Progressive Dies: The Engine of High-Volume Metal Stamping

In the world of modern manufacturing, efficiency, precision, and speed are paramount. Progressive dies stand as a cornerstone technology in metal stamping, enabling the mass production of complex metal parts with remarkable consistency and cost-effectiveness. Unlike single-stage dies that perform one operation per press stroke, progressive dies incorporate a series of stamping stations arranged in a linear sequence on a single die set. A metal strip, or coil, feeds through these stations with each press stroke, undergoing a different operation—such as cutting, bending, punching, or coining—until a finished part is ejected at the final station. This continuous process makes progressive dies indispensable for industries ranging from automotive and electronics to appliances and aerospace.

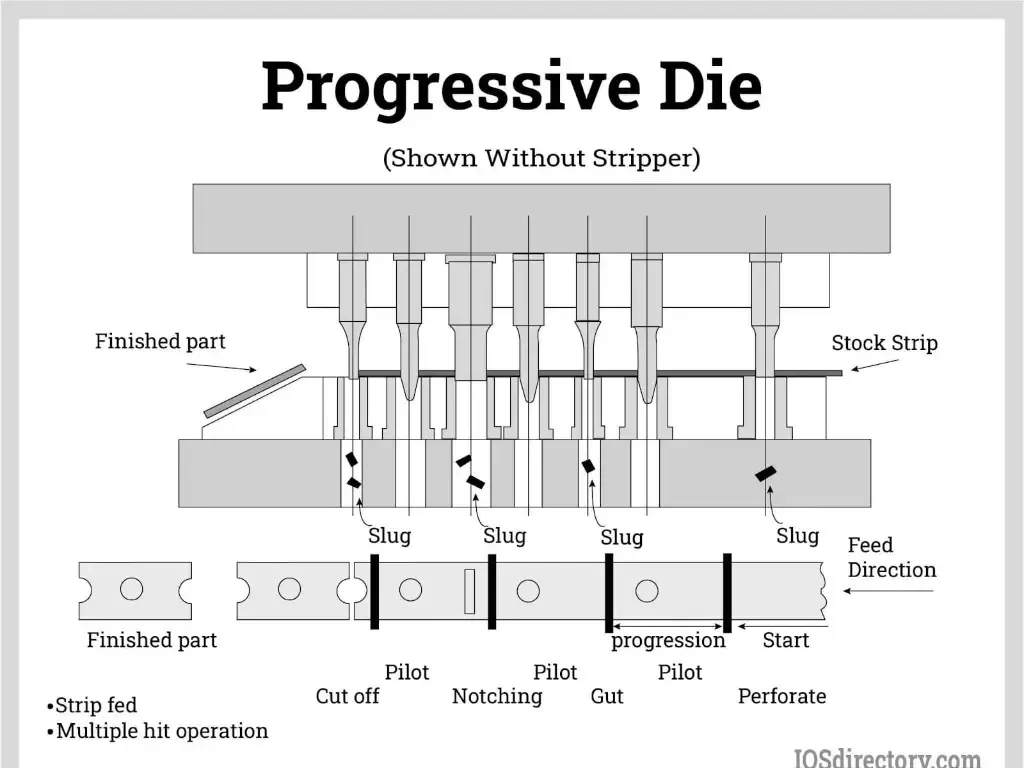

Figure 1: Schematic layout of a typical progressive die, showing material flow through multiple stations.

Core Components and Working Principle

A progressive die is a sophisticated assembly of numerous components working in unison. The key elements include the die set (upper and lower shoes), the strip guide or carrier, pilots for precise alignment, and individual stations equipped with specific punches and dies. The process begins with a coil of metal being fed into the press. With each cycle of the press ram:

- The strip advances a predetermined distance (the feed length).

- The ram descends, and all stations act on the strip simultaneously.

- Different sections of the strip undergo different operations; one section might be pierced while another is blanked, and a third from the previous stroke is formed.

- As the strip exits the final station, a completed part is sheared off or released.

