Servo Press vs Mechanical Press: A Comprehensive Comparison

The manufacturing industry has witnessed significant technological advancements in press machinery, with servo presses and mechanical presses representing two distinct approaches to metal forming and stamping operations. This comprehensive analysis explores the fundamental differences, advantages, and applications of both technologies, providing manufacturers with essential insights for making informed equipment decisions.

Fundamental Operating Principles

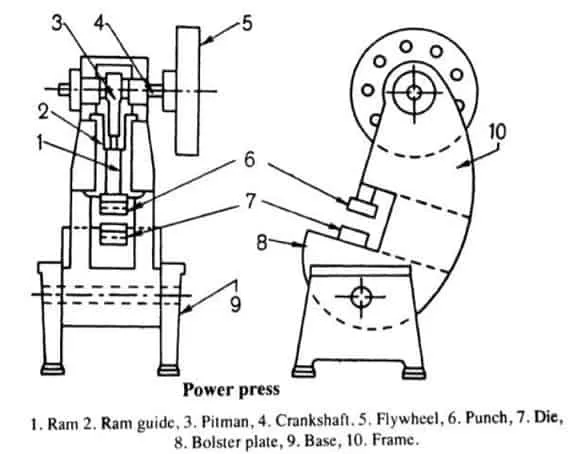

Mechanical Press Technology

Traditional mechanical presses have been the backbone of manufacturing for over a century, operating on relatively simple mechanical principles. These presses utilize a flywheel system driven by an electric motor, which stores rotational energy and transfers it through a clutch mechanism to the ram. The motion follows a fixed path determined by the press design, typically using eccentric gears or crankshafts to convert rotational motion into linear movement.

The fixed stroke length and speed characteristics of mechanical presses make them suitable for high-volume production runs where consistency and speed are paramount. However, this rigidity also represents their primary limitation in adapting to varying production requirements.

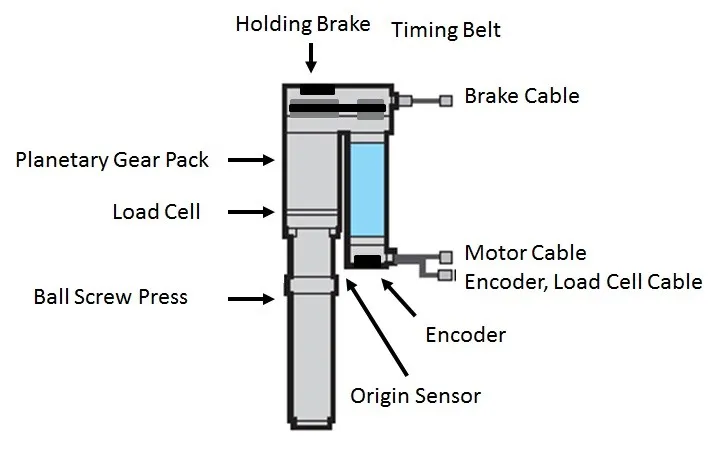

Servo Press Technology

Servo presses represent the modern evolution of press technology, incorporating computer-controlled servo motors that directly drive the ram without traditional mechanical components. These systems use advanced motion controllers and feedback systems to precisely manage every aspect of the press cycle, from approach speed to forming velocity and return stroke.

The programmable nature of servo presses allows for unprecedented flexibility in motion profiles, enabling manufacturers to optimize each phase of the pressing operation for specific materials and part geometries. This digital control extends to monitoring systems that can detect abnormalities and adjust parameters in real-time.

