Hot Foil Stamping Machines for Paper: The Ultimate Guide

Hot foil stamping machines represent one of the most sophisticated and elegant finishing techniques in the paper processing industry. These specialized machines apply metallic or pigmented foil to paper surfaces using heat and pressure, creating stunning visual effects that elevate ordinary paper products to premium status. From luxury packaging to corporate stationery, hot foil stamping adds a touch of sophistication that digital printing alone cannot achieve.

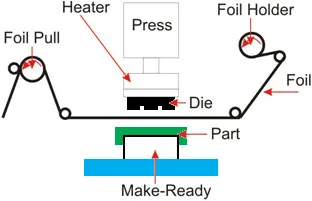

How Hot Foil Stamping Machines Work

The fundamental principle behind hot foil stamping involves three key elements: heat, pressure, and dwell time. The process begins with the creation of a metal die, typically made from brass, copper, or magnesium, which carries the design to be stamped. This die is heated and pressed against a thin foil film, transferring the foil's pigmented or metallic layer onto the paper substrate.

The machine's precision control systems regulate temperature, pressure, and timing to ensure consistent results across thousands of impressions. Modern hot foil stamping machines often incorporate computerized controls that allow operators to fine-tune these parameters for different paper types and foil materials.

Types of Hot Foil Stamping Machines for Paper

The market offers various types of hot foil stamping machines designed to meet different production needs and budget considerations. Understanding these variations is crucial for selecting the right equipment for specific applications.

Manual Hot Foil Stamping Machines

Manual machines represent the entry-level option in the hot foil stamping market. These units require operator intervention for each stamping cycle, making them ideal for low-volume production, prototyping, or small businesses with limited budgets. While slower than automated alternatives, manual machines offer excellent flexibility and are perfect for custom jobs or variable designs.

Semi-Automatic Hot Foil Stamping Machines

Semi-automatic machines strike a balance between manual operation and full automation. These systems typically feature automated foil advancement and some programmed functions while still requiring operator loading and unloading of materials. They represent an excellent middle ground for medium-volume production facilities looking to increase output without the substantial investment required for fully automated systems.

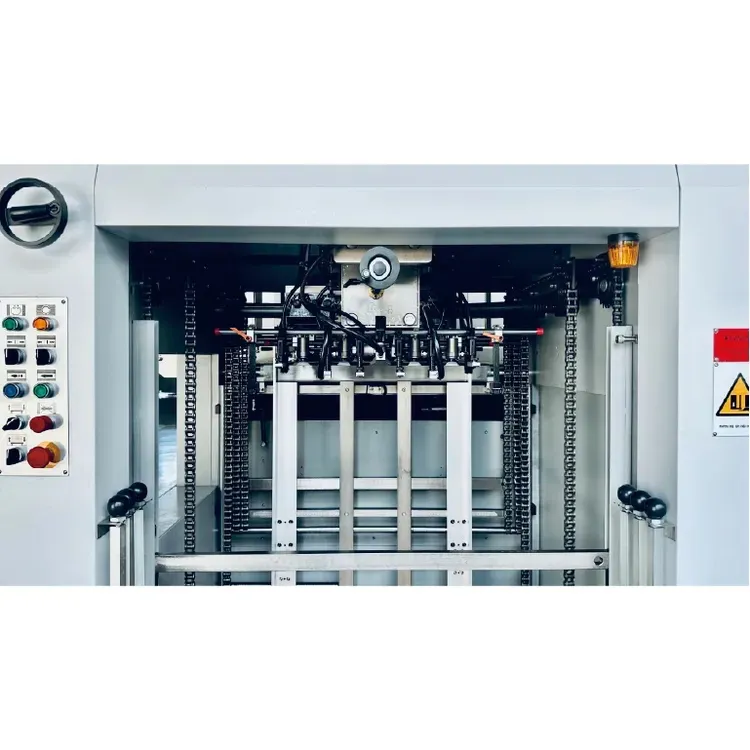

Fully Automatic Hot Foil Stamping Machines

For high-volume production environments, fully automatic hot foil stamping machines offer the highest efficiency and productivity. These sophisticated systems integrate with other printing and finishing equipment, creating seamless production lines that can process thousands of pieces per hour with minimal operator intervention. Advanced models feature robotic loading/unloading, vision systems for quality control, and sophisticated software for job management and changeovers.