This synchronized action means that with every stroke, a new part is completed, leading to exceptionally high production rates, often reaching hundreds of parts per minute.

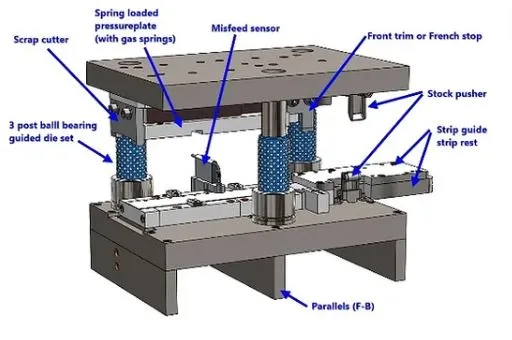

Figure 2: Close-up view of a precision progressive die tool, highlighting its intricate components.

Advantages of Using Progressive Dies

The adoption of progressive die stamping offers compelling benefits for high-volume production:

- High Efficiency and Speed: Simultaneous multiple operations drastically reduce cycle time per part.

- Superior Consistency and Precision: Once the die is precisely set up, it produces parts with extremely tight tolerances and repeatability.

- Reduced Labor Costs: The process is highly automated, requiring minimal operator intervention once running.

- Material Efficiency: Nesting parts closely on the strip minimizes scrap material. The skeleton web itself often acts as a carrier, eliminating the need for separate handling.

- Integration of Complex Operations: Multiple complex features can be formed in a single pass, eliminating secondary operations.

Comparison: Progressive Die vs. Other Stamping Methods

| Feature | Progressive Die | Compound Die | Transfer Die |

|---|---|---|---|

| Operation Principle | Multiple stations on a single die; strip-fed. | Multiple operations at a single station; sheet-fed. | Individual parts transferred between separate dies. |

| Production Speed | Very High | Moderate | High |

| Part Complexity | Moderate to High | Moderate | Very High (3D parts) |

| Tooling Cost | High | Moderate | Very High |

| Best For | High-volume, flat or moderately formed parts (brackets, connectors, leads). | Medium-volume parts requiring precision blanking and piercing. | High-volume, complex 3D parts (automotive body panels, deep-drawn cans). |

