Hydraulic Bending Machine Repair: Comprehensive Guide

Introduction to Hydraulic Bending Machine Systems

Hydraulic bending machines are essential equipment in metal fabrication industries, providing precision and power for bending various metal materials. These complex machines combine hydraulic power with mechanical components to achieve accurate bending operations. Understanding their repair and maintenance requirements is crucial for maintaining optimal performance and extending equipment lifespan.

Common Hydraulic Bending Machine Problems

Hydraulic bending machines can experience various issues that affect their performance. Recognizing these problems early can prevent costly downtime and major repairs.

Hydraulic System Failures

The hydraulic system is the heart of the bending machine, and failures here can significantly impact operation. Common hydraulic issues include:

| Problem | Symptoms | Possible Causes |

|---|---|---|

| Hydraulic Leaks | Oil puddles, reduced pressure | Worn seals, loose fittings, cracked hoses |

| Pressure Loss | Insufficient bending force | Faulty pump, relief valve issues, internal leaks |

| Overheating | Hot hydraulic oil, reduced efficiency | Clogged cooler, excessive operation, wrong oil viscosity |

| Noisy Operation | Unusual sounds from hydraulic system | Cavitation, air in system, worn pump components |

Mechanical Component Issues

Mechanical problems often involve wear and tear on moving parts and structural components:

- Worn tooling and dies affecting bend accuracy

- Misaligned ram or bed causing uneven bending

- Worn guide ways and gibs leading to play in movement

- Damaged ball screws or lead screws affecting positioning

Step-by-Step Repair Procedures

Proper repair procedures ensure safe and effective restoration of hydraulic bending machine functionality.

Safety Precautions

Hydraulic System Repair Steps

When addressing hydraulic system issues, follow these systematic steps:

| Step | Procedure | Tools Required |

|---|---|---|

| 1 | System depressurization and oil drainage | Drain pan, wrenches |

| 2 | Component inspection and diagnosis | Pressure gauge, multimeter |

| 3 | Seal and gasket replacement | Seal kit, cleaning solvent |

| 4 | Pump and valve servicing | Specialized tools, test equipment |

| 5 | System reassembly and testing | Torque wrench, pressure tester |

Mechanical Alignment Procedures

Proper mechanical alignment is critical for bending accuracy:

- Clean all guide ways and sliding surfaces

- Check ram parallelism using precision levels

- Adjust gibs to eliminate play while maintaining smooth movement

- Verify bed and ram alignment with dial indicators

- Test with sample bends and measure results

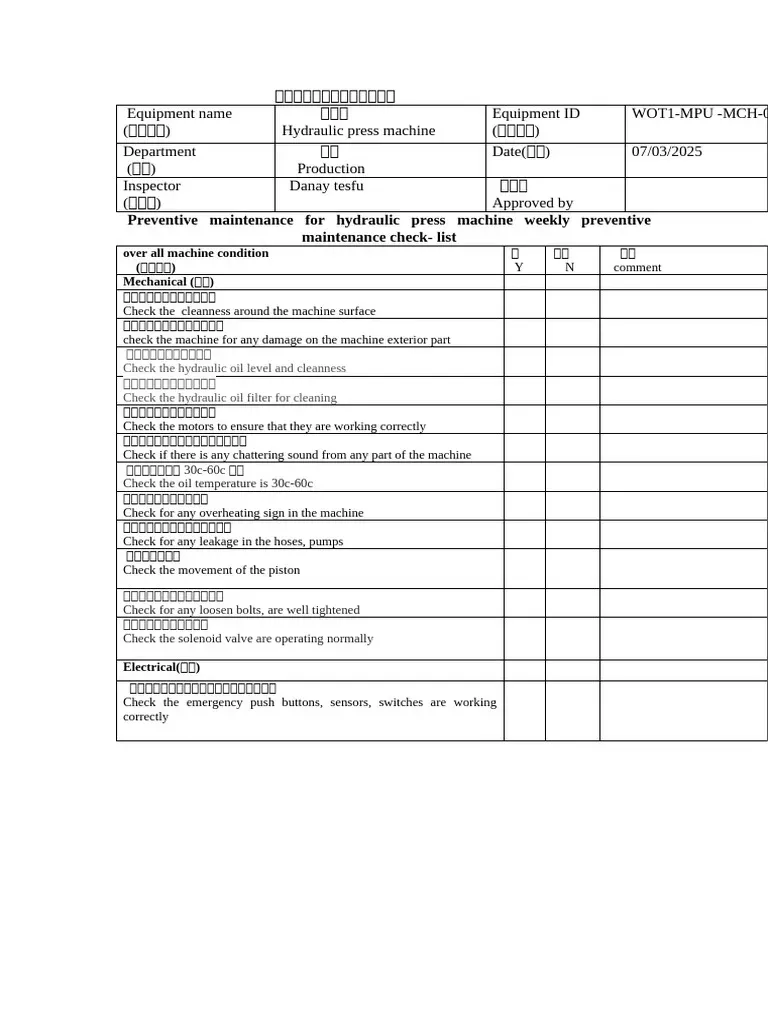

Preventive Maintenance Schedule

Implementing a regular maintenance schedule can prevent many common problems and extend machine life.

| Maintenance Task | Frequency | Key Activities |

|---|---|---|

| Daily Checks | Each shift | Visual inspection, check for leaks, verify safety devices |

| Weekly Maintenance | Weekly | Lubrication, hydraulic oil level check, clean filters |

| Monthly Service | Monthly | Comprehensive inspection, test all functions, check alignment |

| Quarterly Overhaul | Every 3 months | Hydraulic oil analysis, component wear inspection, system calibration |

| Annual Maintenance | Yearly | Complete system overhaul, replacement of worn components, full recalibration |

Troubleshooting Common Issues

Effective troubleshooting requires systematic analysis of symptoms and potential causes.

Bending Accuracy Problems

When bends are not accurate, consider these potential causes:

- Tooling wear or damage

- Hydraulic pressure fluctuations

- Mechanical misalignment

- Control system calibration errors

- Material variations

Performance Comparison: Before and After Repair

| Performance Metric | Before Repair | After Repair | Improvement |

|---|---|---|---|

| Bending Accuracy | ±1.5° | ±0.2° | 86% |

| Cycle Time | 45 seconds | 38 seconds | 16% |

| Hydraulic Pressure Stability | ±50 bar | ±10 bar | 80% |

| Energy Consumption | 15 kW/h | 12 kW/h | 20% |

Advanced Repair Techniques

For complex issues, advanced repair techniques may be necessary:

CNC System Diagnostics

Modern hydraulic bending machines often include CNC controls that require specialized diagnostic approaches:

- Software parameter backup and restoration

- Servo motor and encoder calibration

- Backlash compensation adjustment

- Positioning system recalibration

Structural Repair Methods

When frame or structural components are damaged:

- Magnetic particle inspection for crack detection

- Precision welding techniques for frame repair

- Stress relieving procedures

- Post-repair alignment verification

Conclusion

Proper hydraulic bending machine repair requires comprehensive knowledge of hydraulic systems, mechanical components, and control systems. By following systematic repair procedures, implementing regular maintenance schedules, and using proper troubleshooting techniques, manufacturers can maintain optimal machine performance, reduce downtime, and extend equipment lifespan. Always prioritize safety and consider professional assistance for complex repairs beyond your technical capabilities.