In the realm of industrial manufacturing, few machines are as pivotal and versatile as the extrusion press. This formidable equipment is the cornerstone of shaping metals and plastics into complex, continuous profiles with remarkable efficiency and precision. From the aluminum frames of skyscrapers and vehicles to the plastic conduits that protect our wiring, extrusion presses play a silent yet indispensable role in building the modern world. This article delves into the principles, types, applications, and technological advancements of these powerful machines.

Fundamental Principles of Extrusion

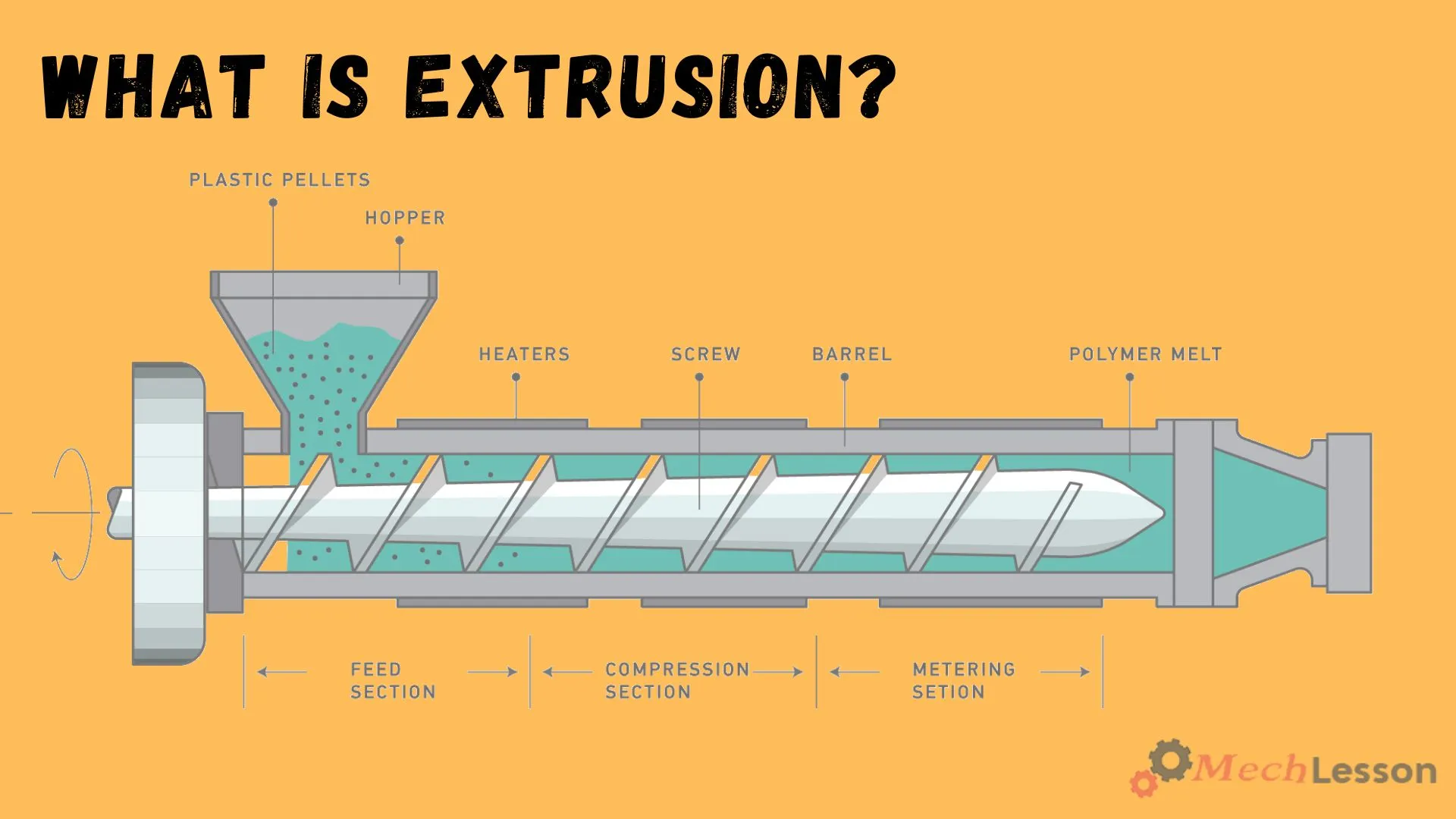

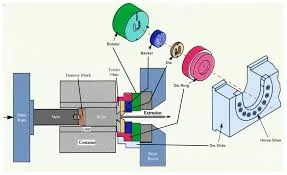

Extrusion is a process that forces material through a shaped orifice, known as a die, to create a long product with a fixed cross-sectional profile. The extrusion press provides the immense force required for this operation. The basic sequence involves loading a billet (a cylindrical block of material) into a container, applying pressure via a ram or stem, and pushing the material through the die. The resulting "extrudate" emerges as a continuous length, which is then cooled, straightened, and cut to specification.