Design and Manufacturing Considerations

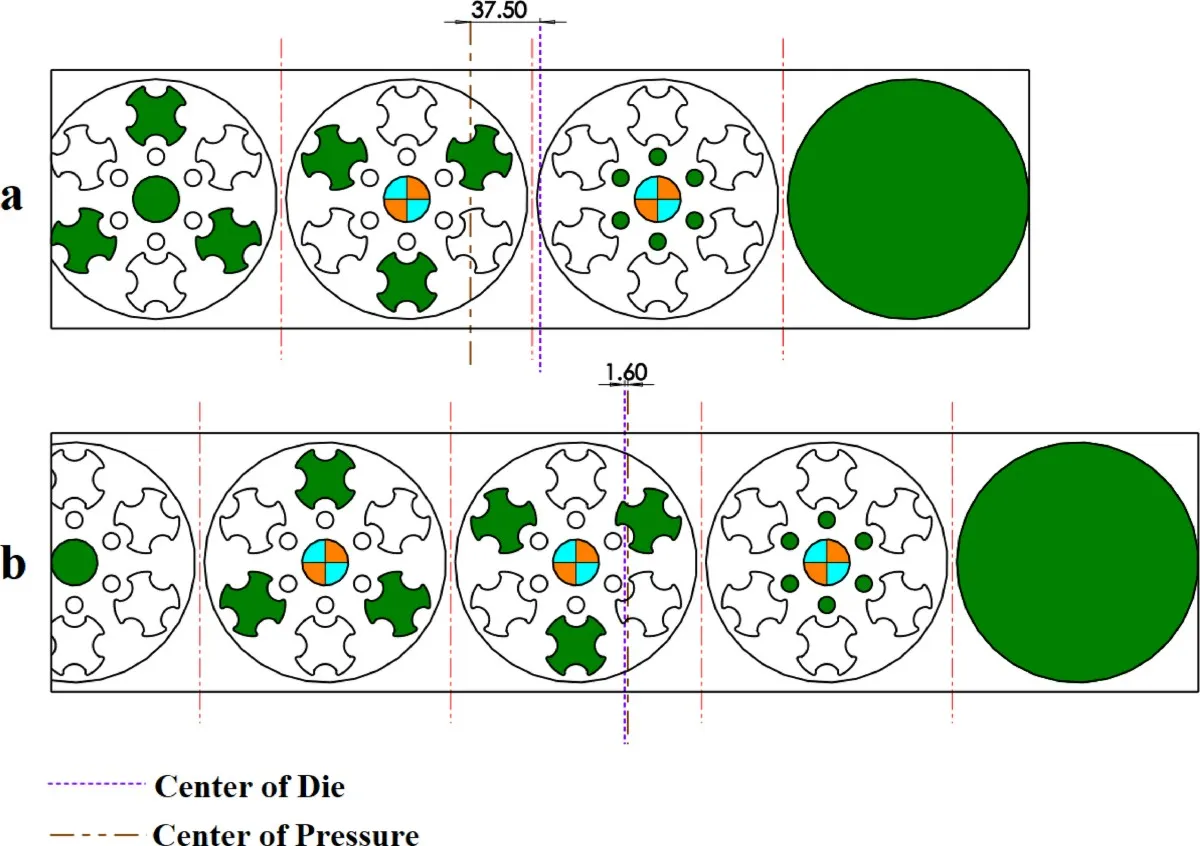

Designing a progressive die is a complex engineering task that requires meticulous planning. The process, known as strip layout or process planning, is critical to success. Engineers must determine the sequence of operations, the number of stations, the feed pitch, and the positioning of pilots and carriers. Advanced CAD/CAM software and simulation tools are used to model the metal flow, predict stresses, and prevent defects like tearing or wrinkling. The die itself is typically manufactured from high-grade tool steels (like D2 or A2) and often incorporates hardened inserts, springs, and nitrogen gas cylinders for precise actuation.

Key Design Steps for a Progressive Die:

- Part Analysis: Review part drawing, tolerances, material, and volume requirements.

- Strip Layout Development: Plan the station sequence and material flow to ensure formability and minimize scrap.

- Die Design: Detail all components in CAD, considering strength, wear, and maintenance access.

- Simulation & Validation: Use Finite Element Analysis (FEA) to simulate stamping and identify potential issues.

- Precision Machining & Assembly: Fabricate components using CNC machining, wire EDM, and grinding, followed by skilled assembly.

- Tryout & Sampling: Test the die in a press, adjust settings, and produce sample parts for approval.

Figure 3: 3D CAD model of a progressive die strip layout, crucial for virtual validation before manufacturing.

Applications in Modern Industry

Progressive dies are ubiquitous in sectors that demand high volumes of precision metal components. In the automotive industry, they produce electrical connectors, bracket assemblies, fuse boxes, and intricate engine parts. The electronics sector relies on them for manufacturing lead frames, shielding cans, and connector pins with extreme precision. Appliance manufacturers use progressive dies for parts like heat sinks, contacts, and various internal brackets. The technology's ability to maintain consistency across millions of cycles makes it a fundamental enabler of mass production as we know it.

Challenges and Future Trends

Despite their advantages, progressive dies present challenges. The initial cost and lead time for design and manufacturing are significant, making them economical only for high-volume production. They also require high-tonnage, precision presses and skilled technicians for setup and maintenance. Looking forward, trends like the integration of Industry 4.0 sensors for real-time monitoring of die health and part quality, the use of advanced coatings to extend tool life, and the development of more sophisticated simulation software are shaping the future. These advancements aim to reduce downtime, increase flexibility for shorter production runs, and push the boundaries of part complexity achievable in a single progressive die.

In conclusion, the progressive die remains a vital, evolving technology in metal stamping. Its unique combination of speed, precision, and efficiency solidifies its role as the engine driving the production of countless essential components in our everyday lives, from the car we drive to the smartphone in our pocket.