Key Advantages of Using a Hot Forging Press

Hot forging presses are indispensable in the metalworking industry, enabling the shaping of metal parts through the application of heat and pressure. This process involves heating metal above its recrystallization temperature, typically between 950°C and 1250°C for steel, and then deforming it using a press to achieve the desired shape. The advantages of using a hot forging press are numerous, impacting product quality, production efficiency, and economic viability. This article explores the core benefits that make hot forging presses a preferred choice for manufacturers worldwide.

Enhanced Material Properties and Superior Strength

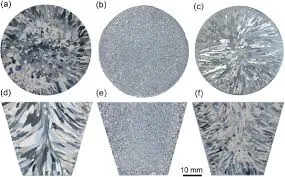

One of the most significant advantages of hot forging is the improvement in the mechanical properties of the metal. The process refines the grain structure of the material, eliminating voids and porosity that can weaken the part. As the metal is deformed above its recrystallization temperature, new, finer grains form, resulting in a uniform and continuous grain flow that follows the contour of the forged shape. This leads to exceptional strength, toughness, and fatigue resistance, making hot-forged components ideal for critical applications in aerospace, automotive, and heavy machinery.

Grain Flow and Structural Integrity

The directional grain flow achieved in hot forging is unattainable with machining or casting. This flow lines the metal's internal structure along the stress paths the part will encounter in service, dramatically enhancing its durability and resistance to impact and fatigue failure.

High Production Efficiency and Cost-Effectiveness

Hot forging presses, especially in automated lines, offer remarkable production rates. The ability to shape complex parts in a single or few strokes reduces machining time and material waste significantly. While the initial investment in a forging press and dies is substantial, the per-part cost drops dramatically at high volumes due to reduced labor, energy efficiency in mass production, and minimal material loss.

| Advantage | Impact on Production | Economic Benefit |

|---|---|---|

| High Speed & Automation | Can produce hundreds of parts per hour | Lower labor cost per unit |

| Near-Net Shape Forming | Minimizes subsequent machining operations | Reduces machining time and tool wear costs |

| Material Utilization | Very little material is wasted as scrap | Lower raw material costs per part |

| Die Longevity | Hot forging dies can withstand thousands of cycles | Reduces tooling and maintenance costs |

Reduction in Machining and Secondary Operations

By producing parts very close to their final dimensions (near-net shape), hot forging drastically reduces the need for expensive and time-consuming machining. This not only saves on equipment and labor but also preserves the beneficial grain flow, which would be cut if the part were heavily machined from bar stock.

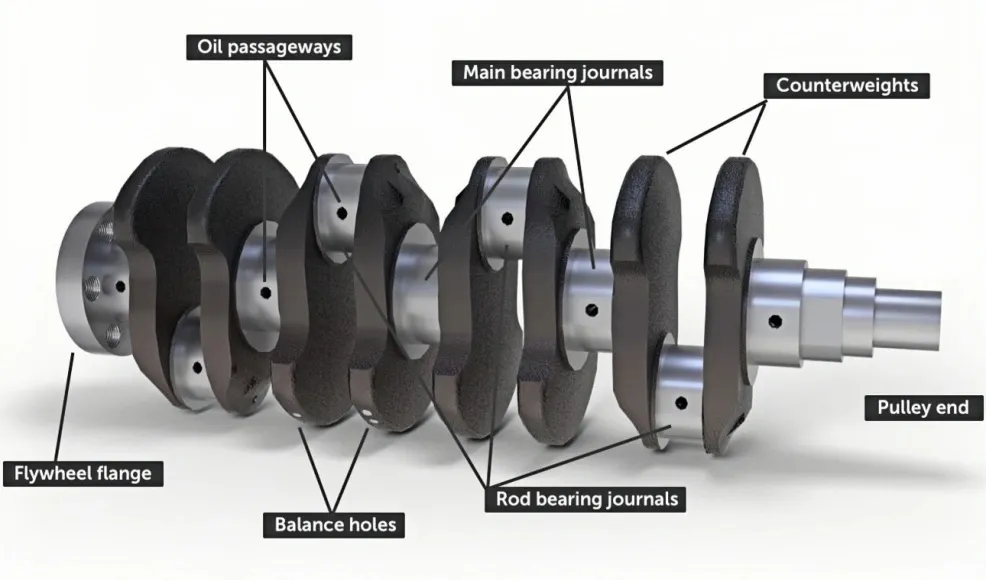

Ability to Forge Complex and Large Components

Hot forging presses, particularly large hydraulic and mechanical presses, possess the immense force required to deform tough metals into intricate shapes. The increased plasticity of heated metal allows for more severe deformation and the creation of complex geometries that would be impossible or prohibitively expensive with cold forging or machining. This capability is crucial for manufacturing large components like crankshafts, turbine blades, and structural parts for industrial equipment.

Versatility with a Wide Range of Materials

Hot forging is not limited to simple steels. The process is highly effective for a vast array of metals and alloys, including stainless steel, titanium, aluminum, brass, and high-temperature alloys. This versatility allows manufacturers to select the optimal material for the part's function—whether it requires high strength-to-weight ratio, corrosion resistance, or performance in extreme temperatures—and still benefit from the forging process's advantages.

Improved Safety and Working Conditions

Modern hot forging presses are designed with advanced safety features, including automated material handling, protective guards, and computerized controls that minimize operator exposure to heat and moving parts. This creates a safer working environment compared to older, more manual forging methods.

Summary

The adoption of hot forging press technology provides a compelling combination of superior part strength, high-volume production efficiency, material savings, and design flexibility. From enhancing the critical performance of metal components to offering long-term cost savings in mass production, the hot forging press remains a cornerstone of advanced manufacturing, enabling the creation of reliable and durable parts that form the backbone of modern industry.