Cost-Effective Ways to Upgrade Your Stamping Machine

Stamping machines are critical assets in manufacturing, but upgrading them doesn't always require a massive capital investment. By focusing on strategic, low-cost improvements, businesses can enhance performance, accuracy, and longevity without breaking the bank. This guide explores practical, budget-friendly upgrades that deliver significant returns.

1. Retrofit with Modern Control Systems

Older mechanical or basic electronic controls can limit your stamping machine's capabilities. Retrofitting with a modern PLC (Programmable Logic Controller) or CNC (Computer Numerical Control) system is a highly cost-effective upgrade. These systems improve precision, allow for easier programming, and enable automation features like automatic tool changes or speed adjustments.

A modern PLC control panel installed on a stamping machine, replacing outdated controls for improved precision and automation.

Benefits include reduced setup times, fewer errors, and the ability to store multiple job profiles. The initial investment is far lower than purchasing a new machine and can breathe new life into older equipment.

2. Upgrade Tooling and Dies

Worn or outdated tooling is a primary cause of poor stamping quality and machine strain. Investing in higher-quality, durable dies or implementing quick-change tooling systems can yield immediate improvements.

a) High-Speed Steel (HSS) or Carbide Tooling

While more expensive upfront than standard tool steel, HSS or carbide tools last significantly longer and maintain a sharper edge. This reduces downtime for tool changes and improves the quality of stamped parts, making it cost-effective in the long run.

b) Quick-Change Die Systems

These systems allow operators to change dies in minutes instead of hours. The reduction in downtime directly increases production capacity and operational efficiency.

| Material | Initial Cost | Lifespan | Best For |

|---|---|---|---|

| Standard Tool Steel | Low | Short | Low-volume, non-abrasive materials |

| High-Speed Steel (HSS) | Medium | Medium | General purpose, higher volume |

| Carbide | High | Long | High-volume, abrasive materials, high precision |

3. Enhance Lubrication Systems

Manual lubrication is inconsistent and can lead to premature wear. Upgrading to an automatic, centralized lubrication system ensures that critical components like slides, bearings, and guides receive the right amount of lubricant at the right time.

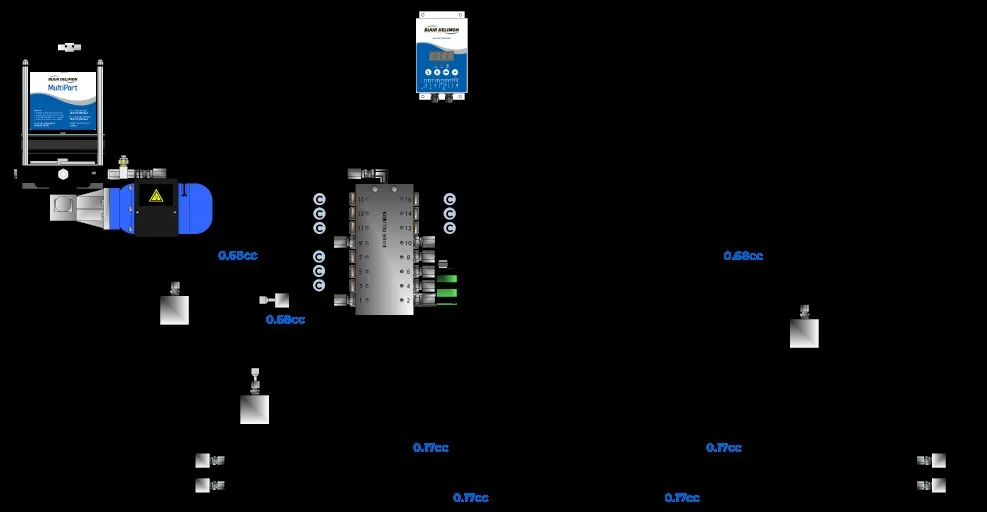

Diagram of an automatic lubrication system on a stamping press, showing lubricant lines connected to key moving parts.

This upgrade reduces friction, minimizes wear and tear, lowers operating temperatures, and extends the machine's service life. It also contributes to energy efficiency by reducing the power needed to overcome friction.

4. Implement Predictive Maintenance Sensors

Reactive maintenance is costly. Installing low-cost sensors to monitor machine health can prevent catastrophic failures. Key sensors include:

- Vibration Sensors: Detect misalignment or bearing wear.

- Temperature Sensors: Monitor overheating in motors or hydraulic systems.

- Acoustic Sensors: Listen for unusual noises indicating problems.

This data can be fed into a simple software dashboard, allowing maintenance teams to address issues before they cause downtime. This is a low-cost step towards a predictive maintenance strategy.

5. Improve Safety and Ergonomics

Safety upgrades are not just a regulatory requirement; they are a smart investment. Adding modern light curtains, two-hand controls, or ergonomic workstations can reduce the risk of accidents and operator fatigue.

A safer work environment leads to fewer injuries, lower insurance costs, and improved morale, which indirectly boosts productivity. These upgrades are often modular and can be installed without major machine modifications.

Safety light curtains installed around the point of operation on a stamping press, ensuring operator safety without impeding workflow.

6. Optimize Energy Consumption

Older stamping machines can be energy hogs. Simple upgrades can lead to substantial savings on electricity bills.

a) Variable Frequency Drives (VFDs)

Installing a VFD on the main motor allows it to run only at the speed required for the specific job, rather than at full power continuously. This significantly reduces energy consumption, especially during non-productive cycles.

b) LED Lighting

Replacing old fluorescent or incandescent lighting above the machine with bright, efficient LED lights improves visibility for operators and uses a fraction of the energy.

| Upgrade | Initial Investment | Estimated Annual Energy Saving | Payback Period |

|---|---|---|---|

| VFD Installation | $$$ | 15-30% | 1-2 years |

| Automatic Lubrication | $$ | 5-10% (via reduced friction) | 1-3 years |

| LED Lighting Retrofit | $ | 60-80% on lighting load | < 1 year |

Conclusion

A complete machine replacement is not the only path to improved performance. By strategically upgrading control systems, tooling, lubrication, maintenance protocols, safety features, and energy systems, manufacturers can achieve remarkable gains in productivity, quality, and cost-efficiency. A phased approach to these cost-effective upgrades allows for continuous improvement while managing budget constraints effectively.