How to Maintain Your Hot Forging Press for Longevity

A hot forging press is a significant capital investment for any manufacturing operation. Its ability to shape metal at high temperatures makes it indispensable, but the extreme conditions also subject the machine to immense stress, wear, and tear. Proper maintenance is not just a recommendation; it is the single most critical factor in ensuring the longevity, reliability, and productivity of your forging press. A well-maintained press minimizes unplanned downtime, maintains consistent part quality, and protects your investment for decades. This guide outlines a comprehensive maintenance strategy to maximize the lifespan of your hot forging press.

1. The Foundation: Daily and Operational Checks

Long-term longevity is built on consistent daily habits. Before and during each shift, operators should perform a series of checks to catch minor issues before they escalate into major failures.

Visual Inspection

Conduct a thorough visual inspection of the entire press. Look for obvious signs of problems such as:

- Hydraulic Fluid Leaks: Check around cylinders, valves, pumps, and hose connections. Even small leaks can indicate failing seals and lead to system contamination or pressure loss.

- Structural Cracks or Damage: Inspect the frame, columns, and bolster plate for any signs of fatigue or cracking.

- Loose Components: Check for loose bolts, nuts, or guards. Vibration from forging operations can cause fasteners to work themselves loose over time.

Lubrication System Check

The lubrication system is the lifeblood of the press's moving parts. Verify that:

- Automatic lubricators are filled and functioning correctly.

- Manual lubrication points (zerk fittings) are greased according to the schedule.

- There are no blocked lubrication lines.

Inadequate lubrication is a primary cause of premature wear on guides, bearings, and the slide mechanism.

2. Proactive and Preventive Maintenance Schedule

Reactive maintenance (fixing things after they break) is costly and leads to extensive downtime. A proactive, scheduled maintenance program is essential.

| Frequency | Maintenance Task | Key Objectives |

|---|---|---|

| Daily | Visual inspection, check fluid levels, listen for unusual noises. | Identify immediate issues, ensure basic operational integrity. |

| Weekly | Check and clean filters, inspect electrical connections, verify clutch/brake operation. | Prevent contamination, ensure electrical safety and control accuracy. |

| Monthly | Test safety devices, inspect hydraulic hoses for wear, analyze hydraulic fluid sample. | Ensure operator safety, prevent catastrophic hose failure, monitor fluid condition. |

| Quarterly (Every 3-6 Months) | Change hydraulic and lubricant filters, thoroughly clean heat exchangers and cooling systems. | Maintain fluid cleanliness, prevent overheating, ensure efficient heat dissipation. |

| Annually | Comprehensive inspection by a certified technician. Check frame alignment, slide parallelism, and replace hydraulic fluid. | Assess long-term wear, ensure machine geometry is within tolerance, refresh critical fluids. |

Hydraulic System Maintenance

The hydraulic system is the powerhouse of the press. Key maintenance activities include:

- Fluid Analysis: Regularly sample the hydraulic fluid to check for viscosity breakdown, additive depletion, and contamination (water, metal particles). This predictive practice can warn you of impending pump or valve failures.

- Filter Replacement: Change filters as recommended by the manufacturer, not just when they are clogged. Clean fluid is crucial for the longevity of sensitive components like servo valves.

- Heat Management: Ensure cooling systems and heat exchangers are clean and functional. High fluid temperatures accelerate oxidation and degrade seals.

Mechanical Component Inspection

Focus on the components that endure the highest loads:

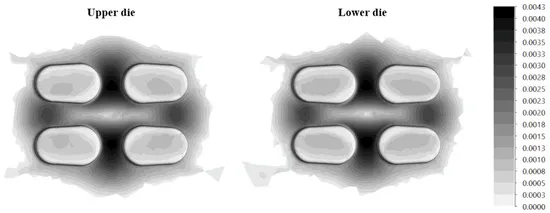

- Gibs and Guides: Check for wear and proper clearance. Excessive play can lead to misalignment and poor part quality.

- Bolster Plate and Die Holders: Inspect for flatness and cracks. Damage here can affect die life and part accuracy.

- Connecting Rods and Bearings: Look for signs of fatigue or abnormal wear during annual inspections.

3. Critical Considerations for Extreme Environments

Hot forging presses operate in some of the harshest industrial conditions. Maintenance must account for these factors.

Heat and Thermal Cycling

The radiant heat from the hot billets can damage electrical components, seals, and lubricants. Use high-temperature grease and heat shields to protect vulnerable areas. Allow the press to cool down properly after a production run to minimize thermal stress on the structure.

Contamination Control

Forging environments are dirty. Scale (iron oxide) from the hot billets is abrasive and can ingress into moving parts. Implement effective housekeeping practices to keep the press and surrounding area as clean as possible. Use protective boots on cylinders and wipers on guide rods to keep contaminants out.

4. Operator Training and Documentation

Maintenance is a team effort. Well-trained operators are your first line of defense.

- Training: Ensure operators know how to perform basic checks, recognize abnormal sounds or behaviors, and understand the importance of reporting issues immediately.

- Documentation: Maintain a detailed logbook for every maintenance action, no matter how small. This history is invaluable for diagnosing recurring problems and planning future maintenance.

- OEM Manuals: Always refer to the original equipment manufacturer's manuals for specific tolerances, lubrication specifications, and safety procedures.

Conclusion

Maximizing the longevity of your hot forging press is a continuous process that requires discipline, foresight, and a commitment to quality. By implementing a rigorous daily check routine, adhering to a proactive preventive maintenance schedule, addressing the challenges of the forging environment, and investing in operator training, you can ensure your press remains a productive and reliable asset for years to come. Remember, the cost of consistent maintenance is always far less than the cost of a major breakdown.