Key Components of Hot Foil Stamping Machines

Understanding the critical components of hot foil stamping machines helps in making informed purchasing decisions and ensuring proper maintenance. The table below outlines the essential elements and their functions:

| Component | Function | Importance |

|---|---|---|

| Heating System | Heats the stamping die to activate the foil's adhesive layer | Critical for proper foil transfer and adhesion |

| Stamping Die | Carries the design to be stamped onto the paper | Determines the quality and precision of the stamped image |

| Foil Feeding System | Advances the foil roll between impressions | Ensures consistent foil positioning and minimizes waste |

| Pressure Mechanism | Applies controlled pressure during the stamping process | Affects foil adhesion and image sharpness |

| Control System | Regulates temperature, pressure, and timing parameters | Ensures consistency and repeatability across production runs |

Applications of Hot Foil Stamping on Paper

The versatility of hot foil stamping machines makes them suitable for numerous paper-based applications across various industries. The metallic and glossy finishes created through this process add perceived value and visual appeal to paper products.

Luxury Packaging

High-end product packaging for cosmetics, jewelry, electronics, and gourmet foods frequently incorporates hot foil stamping to create a premium unboxing experience. The reflective qualities of stamped metallic foils catch the consumer's eye and communicate quality before the product is even revealed.

Corporate Identity Materials

Business cards, letterheads, envelopes, and presentation folders with foil-stamped logos and text make powerful statements about a company's attention to detail and commitment to quality. The tactile experience of foil-stamped business cards often leads to higher retention rates among recipients.

Book Covers and Publishing

The publishing industry has long utilized hot foil stamping for creating elegant book covers, spine lettering, and special edition designs. Foil stamping adds durability to the cover design while providing a classic, sophisticated appearance that appeals to collectors and gift buyers.

Invitations and Stationery

Wedding invitations, anniversary announcements, and special event stationery frequently feature foil stamping to elevate the importance of the occasion. The process allows for intricate designs and personalization that digital printing cannot replicate.

Choosing the Right Hot Foil Stamping Machine

Selecting the appropriate hot foil stamping machine requires careful consideration of several factors, including production volume, material types, and budget constraints. The following table compares key selection criteria:

| Consideration | Manual Machines | Semi-Automatic Machines | Fully Automatic Machines |

|---|---|---|---|

| Production Speed | Up to 500 impressions/hour | 500-1,500 impressions/hour | 1,500-5,000+ impressions/hour |

| Operator Skill Required | Basic training | Moderate experience | Advanced technical skills |

| Initial Investment | $1,000 - $5,000 | $5,000 - $20,000 | $20,000 - $100,000+ |

| Best Suited For | Small businesses, prototyping | Medium-volume production | High-volume commercial printing |

Maintenance and Operational Best Practices

Proper maintenance of hot foil stamping machines ensures consistent performance, extends equipment lifespan, and maintains output quality. Regular cleaning of heating elements, inspection of electrical components, and lubrication of moving parts are essential maintenance tasks. Operators should also maintain detailed records of machine settings for different paper types and foil materials to streamline future production runs.

Future Trends in Hot Foil Stamping Technology

The hot foil stamping industry continues to evolve with technological advancements. Digital hot foil stamping, which eliminates the need for physical dies, is gaining traction for short runs and variable data applications. Integration with digital printing presses creates hybrid systems that combine the versatility of digital printing with the premium effects of foil stamping in a single pass. Additionally, environmentally friendly foil options and energy-efficient machines address growing sustainability concerns in the printing industry.

Conclusion

Hot foil stamping machines for paper represent a sophisticated finishing solution that adds significant value to paper products across numerous applications. Whether opting for manual, semi-automatic, or fully automated systems, businesses can leverage this technology to create distinctive, premium products that stand out in competitive markets. As technology advances, hot foil stamping continues to offer new possibilities for creative expression and brand differentiation on paper substrates.