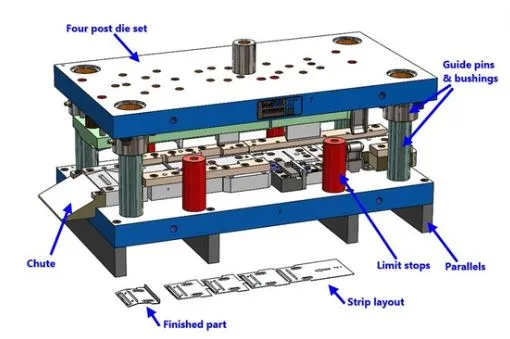

Understanding Progressive Die Press Technology

A progressive die press is a specialized stamping machine that performs a series of operations at multiple stations within a single press system. With each stroke of the press, a metal strip advances through various stations, with each station performing a specific operation such as punching, bending, coining, or cutting. The part is progressively formed until it emerges as a finished product at the final station.

This technology is particularly valuable for high-volume production of metal components used in industries such as automotive, aerospace, electronics, and appliances. The efficiency of progressive die pressing comes from its ability to complete multiple operations simultaneously, significantly reducing production time compared to traditional single-operation presses.

Initial Investment Costs

Equipment Acquisition

The most substantial upfront cost is the purchase of the progressive die press itself. Prices vary significantly based on size, capacity, and features:

| Press Type | Capacity Range | Price Range | Typical Applications |

|---|---|---|---|

| Mechanical | 20-200 tons | $50,000-$200,000 | Small to medium components |

| Hydraulic | 100-1000 tons | $100,000-$500,000 | Larger, more complex parts |

| Servo-Driven | 30-600 tons | $150,000-$600,000+ | Precision components |

Tooling and Die Costs

Progressive dies themselves represent a significant investment, often ranging from $20,000 to $200,000 or more depending on complexity. These precision tools require skilled design and manufacturing, typically accounting for 15-30% of the total initial investment.

Installation and Setup

Additional costs include foundation preparation, electrical connections, safety systems, and initial setup. These expenses can range from $10,000 to $50,000 depending on the press size and facility requirements.

Training and Implementation

Proper operator and maintenance training is essential for safe and efficient operation. Companies should budget $5,000-$20,000 for comprehensive training programs.

Operational Costs

Labor Expenses

While progressive die presses reduce labor requirements compared to multiple single-operation presses, they still require skilled operators and maintenance personnel. A single operator can often manage multiple presses, leading to significant labor savings.

Maintenance and Repairs

Regular maintenance is crucial for optimal performance and longevity. Annual maintenance costs typically range from 2-5% of the initial equipment cost.

Energy Consumption

Progressive die presses consume substantial electricity, especially larger models. Energy costs vary based on local rates and production volume but represent an ongoing operational expense.

Material Costs

While material usage itself isn't unique to progressive die pressing, the technology often enables more efficient material utilization through optimized nesting and reduced scrap rates.

Quantifiable Benefits

Increased Production Efficiency

Progressive die presses dramatically increase production rates. A single progressive press can often replace 3-5 traditional presses, producing completed parts with each stroke at rates of 50-1,200 strokes per minute depending on part complexity and press specifications.

Reduced Labor Costs

The automation capabilities of progressive die pressing significantly reduce direct labor requirements. One operator can typically manage multiple presses, leading to labor cost reductions of 50-70% compared to traditional stamping methods.

Improved Quality and Consistency

Progressive die presses produce parts with exceptional consistency and minimal variation. The automated process reduces human error, resulting in higher quality products and reduced rejection rates.

Space Efficiency

By combining multiple operations into a single machine, progressive die presses require significantly less floor space than multiple single-operation presses. This space saving can be particularly valuable in facilities with high real estate costs.

Reduced Work-in-Process Inventory

Since parts are completed in a single press, there is minimal work-in-process inventory, reducing carrying costs and improving cash flow.

Financial Analysis Framework

Payback Period Calculation

The payback period represents the time required to recoup the initial investment through generated savings and increased profits. A typical payback period for a progressive die press investment ranges from 1-3 years for high-volume applications.

Return on Investment (ROI)

ROI calculations should consider both tangible and intangible benefits. Progressive die presses often deliver ROI percentages of 25-50% or higher for suitable applications.

Net Present Value (NPV) Analysis

NPV analysis accounts for the time value of money, providing a more comprehensive financial picture. A positive NPV indicates that the investment is expected to generate value beyond the required rate of return.

Internal Rate of Return (IRR)

IRR represents the annualized effective compounded return rate. Investments with IRR exceeding the company's hurdle rate are generally considered financially viable.

Non-Financial Considerations

Competitive Advantage

Investing in progressive die technology can provide significant competitive advantages through faster production times, lower costs, and higher quality products.

Flexibility and Scalability

Modern progressive die presses offer quick changeover capabilities, allowing manufacturers to respond rapidly to changing market demands and production requirements.

Safety Improvements

Advanced safety features in modern progressive die presses, including light curtains, interlocked guards, and robotic part removal, can significantly enhance workplace safety compared to traditional presses.

Risk Assessment

Technical Risks

Progressive die presses require sophisticated tooling and skilled maintenance. Companies must assess their technical capabilities or partner with experienced suppliers to mitigate these risks.

Market Risks

The high production volumes enabled by progressive die pressing require consistent demand. Fluctuations in market conditions can impact the economic viability of the investment.

Technological Obsolescence

With rapid advancements in manufacturing technology, companies must consider the equipment's expected lifespan and potential for future upgrades.

Case Study: Automotive Component Manufacturer

A mid-sized automotive component manufacturer recently invested in a 300-ton servo-driven progressive die press at a total cost of $450,000 (including tooling and installation). The analysis revealed:

| Metric | Before Investment | After Investment | Improvement |

|---|---|---|---|

| Production Rate | 800 parts/hour | 2,200 parts/hour | 175% increase |

| Labor Cost/Part | $0.35 | $0.12 | 66% reduction |

| Scrap Rate | 4.2% | 1.8% | 57% reduction |

| Payback Period | 1.8 years | ||

| Projected 5-year ROI | 42% | ||

Implementation Strategy

Phased Approach

For companies new to progressive die technology, a phased implementation approach can mitigate risk. This might begin with simpler components before progressing to more complex parts.

Supplier Selection

Choosing the right equipment supplier and tooling partner is critical. Factors to consider include technical expertise, service support, and industry experience.

Workforce Development

Investing in employee training ensures that the organization can maximize the benefits of the new technology while maintaining safe operating practices.

Conclusion

Investing in a progressive die press represents a significant strategic decision with substantial financial implications. While the initial investment is considerable, the potential benefits in terms of increased productivity, reduced labor costs, improved quality, and enhanced competitiveness can deliver an attractive return on investment for suitable applications.

The viability of such an investment depends on multiple factors including production volumes, part complexity, labor costs, and market conditions. Companies should conduct a thorough cost-benefit analysis specific to their operations, considering both quantitative financial metrics and qualitative strategic factors.

For manufacturers with appropriate application volumes and technical capabilities, progressive die press technology can transform production efficiency and create sustainable competitive advantages in an increasingly challenging global marketplace.