Servo Press Manufacturer - The Future of Precision Forming

In the realm of industrial manufacturing, precision, efficiency, and flexibility are paramount. Servo press technology, developed by leading servo press manufacturers, has emerged as a transformative force, redefining how metal forming, stamping, and forging operations are performed. Unlike traditional mechanical or hydraulic presses, servo presses utilize advanced servo motor technology to provide unparalleled control over the slide motion, force, and speed. This article delves into the world of servo press manufacturing, exploring its benefits, applications, and key considerations when selecting a manufacturer.

What is a Servo Press?

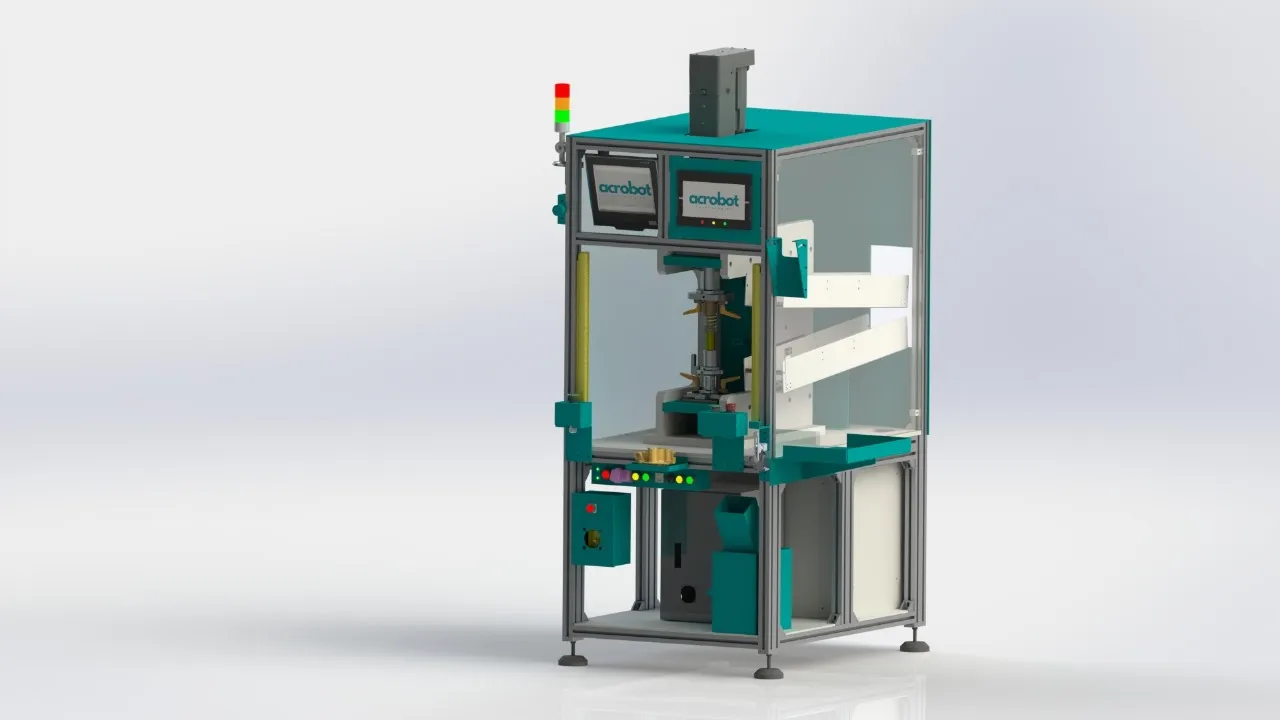

A servo press is a type of press machine driven by a servo motor instead of a conventional constant-speed AC motor, flywheel, and clutch. This fundamental difference allows for complete programmability of the ram's movement. Manufacturers can precisely control the slide position, velocity, and tonnage throughout the entire press cycle, from the approach and forming to the release and return.

Key Advantages of Servo Press Technology

Servo press manufacturers design their machines to offer a multitude of advantages over traditional presses, making them a superior choice for modern, high-value production environments.

1. Unmatched Precision and Control

The programmable nature of the servo motor allows for exact control of the slide motion. This enables the implementation of optimized forming profiles, such as dwells at bottom dead center (BDC) for improved part quality or reduced velocities during contact to minimize shock and tool wear.

2. Enhanced Flexibility

One press can be programmed with multiple stroke profiles to run different jobs efficiently. This eliminates the need for changeovers involving mechanical adjustments to the drive system, significantly reducing downtime and increasing production agility.

3. Improved Energy Efficiency

Servo presses consume energy only during active motion, unlike traditional presses that constantly rotate a heavy flywheel. This can lead to energy savings of 30% to 60%, reducing both operational costs and the carbon footprint.

4. Superior Part Quality

The precise control minimizes defects like cracking, wrinkling, and springback. The ability to control the strain rate in materials like high-strength steel and aluminum is crucial for achieving consistent, high-quality parts.

5. Reduced Noise and Vibration

Without the constant engagement and disengagement of a clutch or the inertia of a flywheel, servo presses operate much more quietly and with less vibration, contributing to a better working environment.

Applications Across Industries

Servo presses manufactured today are versatile machines found in a wide array of industries.

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Stamping body panels, forming gears, forging connectors | High precision for complex geometries, material savings |

| Electronics | Precision stamping of connectors, shielding cans, and micro-components | Miniaturization capability, reduced burrs |

| Aerospace | Forming turbine blades, structural components | Ability to work with hard-to-form alloys, repeatability |

| Medical | Manufacturing surgical instruments, implantable devices | Ultra-clean processes, extreme precision |

| Consumer Goods | Producing appliance parts, jewelry, cutlery | Flexibility for short runs, excellent surface finish |

Choosing the Right Servo Press Manufacturer

Selecting a reliable servo press manufacturer is critical to ensuring long-term productivity and return on investment. Here are the key factors to consider:

Technical Expertise and Innovation

Look for a manufacturer with a strong R&D department and a proven track record of innovation. They should offer advanced features like integrated IoT connectivity for predictive maintenance and data analytics.

Build Quality and Durability

The frame, guides, and drive components must be built to the highest standards to maintain accuracy under high loads over many cycles. Robust construction is non-negotiable.

Control System and Software

The user interface should be intuitive, and the software powerful. Easy programming of motion profiles, force monitoring, and diagnostic capabilities are essential for operators.

Service and Support

Global service networks, readily available spare parts, and comprehensive technical support are vital for minimizing downtime and ensuring the press operates at peak performance throughout its lifecycle.

Customization Capabilities

A top-tier manufacturer will offer customization options to tailor the press's tonnage, bed size, stroke length, and automation interfaces to your specific production needs.

The Future of Servo Press Manufacturing

The future is bright for servo press technology. Manufacturers are continuously integrating smarter features, such as AI-driven optimization of forming parameters based on real-time feedback, enhanced connectivity for Industry 4.0 smart factories, and developments in direct-drive technology for even greater efficiency and speed. As materials become more advanced and part designs more complex, the role of the sophisticated servo press will only become more central to modern manufacturing.

In conclusion, partnering with an innovative and reliable servo press manufacturer is not just an equipment purchase; it's an investment in the future of manufacturing capability, offering unprecedented levels of control, efficiency, and quality that are essential for staying competitive in today's market.