Performance Comparison

| Parameter | Servo Press | Mechanical Press |

|---|---|---|

| Speed Control | Fully programmable throughout stroke | Fixed by mechanical design |

| Stroke Length | Adjustable and programmable | Fixed mechanical stroke |

| Energy Consumption | 30-60% lower than mechanical | Higher due to constant flywheel rotation |

| Noise Level | Significantly reduced (10-15 dB lower) | Higher noise from mechanical components |

| Setup Time | Reduced through programmable settings | Longer mechanical adjustments required |

| Maintenance Requirements | Lower (no clutch/brake wear) | Higher mechanical component wear |

| Initial Investment | Higher upfront cost | Lower initial purchase price |

Operational Advantages and Limitations

Servo Press Advantages

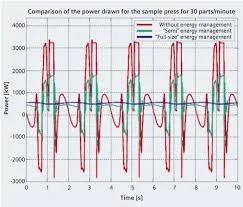

Servo presses offer numerous operational benefits that justify their higher initial investment. The ability to program optimal motion profiles for specific materials significantly improves part quality and reduces scrap rates. Energy efficiency is dramatically enhanced because servo motors only consume power during active pressing operations, unlike mechanical presses that continuously rotate heavy flywheels.

The flexibility of servo technology enables manufacturers to perform complex forming operations in a single press that would traditionally require multiple machines or secondary operations. This includes capabilities like dwell times at bottom dead center, variable approach speeds, and multi-step forming sequences within a single stroke.

Mechanical Press Strengths

Despite the technological advantages of servo systems, mechanical presses maintain relevance in specific applications. Their simpler mechanical design translates to lower initial costs and potentially longer service life in high-volume, single-operation applications. The inherent kinetic energy stored in rotating flywheels provides consistent power delivery that can be advantageous for heavy forming operations.

Mechanical presses also benefit from extensive industry familiarity, with maintenance procedures and spare parts availability well-established in most manufacturing regions. For operations requiring extremely high cycle speeds with minimal variability, mechanical presses can still provide cost-effective solutions.

Application-Specific Considerations

Ideal Applications for Servo Presses

Servo presses excel in environments requiring flexibility, precision, and energy efficiency. They are particularly valuable in:

- Prototyping and short production runs requiring frequent changeovers

- Operations involving delicate or expensive materials where reduced scrap rates are critical

- Complex forming operations requiring multiple motions within a single cycle

- Manufacturing facilities with strict energy consumption targets

- Environments where noise reduction is a priority

Where Mechanical Presses Remain Competitive

Mechanical presses maintain competitive advantages in specific scenarios:

- High-volume production of identical parts with minimal changeovers

- Operations requiring the high inertial energy of rotating flywheels

- Budget-constrained operations where initial investment is the primary concern

- Applications where extreme cycle speeds are more important than flexibility

- Environments with limited technical support for advanced electronic systems

Economic Analysis and ROI Considerations

The decision between servo and mechanical press technology requires careful economic analysis beyond initial purchase price. While servo presses command premium pricing—typically 20-40% higher than comparable mechanical presses—their operational benefits can deliver compelling return on investment through:

- Energy savings of 30-60% reducing operational costs

- Reduced scrap rates improving material utilization

- Lower maintenance costs and reduced downtime

- Increased production flexibility enabling faster response to market changes

- Improved part quality reducing inspection and rework requirements

Future Trends and Technology Development

The evolution of press technology continues to accelerate, with servo systems incorporating increasingly sophisticated control algorithms and connectivity features. Industry 4.0 integration enables real-time monitoring, predictive maintenance, and data-driven optimization of press operations. Hybrid systems combining elements of both technologies are emerging, offering intermediate solutions with balanced cost and performance characteristics.

As material science advances and manufacturing requirements become more demanding, the flexibility and precision of servo technology positions it for continued market share growth. However, mechanical press manufacturers continue to innovate with improved designs, materials, and control systems to maintain competitiveness in specific market segments.

Conclusion: Making the Right Choice for Your Operation

The selection between servo and mechanical press technology depends on multiple factors including production volume, part variety, material characteristics, and economic considerations. Servo presses offer unparalleled flexibility, precision, and efficiency for operations requiring adaptability and advanced capabilities. Mechanical presses remain viable for high-volume, single-operation applications where their simplicity and lower initial cost provide competitive advantages.

Manufacturers should conduct thorough analysis of their specific requirements, considering both immediate needs and long-term strategic direction. As technology continues to evolve, the performance gap between these technologies may widen, but both will likely maintain relevance in their respective optimal application spaces for the foreseeable future.