Powder Compacting Press Machine: Comprehensive Guide

Powder compacting press machines represent one of the most significant advancements in modern manufacturing technology. These sophisticated machines have transformed how industries produce complex components with high precision and efficiency. From automotive parts to medical devices, powder compacting technology has become indispensable across numerous sectors.

Fundamental Principles of Powder Compaction

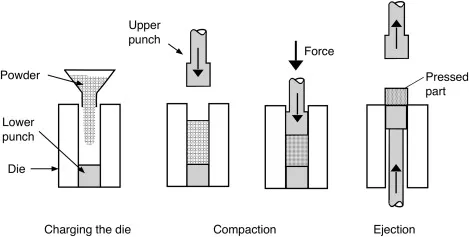

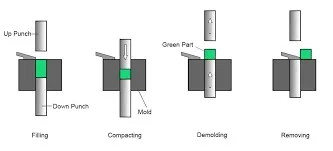

Powder compaction is a manufacturing process where powdered materials are compressed into specific shapes and densities using controlled pressure. The process involves filling a die cavity with precise amounts of powder and applying significant force to create a compacted part, known as a "green compact." This green compact then undergoes sintering to achieve its final mechanical properties.

Key Components of Powder Compacting Press Machines

Modern powder compacting presses consist of several critical components that work in harmony to achieve precise compaction:

- Hydraulic or Mechanical Drive System: Provides the necessary force for compaction

- Die Set Assembly: Determines the final shape of the compacted part

- Powder Feeding System: Ensures accurate powder distribution

- Control System: Manages pressure, speed, and timing parameters

- Ejection Mechanism: Safely removes the compacted part from the die

Types of Powder Compacting Press Machines

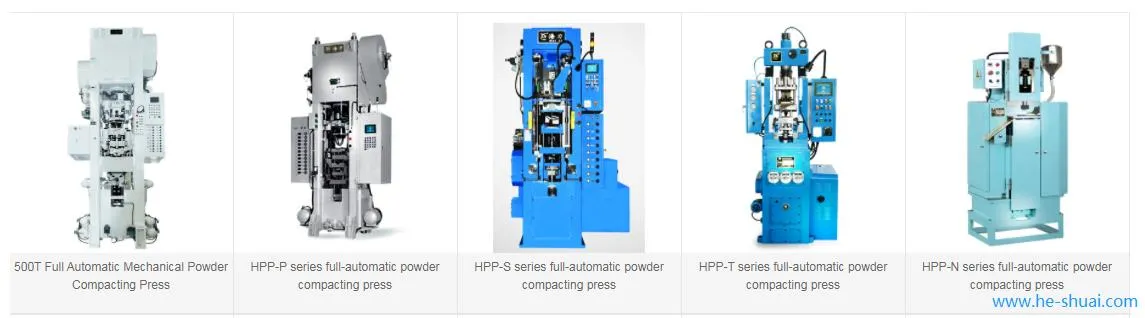

The industry utilizes various types of powder compacting presses, each designed for specific applications and production requirements.

Mechanical Presses

Mechanical presses use eccentric or crank mechanisms to generate compaction force. They are known for their high speed and consistent performance, making them ideal for mass production of standardized components.

Hydraulic Presses

Hydraulic presses utilize fluid power to generate compaction force, offering greater flexibility in pressure control and stroke length. These machines excel in producing complex geometries and handling varied material types.

Servo-Electric Presses

The latest innovation in compaction technology, servo-electric presses combine precision control with energy efficiency. They provide programmable motion profiles and real-time monitoring capabilities.

Technical Specifications and Performance Parameters

| Parameter | Mechanical Press | Hydraulic Press | Servo-Electric Press |

|---|---|---|---|

| Maximum Pressure Range | 50-1000 tons | 10-3000 tons | 5-500 tons |

| Production Speed | High (up to 100 parts/min) | Medium (20-60 parts/min) | Variable (10-80 parts/min) |

| Energy Efficiency | Medium | Low to Medium | High |

| Control Precision | Good | Very Good | Excellent |

| Initial Investment | Medium | High | Highest |

Applications Across Industries

Powder compacting press machines serve diverse industrial sectors with their versatile capabilities.

