Innovations in Transfer Press for Faster Production

The manufacturing industry is constantly evolving, with a relentless pursuit of efficiency, precision, and speed. At the heart of many high-volume production lines, particularly in automotive, aerospace, and appliance manufacturing, stands the transfer press. This sophisticated machinery has undergone significant transformations, moving from purely mechanical workhorses to highly intelligent, automated systems. Recent innovations in transfer press technology are fundamentally reshaping production floors, enabling unprecedented levels of speed, accuracy, and flexibility. This article explores the key advancements that are making transfer presses faster and more productive than ever before.

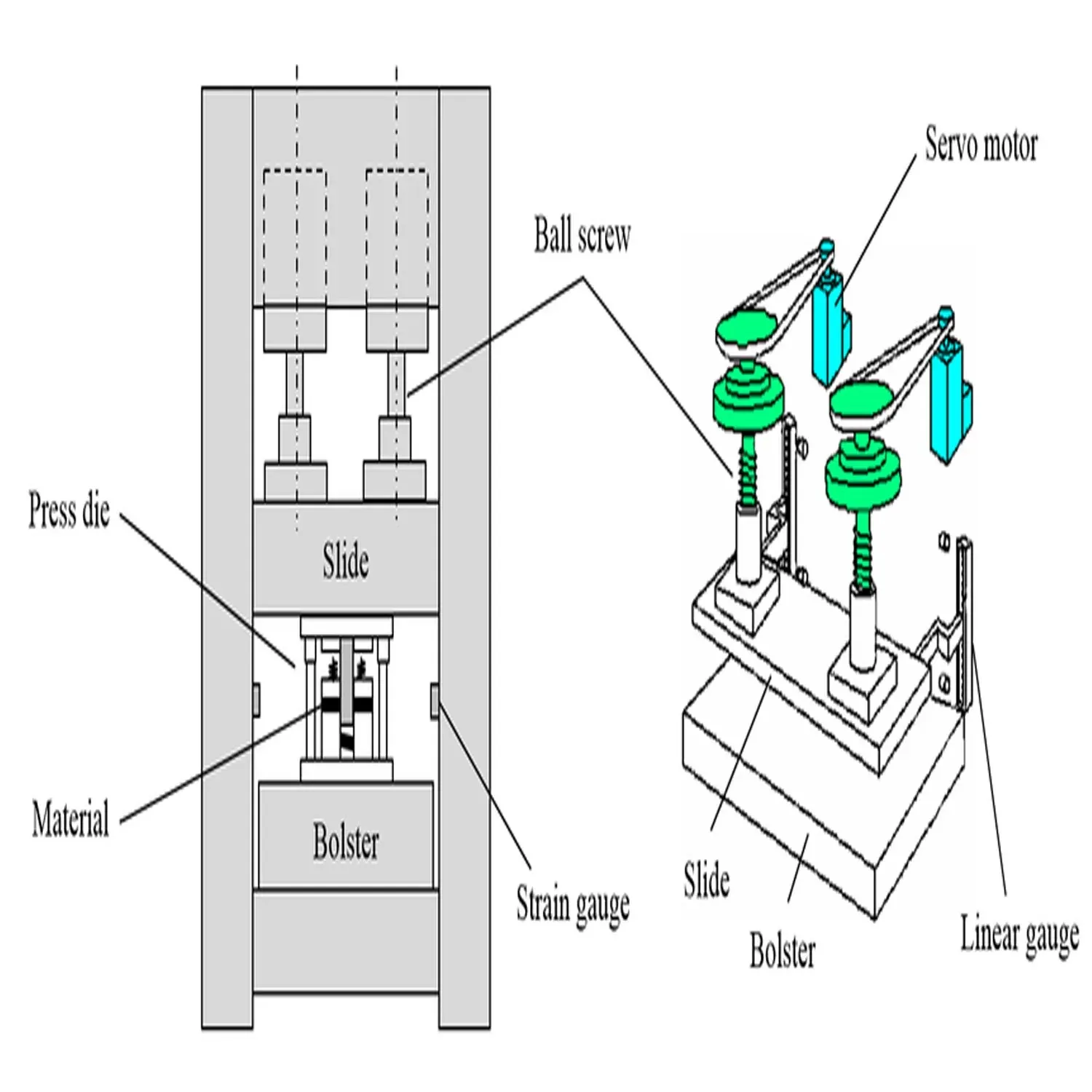

Advanced Drive Systems and Motion Control

The core of any press is its drive system, and this is where some of the most impactful innovations have occurred. Traditional mechanical presses often relied on single, large motors connected through complex gear trains. Modern innovations have introduced:

- Servo-Driven Technology: The adoption of servo motors has been a game-changer. Unlike traditional constant-speed motors, servos provide programmable control over the ram's motion profile. Operators can now customize the slide motion—adjusting speed, dwell time, and stroke—to optimize the forming process for each specific part. This allows for slower, more precise movements during the actual forming stage and much faster return strokes, significantly reducing cycle times without sacrificing quality.

- Direct Drive Systems: Eliminating gears and flywheels reduces mechanical complexity, inertia, and energy loss. Direct servo drives connected to the eccentric shaft provide more efficient power transfer, quicker response times, and higher accuracy in slide positioning, all contributing to faster overall operation.

Enhanced Automation and Robotics Integration

Speed in a transfer press isn't just about how fast the ram moves; it's about the seamless coordination of the entire production cell. Automation is the critical link.

- Intelligent Transfer Feeds: Modern transfer systems feature independent, servo-driven feed fingers. Each finger can be programmed with its own motion path, allowing for optimal positioning and reduced transfer time between stations. This eliminates the mechanical limitations of traditional, cam-driven transfer systems.

- Integrated Robotic Loading/Unloading: The front and rear ends of the press line have seen massive improvements. High-speed robots are now commonly integrated to load blanks and unload finished parts with incredible speed and precision. These robots often feature advanced vision systems to ensure correct part placement, further reducing misfeed errors and downtime.

-

In-Line Quality Control:

Vision systems and laser scanners can be installed within the press or immediately after it to perform 100% inspection of critical dimensions. This allows for real-time feedback and adjustment, preventing the production of large batches of defective parts. Automated Die Change Robotic carts and automated clamping systems can change massive die sets in minutes instead of hours, dramatically increasing press availability for production. Smart Presses: IoT and Data Analytics

The modern transfer press is not just a machine; it's a data hub. The integration of Industry 4.0 principles has given rise to the "smart press."

- Real-Time Monitoring Sensors: A network of sensors continuously monitors key parameters such as tonnage, slide position, vibration, temperature, and energy consumption. This data is streamed to a central control system.

- Predictive Maintenance: By analyzing trends in vibration and tonnage data, AI-powered algorithms can predict component failures (e.g., bearing wear) long before they cause unplanned downtime. Maintenance can be scheduled during planned stops, maximizing production uptime.

- Process Optimization: Data analytics can identify subtle inefficiencies in the production process, suggesting adjustments to motion profiles or transfer timing to shave precious seconds off the cycle time. This continuous, data-driven improvement is key to achieving maximum speed.

Conclusion

The innovations in transfer press technology represent a holistic leap forward. It is no longer just about applying more force faster; it is about the intelligent integration of advanced drives, precision automation, sophisticated tooling, and data-driven decision-making. These innovations work in concert to achieve a primary goal: faster production without compromising on safety, quality, or flexibility. As servo technology becomes more powerful, AI and IoT more deeply embedded, and new materials adopted, the transfer press will continue to evolve, remaining an indispensable asset for high-volume manufacturing in the 21st century and beyond.