Key Components of an Extrusion Press

An extrusion press is a complex assembly of several critical components:

- Main Cylinder & Ram: The heart of the press, generating the required extrusion force, which can range from a few hundred to over 25,000 tons.

- Container: Houses the billet and withstands extreme internal pressures during extrusion.

- Die & Die Stack: The tooling that defines the shape of the final product. It is mounted on a sturdy die slide or die carrier.

- Billet Loader & Heater: Automated systems that feed and preheat billets to a suitable plastic state for deformation.

- Run-Out Table & Handling System: Conveyors and pullers that support, cool, and transport the extruded product.

Types of Extrusion Presses

Extrusion presses are primarily classified by their drive mechanism and process direction.

1. Hydraulic Extrusion Presses

The most common type, using high-pressure hydraulic fluid to actuate the ram. They offer superior control over speed and pressure, making them ideal for a wide range of materials and complex profiles.

2. Mechanical Extrusion Presses

Utilize a motor-driven crank or toggle mechanism. They are generally faster and more energy-efficient for high-volume production of simpler shapes but offer less process flexibility than hydraulic presses.

3. By Process: Direct vs. Indirect Extrusion

Direct Extrusion: The ram pushes the billet directly through the die. This is the most common method, but higher friction between the billet and container requires more force.

Indirect Extrusion: The die is mounted on the ram, and the billet remains stationary relative to the container. This reduces friction and required force, improving efficiency and billet length use.

| Parameter | Direct Extrusion | Indirect Extrusion |

|---|---|---|

| Relative Motion | Billet moves relative to container | Die moves; billet stationary in container |

| Friction Force | High | Low to negligible |

| Required Force | Higher | Lower (by ~25-30%) |

| Billet Length | Limited by ram stability & friction | Can use longer billets |

| Common Applications | General purpose, rods, bars, solid profiles | High-precision tubes, hollow profiles |

Primary Applications and Materials

Extrusion presses are workhorses across multiple industries.

Aluminum and Non-Ferrous Metals

This is the largest application area. Presses produce architectural frames, automotive components (rails, heat sinks), aerospace structures, and electrical busbars. The table below outlines common aluminum products.

| Industry | Typical Extruded Products |

|---|---|

| Construction & Architecture | Window/door frames, curtain walls, roofing systems, bridges |

| Transportation | Chassis rails, body trim, heat exchangers, seat frames |

| Electrical | Conductor bars, heat sinks, cable ducts, LED lighting profiles |

| Industrial | Machine guards, conveyor tracks, hydraulic tubing |

Steel and Copper Alloys

Used for producing seamless tubes, solid rods, and specialized structural components under high temperatures and pressures.

Plastics and Polymers

While often called "extruders," the principle is similar. They produce piping, sheets, films, and insulated wire jacketing on a massive scale.

Technological Advancements and Trends

Modern extrusion presses are smarter, more efficient, and more precise than ever.

Automation and Industry 4.0

Integrated PLCs and IoT sensors enable real-time monitoring of pressure, temperature, and speed. Predictive maintenance algorithms minimize downtime.

Energy Efficiency

New designs incorporate variable-speed pump drives and energy recovery systems, drastically reducing the substantial power consumption of hydraulic presses.

Precision and Flexibility

Advanced die design software (CAD/CAM) and closed-loop control systems allow for rapid changeovers and production of highly intricate, tight-tolerance profiles.

Conclusion

Extrusion presses are fundamental to modern material shaping. Their ability to transform raw billets into endless, complex profiles with high structural integrity makes them irreplaceable in sectors demanding lightweight, strong, and customizable components. As technology advances, these presses continue to evolve, becoming more sustainable, automated, and capable, ensuring their central role in manufacturing for decades to come. From the simplest wire to the most advanced aerospace alloy, the mark of the extrusion press is everywhere.