How Transfer Press is Shaping the Future of Packaging

The packaging industry is undergoing a significant transformation, driven by technological advancements and changing consumer demands. Among the most impactful innovations shaping this evolution is transfer press technology, which is redefining manufacturing capabilities, sustainability standards, and design possibilities in packaging production.

The Fundamentals of Transfer Press Technology

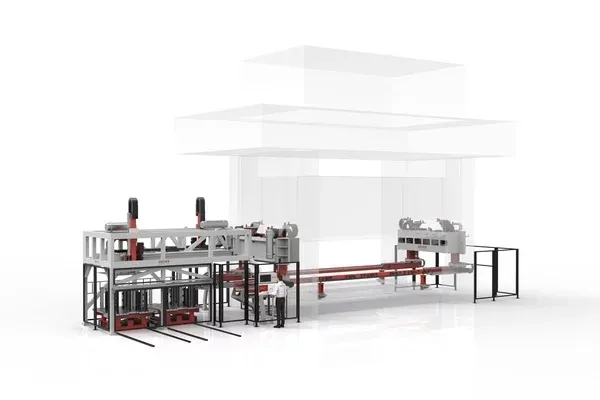

Transfer press technology represents a sophisticated approach to manufacturing that combines precision engineering with automated material handling. Unlike traditional single-station presses, transfer presses utilize a series of interconnected stations where materials are automatically transferred through various forming operations. This continuous process enables the creation of complex packaging components with unprecedented accuracy and efficiency.

The technology operates through a synchronized system where robotic arms or mechanical transfer mechanisms move workpieces between multiple press stations. Each station performs a specific operation - blanking, drawing, piercing, or forming - allowing for the creation of intricate packaging designs that would be impossible with conventional methods.

Key Advantages Driving Packaging Innovation

Enhanced Production Efficiency

Transfer press systems dramatically increase production speeds while maintaining consistent quality. The automated transfer between stations eliminates manual handling, reduces cycle times, and enables continuous operation. Modern transfer presses can achieve production rates of up to 80 strokes per minute, significantly outperforming traditional press methods.

Superior Material Utilization

One of the most significant benefits of transfer press technology is its exceptional material efficiency. The precision of transfer systems minimizes waste through optimized nesting and reduced scrap rates. This not only lowers production costs but also aligns with sustainable manufacturing principles by conserving resources.

Unmatched Design Flexibility

Transfer presses enable the production of complex, multi-feature packaging components in a single automated process. This capability allows designers to create innovative packaging solutions with integrated functionalities, enhanced structural integrity, and sophisticated aesthetic details that were previously unattainable.

Applications Across Packaging Segments

| Packaging Segment | Transfer Press Applications | Key Benefits |

|---|---|---|

| Food and Beverage | Can ends, container lids, specialty closures | Hygienic production, consistent seal quality, high-speed manufacturing |

| Cosmetics and Personal Care | Compacts, aerosol cans, luxury containers | Precision detailing, complex geometries, premium finish quality |

| Pharmaceutical | Medical device packaging, vial caps, diagnostic equipment | Sterile manufacturing, tight tolerances, regulatory compliance |

| Consumer Electronics | Battery housings, component enclosures, protective packaging | EMI shielding, structural integrity, customized solutions |

Sustainability and Environmental Impact

Transfer press technology contributes significantly to sustainable packaging initiatives through multiple channels. The precision manufacturing process reduces material waste by up to 40% compared to conventional methods. Additionally, the energy efficiency of modern transfer presses, combined with their ability to work with recycled materials, positions this technology as a cornerstone of eco-friendly packaging manufacturing.

Many manufacturers are leveraging transfer press capabilities to create lightweight packaging solutions that maintain structural integrity while reducing material consumption. This lightweight approach not only decreases raw material usage but also lowers transportation emissions throughout the supply chain.

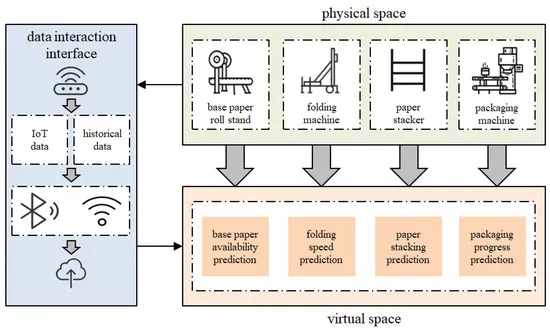

Technological Integration and Industry 4.0

The integration of transfer press systems with Industry 4.0 technologies is creating smart manufacturing environments for packaging production. Real-time monitoring systems, predictive maintenance algorithms, and data analytics platforms are being incorporated into transfer press operations, enabling:

