Large Hydraulic Press: Powering Modern Industry

The large hydraulic press stands as one of the most critical and powerful pieces of equipment in heavy manufacturing and metalworking industries. Capable of exerting immense force—often ranging from hundreds to tens of thousands of tons—these presses shape the backbone of sectors like aerospace, automotive, energy, and defense. Their ability to plastically deform solid metal billets into precise, high-strength components makes them indispensable for producing parts where integrity and durability are paramount.

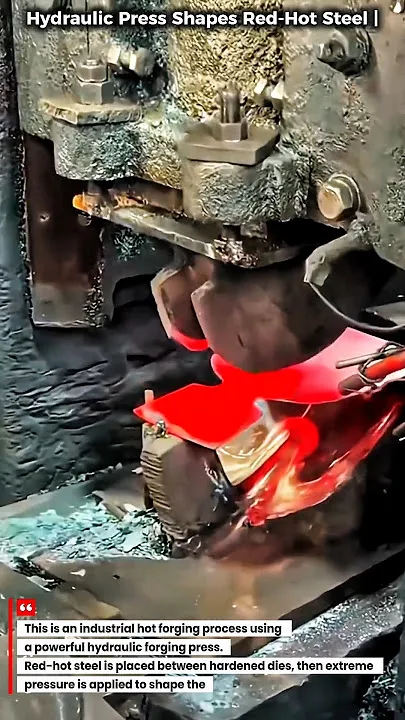

Figure 1: A large hydraulic press performing a hot forging operation on a significant metal workpiece.

Fundamental Working Principle

The operation of a large hydraulic press is governed by Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished in every direction. In practice, a small force applied to a small-area piston (the pump) creates a pressure in the hydraulic fluid. This pressure is then transmitted to a large-area piston (the ram or cylinder), resulting in a magnified output force.

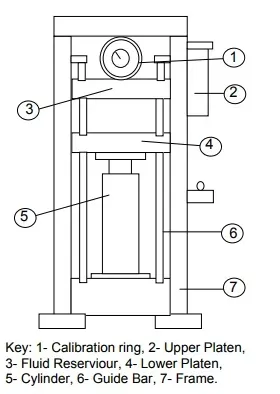

Key Components of a Large Hydraulic Press

- Frame: The robust structure, often a welded steel construction or prestressed frame, that withstands the full press force without deformation.

- Main Hydraulic Cylinder: The large-diameter cylinder that houses the main ram. It is the primary source of the pressing force.

- Ram/Platen: The moving component attached to the cylinder that directly applies force to the workpiece.

- Hydraulic Power Unit (HPU): Comprises pumps, motors, accumulators, valves, and reservoirs to generate and control high-pressure fluid flow.

- Control System: Modern presses use programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for precise control of force, speed, and position.

- Bolster Plate & Dies: The stationary table (bolster) and the tooling (dies) that hold and shape the workpiece.

Figure 2: Schematic diagram illustrating the core components of a standard hydraulic press system.

Major Types of Large Hydraulic Presses

Large hydraulic presses are categorized based on their frame design and application focus.

| Press Type | Frame Design | Typical Force Range | Primary Applications | Advantages |

|---|---|---|---|---|

| Four-Column (C-Frame) | Single, C-shaped arm | Up to 2,000 tons | Straightening, bending, medium forging | Good accessibility from three sides |

| Four-Column Press | Four vertical columns guiding a moving platen | 1,000 - 80,000+ tons | Forging, molding, deep drawing, laminating | Excellent rigidity, precision, and load distribution |

| Horizontal Forging Press | Horizontal cylinder and ram assembly | 500 - 15,000 tons | Extrusion, piercing, pipe testing | Facilitates handling of long workpieces |

| Custom Forging Press | Massive, often prestressed concrete/steel | 10,000 - 80,000 tons | Open-die forging of aerospace, energy components | Unmatched force for the largest components |

Critical Industrial Applications

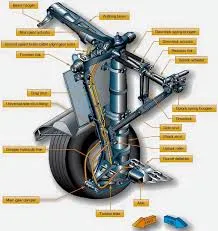

Aerospace and Aviation

Large hydraulic presses are used to forge critical structural components such as turbine discs, landing gear parts, wing spars, and fuselage frames from high-performance alloys like titanium and nickel-based superalloys. The isothermal forging process, performed on specialized hydraulic presses, is essential for creating complex, near-net-shape aerospace parts.

Figure 3: Forging a high-strength titanium component for aerospace applications using a large hydraulic press.

Automotive Manufacturing

In the automotive sector, these presses form body panels, chassis components, engine blocks, and transmission parts through deep drawing and stamping processes. Tandem press lines, consisting of multiple large hydraulic or mechanical presses, produce car body shells with high speed and precision.

Energy Sector

The production of large components for the energy industry relies heavily on massive forging presses. This includes forging reactor pressure vessels for nuclear plants, shafts and discs for steam and gas turbines in power generation, and large valves and flanges for oil and gas pipelines.

Sheet Metal Forming and Stamping

Hydraulic presses provide superior control in deep drawing operations for creating complex sheet metal parts, such as sinks, automotive fuel tanks, and appliance housings. Their ability to maintain full tonnage throughout the stroke is a key advantage over mechanical presses.

Advantages and Technological Evolution

The dominance of large hydraulic presses stems from their distinct advantages: infinitely variable force and speed control, the ability to deliver full rated force at any point in the stroke, overload protection, and remarkable versatility. Modern advancements include:

- Digital Control & Automation: Integration with robotics for automated feeding and part handling, and sophisticated CNC controls for repeatability.

- Energy Efficiency: New systems using variable-speed pump drives and energy recovery circuits significantly reduce power consumption.

- Smart Monitoring: IoT sensors and predictive maintenance software monitor cylinder pressure, temperature, alignment, and vibration to prevent failures.

- Hybrid Systems: Combining hydraulic power with electric drive mechanisms for faster cycle times and improved accuracy.

Conclusion

From forging the critical components that enable flight and generate power to stamping the vehicles we drive, the large hydraulic press remains an irreplaceable pillar of industrial capability. Its evolution from a brute-force tool to a digitally controlled, precision manufacturing center mirrors the advancement of modern industry itself. As materials become stronger and components more complex, the role of these powerful machines will only grow in importance, continuing to shape the physical world with unparalleled force and control.