High Speed Punch Press: Revolutionizing Modern Manufacturing

The high speed punch press represents one of the most significant advancements in modern manufacturing technology. These precision machines have revolutionized production processes across numerous industries, from automotive to electronics, by delivering unprecedented speed, accuracy, and efficiency in metal forming operations.

Fundamental Principles of High Speed Punch Press Operation

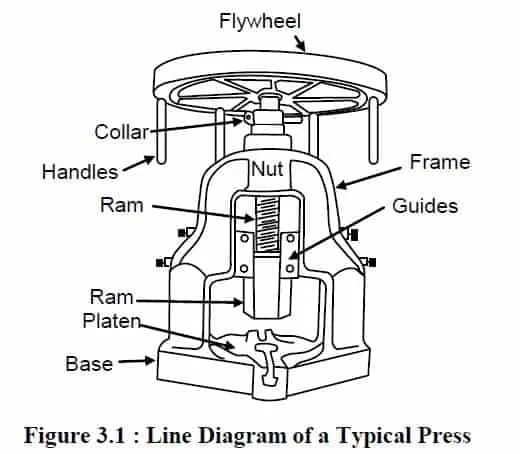

High speed punch presses operate on the fundamental principle of converting rotational motion into linear motion to deliver precise, rapid impacts on metal sheets. The core mechanism typically involves an eccentric shaft or crankshaft that drives the ram in a vertical motion, with sophisticated control systems managing the entire operation.

Modern high speed punch presses can achieve staggering operational speeds, with some models capable of performing up to 2,000 strokes per minute. This remarkable speed is made possible through advanced engineering, including precision-balanced components, high-performance servomotors, and sophisticated vibration-damping systems.

Key Components and Their Functions

Drive System

The drive system forms the heart of the high speed punch press, typically utilizing either mechanical or servo-driven mechanisms. Servo-driven presses offer superior control over ram motion, allowing for programmable stroke lengths and speeds that can be optimized for different materials and operations.

Control System

Advanced CNC (Computer Numerical Control) systems govern the operation of modern high speed punch presses. These systems provide precise control over every aspect of the punching process, including positioning, speed, and force application, ensuring consistent quality and repeatability.

Tooling and Die System

The tooling system in high speed punch presses is designed for rapid changeover and minimal downtime. Quick-change tool holders and standardized die sets enable manufacturers to switch between different punching operations in minutes rather than hours.

Performance Specifications and Capabilities

| Parameter | Standard Range | High-Performance Models | Applications |

|---|---|---|---|

| Stroke Rate | 200-800 SPM | 800-2,000 SPM | General to high-volume production |

| Tonnage Capacity | 20-100 tons | 100-300 tons | Light to heavy-gauge materials |

| Positioning Accuracy | ±0.1 mm | ±0.01 mm | Precision components |

| Material Thickness | 0.5-3.0 mm | 0.1-6.0 mm | Various material capabilities |

Applications Across Industries

Automotive Manufacturing

In the automotive industry, high speed punch presses are indispensable for producing body panels, chassis components, and various interior and exterior parts. The ability to maintain tight tolerances while operating at high speeds makes these machines essential for meeting the demanding production schedules of automotive manufacturers.

Electronics and Consumer Goods

The electronics industry relies heavily on high speed punch presses for manufacturing enclosures, heat sinks, connectors, and various internal components. The precision and speed of these machines are crucial for producing the intricate parts required in modern electronic devices.

Aerospace and Defense

In aerospace applications, high speed punch presses are used to create lightweight, high-strength components with exceptional dimensional accuracy. The ability to work with advanced materials like titanium and high-strength alloys makes these machines valuable in this demanding sector.

Advantages Over Conventional Punch Presses

| Feature | High Speed Punch Press | Conventional Punch Press | Benefit |

|---|---|---|---|

| Production Speed | 200-2,000 SPM | 40-150 SPM | 3-10x faster production |

| Energy Consumption | Optimized for efficiency | Higher per part | Reduced operating costs |

| Setup Time | 5-15 minutes | 30-90 minutes | Faster changeovers |

| Precision | ±0.01-0.1 mm | ±0.1-0.5 mm | Higher quality parts |

Technological Innovations and Future Trends

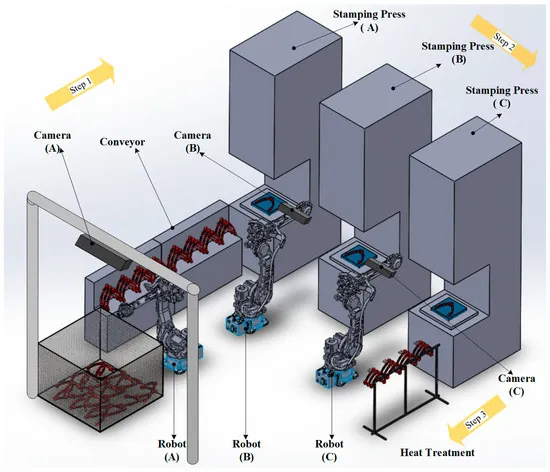

The evolution of high speed punch press technology continues with several emerging trends shaping the future of this equipment. Industry 4.0 integration, IoT connectivity, and artificial intelligence are transforming how these machines operate and are maintained.

Smart Manufacturing Integration

Modern high speed punch presses are increasingly equipped with sensors and connectivity features that enable real-time monitoring of performance parameters. This data-driven approach allows for predictive maintenance, reducing unplanned downtime and optimizing production schedules.

Advanced Material Compatibility

Recent advancements have expanded the range of materials that can be processed by high speed punch presses. From advanced high-strength steels to non-ferrous alloys and composite materials, these machines continue to adapt to the evolving needs of modern manufacturing.

Maintenance and Safety Considerations

Proper maintenance is crucial for ensuring the longevity and optimal performance of high speed punch presses. Regular inspection of critical components, lubrication systems, and safety mechanisms is essential for preventing breakdowns and ensuring operator safety.

Preventive Maintenance Schedule

Implementing a comprehensive preventive maintenance program is essential for maximizing equipment uptime and extending service life. This includes regular inspection of mechanical components, lubrication system checks, and verification of safety systems.

Safety Systems and Protocols

Modern high speed punch presses incorporate multiple safety features, including light curtains, two-hand controls, and emergency stop systems. These features, combined with proper operator training, ensure a safe working environment while maintaining high production rates.

Economic Considerations and ROI

The investment in high speed punch press technology must be evaluated based on both initial costs and long-term returns. While these machines represent significant capital expenditure, their productivity gains, reduced labor requirements, and improved material utilization often result in attractive return on investment timelines.

| Cost Factor | Initial Impact | Long-term Benefit | Considerations |

|---|---|---|---|

| Equipment Cost | High | Improved productivity | 3-5 year typical payback |

| Operating Costs | Moderate | Lower per-part cost | Energy efficiency gains |

| Labor Requirements | Training investment | Reduced manpower | Higher skill level needed |

| Maintenance | Regular schedule | Reduced downtime | Preventive approach essential |

Conclusion

High speed punch presses have fundamentally transformed manufacturing capabilities across multiple industries. Their combination of speed, precision, and reliability makes them indispensable in today's competitive manufacturing landscape. As technology continues to advance, these machines will undoubtedly incorporate even more sophisticated features, further enhancing their capabilities and expanding their applications in modern manufacturing.

The ongoing development of high speed punch press technology reflects the broader trends in manufacturing toward greater automation, connectivity, and efficiency. Companies that strategically implement and optimize these advanced manufacturing systems position themselves for success in an increasingly competitive global marketplace.