Deep Drawing Power Press: Principles, Applications, and Advancements

The deep drawing power press stands as a cornerstone technology in the manufacturing and metalworking industries. This specialized machine tool is designed to transform flat sheet metal blanks into complex, hollow-shaped components through a process known as deep drawing. Unlike simple punching or blanking, deep drawing involves significant plastic deformation, where the material is drawn into a die cavity by a punch, resulting in seamless parts with high depth-to-diameter ratios. The power press provides the necessary force, control, and precision to execute this demanding operation efficiently and consistently, making it indispensable for producing a vast array of products, from automotive fuel tanks and kitchen sinks to aerospace components and electronic enclosures.

Fundamental Working Principle and Process

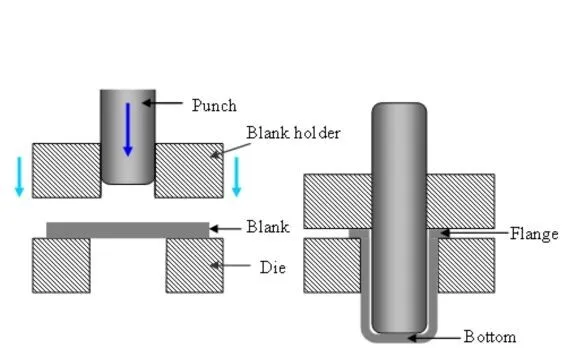

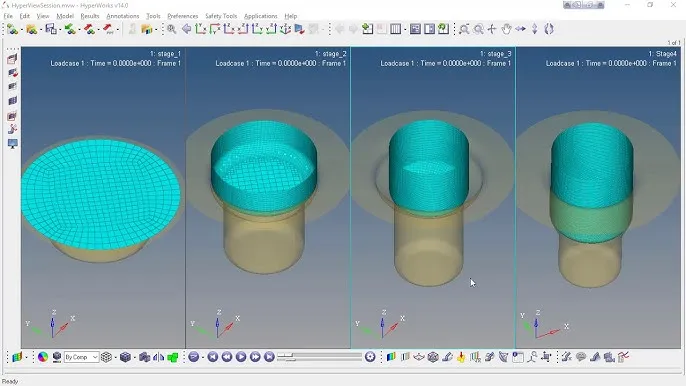

The deep drawing process on a power press is a sequence of carefully coordinated steps. It begins with a flat metal blank, typically circular, placed over a die opening. A punch, mounted on the moving ram (slide) of the press, then descends and forces the blank into the die cavity. A blank holder applies crucial pressure around the periphery of the blank to prevent wrinkling as the material flows radially inward. The success of the operation depends on the precise control of several factors, including the punch and die clearance, lubrication, blank holder force, and the mechanical properties of the sheet metal. The power press must deliver a smooth, controlled motion—often with a slow drawing speed—to facilitate proper material flow without causing tearing or excessive thinning, particularly at the corners of the drawn part.

Key Components of a Deep Drawing Power Press

A deep drawing power press is a robust assembly of critical components, each playing a vital role:

- Frame: The massive, rigid structure that absorbs the full tonnage of the press force. It is typically a C-frame or straight-side design, with straight-side presses offering better alignment for deep drawing applications.

- Ram (Slide): The vertically moving component that carries the punch. It is driven by the press's drive system.

- Drive System: The source of power and motion. This can be mechanical (using a crankshaft, eccentric gear, or knuckle joint), hydraulic, or servo-electric. Hydraulic presses are often preferred for deep drawing due to their ability to provide full tonnage throughout the stroke and adjustable speed profiles.

- Bed / Bolster Plate: The stationary table where the die assembly is mounted.

- Blank Holder (Pressure Pad): Often part of the die system, it is critical for applying the necessary blank holding force (BHF) to control material flow.

- Control System: Modern presses feature programmable logic controllers (PLCs) and touch-screen interfaces for setting parameters like stroke length, speed, and force.

Types of Deep Drawing Power Presses

The selection of a press type depends on production volume, part complexity, and required force profile. The main categories are:

| Press Type | Drive Mechanism | Key Characteristics | Typical Applications |

|---|---|---|---|

| Mechanical Press | Crankshaft, Eccentric, Knuckle Joint | High speed, fixed stroke, tonnage varies with stroke position. Knuckle joints provide very high force near bottom dead center. | High-volume production of simpler, shallower draws. |

| Hydraulic Press | Hydraulic Cylinders | Full tonnage throughout the stroke, adjustable stroke length and speed, programmable pressure profiles. Superior for complex, deep draws. | Medium to low volume, complex parts, prototyping, and materials with high forming resistance. |

| Servo-Electric Press | Servo Motor & Ball Screw | Precise control of slide motion and position, energy-efficient, programmable stroke profiles, quiet operation. | Precision drawing, advanced materials, and processes requiring exact motion control. |

Critical Process Parameters and Control

Optimizing a deep drawing operation requires meticulous attention to parameters. The blank holder force (BHF) is perhaps the most critical; too low leads to wrinkles, too high causes tearing. The punch and die radius affect material flow and thinning. Lubrication reduces friction between the blank, die, and holder. The press must control the drawing speed to balance productivity with material formability. Modern presses with CNC controls allow for the programming of multi-stage force and speed profiles, enabling the forming of challenging geometries and materials.

Industrial Applications and Material Considerations

Deep drawing power presses are ubiquitous across heavy and precision industries. In automotive manufacturing, they produce fuel tanks, oil pans, wheel covers, and structural body parts. The appliance industry relies on them for sinks, pots, pans, and washing machine tubs. In aerospace, they form housings and cowlings. The process works with a wide range of ductile metals, including:

- Low-Carbon Steel: The most common material due to its excellent formability and low cost.

- Stainless Steel: Used for corrosion-resistant parts but requires higher press forces.

- Aluminum and Alloys: Favored for lightweight parts; requires careful control to avoid tearing.

- Copper and Brass: Used for electrical components and decorative items.

Technological Advancements and Future Trends

The evolution of deep drawing power presses is driven by demands for greater precision, flexibility, and intelligence. The integration of servo-drive technology has been a game-changer, allowing for "smart" slide motion that can be tailored for each stage of the draw. IoT (Internet of Things) connectivity enables predictive maintenance by monitoring press health indicators like vibration, temperature, and force. Simulation software (FEA) is used upfront to predict forming issues and optimize die design and press parameters before physical trials, reducing setup time and material waste. The trend is towards more adaptive, data-driven presses that can self-correct and integrate seamlessly into automated, lights-out manufacturing cells.

Safety and Maintenance Imperatives

Given the immense forces involved, safety is paramount. Modern presses are equipped with light curtains, two-hand controls, and interlocked guards. Regular maintenance—including lubrication, alignment checks, and inspection of critical components like gears, brakes, and hydraulic systems—is essential to ensure consistent part quality, prolong press life, and prevent catastrophic failures. A well-maintained deep drawing press is a productive and safe asset on the factory floor.

In conclusion, the deep drawing power press remains a vital, dynamically evolving technology. From its fundamental mechanical principles to the integration of digital controls and simulation, it continues to enable the mass production of high-quality, complex metal parts that form the backbone of modern industrial society. Its continued advancement will be central to the future of efficient and innovative manufacturing.