- Predictive quality control and defect prevention

- Automated tool wear monitoring and maintenance scheduling

- Real-time production optimization based on performance data

- Seamless integration with supply chain management systems

Future Trends and Developments

Advanced Material Compatibility

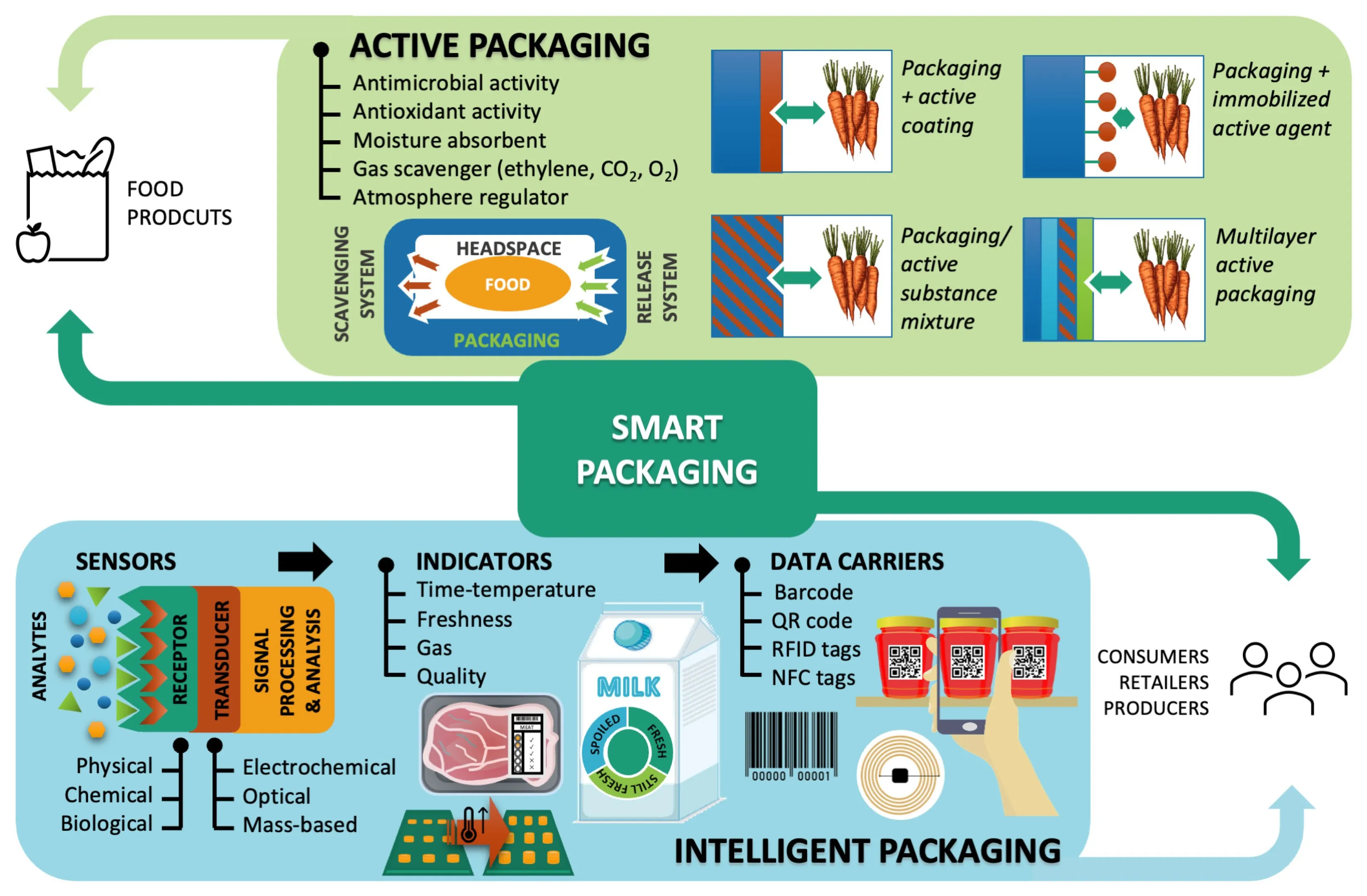

Future transfer press systems are being developed to handle an increasingly diverse range of materials, including advanced composites, biodegradable polymers, and smart materials with embedded functionality. This expansion will enable new packaging paradigms focused on sustainability, interactivity, and enhanced user experience.

Digital Twin Technology

The implementation of digital twin technology allows manufacturers to create virtual replicas of transfer press systems, enabling simulation, optimization, and troubleshooting without interrupting production. This approach significantly reduces development time for new packaging designs and improves overall system reliability.

Artificial Intelligence Integration

AI-powered transfer press systems are emerging that can autonomously optimize production parameters, predict maintenance needs, and adapt to varying material characteristics. These intelligent systems will further enhance efficiency, reduce downtime, and improve product quality consistency.

Economic Impact and Market Growth

The global adoption of transfer press technology in packaging manufacturing is driving significant economic benefits. According to industry analysis, the transfer press market for packaging applications is projected to grow at a compound annual growth rate of 6.8% through 2028. This growth is fueled by increasing demand for efficient, sustainable, and high-quality packaging solutions across multiple industries.

| Region | Market Share (2023) | Projected Growth (2024-2028) | Key Drivers |

|---|---|---|---|

| North America | 32% | 5.9% CAGR | Food packaging modernization, pharmaceutical expansion |

| Europe | 28% | 6.2% CAGR | Sustainability regulations, luxury goods packaging |

| Asia-Pacific | 35% | 8.1% CAGR | Manufacturing growth, consumer goods expansion |

| Rest of World | 5% | 7.3% CAGR | Industrial development, packaging infrastructure |

Conclusion: The Path Forward

Transfer press technology is fundamentally reshaping the packaging landscape by enabling unprecedented levels of efficiency, precision, and sustainability. As the technology continues to evolve through integration with digital systems and advanced materials, its impact on packaging design, manufacturing, and environmental performance will only intensify. Companies that embrace and invest in transfer press capabilities today are positioning themselves at the forefront of the packaging industry's future, ready to meet evolving consumer expectations and regulatory requirements while driving operational excellence and sustainable growth.

The ongoing innovation in transfer press technology promises to deliver even greater advancements in the coming years, solidifying its role as a cornerstone technology in the modern packaging ecosystem and a key enabler of the industry's sustainable transformation.