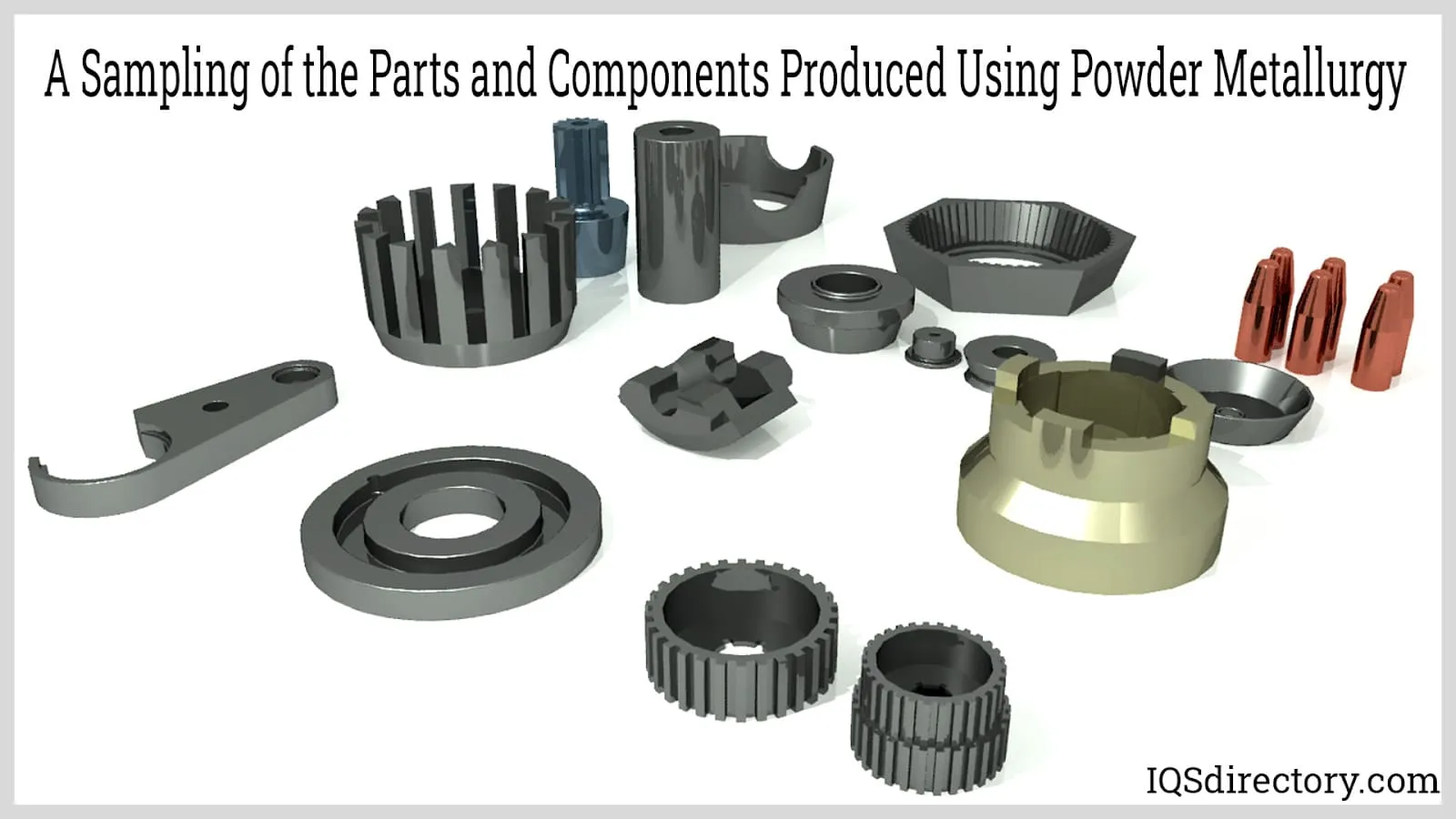

Automotive Industry

The automotive sector extensively uses powder metallurgy for producing gears, bearings, and engine components. The ability to create near-net-shape parts reduces material waste and machining requirements.

Medical and Dental

Medical implants, surgical instruments, and dental components benefit from the high precision and biocompatibility offered by powder compaction technology.

Electronics and Electrical

Magnetic components, electrical contacts, and heat sinks are commonly produced using powder compacting processes due to their excellent electrical and thermal properties.

Advantages of Powder Compacting Technology

The widespread adoption of powder compacting press machines is driven by numerous technical and economic benefits:

- Material Efficiency: Minimal material waste compared to traditional machining

- Complex Geometries: Ability to produce intricate shapes in single operations

- Consistent Quality: High repeatability and dimensional accuracy

- Cost Effectiveness: Reduced labor and energy costs per part

- Material Versatility: Compatible with metals, ceramics, and composite materials

Recent Technological Advancements

The field of powder compacting continues to evolve with several notable innovations:

Intelligent Control Systems

Modern presses incorporate AI and machine learning algorithms to optimize process parameters in real-time, ensuring consistent quality and predicting maintenance needs.

Multi-Level Compaction

Advanced machines now feature multi-level compaction capabilities, allowing for complex parts with varying densities and material properties within a single component.

Integrated Quality Monitoring

Real-time monitoring systems track key parameters such as density distribution, crack detection, and dimensional accuracy during the compaction process.

Future Trends and Developments

The future of powder compacting technology points toward several exciting directions:

| Trend | Description | Expected Impact |

|---|---|---|

| Industry 4.0 Integration | Full digitalization and connectivity with smart factories | Improved efficiency and predictive maintenance |

| Sustainable Manufacturing | Focus on energy recovery and recyclable materials | Reduced environmental footprint |

| Hybrid Material Processing | Combining multiple materials in single compaction cycles | Enhanced product functionality |

| Nanopowder Compaction | Processing of nano-scale powders for advanced applications | Superior material properties |

Operational Considerations and Best Practices

Successful implementation of powder compacting technology requires attention to several critical factors:

Material Selection and Preparation

Proper powder characterization, including particle size distribution, flow characteristics, and compressibility, is essential for achieving desired compaction results.

Tooling Design and Maintenance

Die design significantly impacts part quality and production efficiency. Regular maintenance and proper lubrication extend tooling life and ensure consistent performance.

Process Optimization

Systematic optimization of compaction pressure, speed, and dwell time is crucial for achieving optimal density and mechanical properties in the final product.

Conclusion

Powder compacting press machines have established themselves as vital equipment in modern manufacturing. Their ability to produce high-quality, complex components with exceptional efficiency continues to drive innovation across multiple industries. As technology advances, we can expect even greater precision, flexibility, and sustainability from these remarkable machines, further solidifying their position in the manufacturing landscape.