Servo Pressure Regulator: Precision Control in Fluid Power Systems

In the complex world of industrial automation and fluid power systems, maintaining precise and stable pressure is paramount. Among the various technologies employed for this critical task, the servo pressure regulator stands out as a sophisticated and highly accurate solution. This device represents a significant advancement over traditional mechanical regulators, offering unparalleled control for applications where pressure consistency directly impacts product quality, process efficiency, and system safety.

Fundamental Working Principle

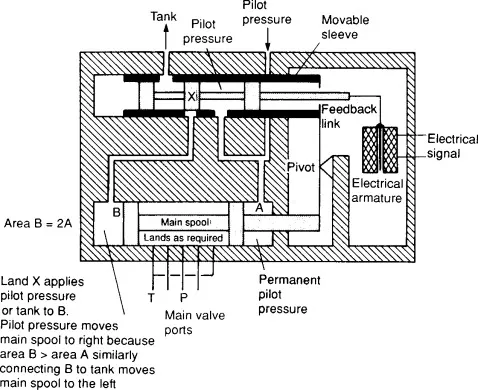

At its core, a servo pressure regulator operates on a closed-loop control principle. It continuously monitors the downstream (output) pressure and compares it to a setpoint—a desired pressure value commanded by an external electrical signal (typically 4-20 mA or 0-10 VDC). Any deviation between the actual pressure and the setpoint generates an error signal.

This error signal is processed by an integrated electronic controller, which then drives a servo valve or a proportional solenoid. This actuation adjusts the pilot stage of the regulator, modulating the flow of fluid or gas to the main regulating element (such as a diaphragm or piston). This precise modulation either increases or decreases the opening of the main valve, thereby correcting the output pressure until the error is minimized, often to within ±0.1% of the setpoint.

Key Components and Their Roles

- Pressure Sensor/Transducer: Measures the actual output pressure and provides feedback to the controller.

- Electronic Controller: The "brain" that compares setpoint and feedback, calculates the error, and sends a correction signal.

- Servo Actuator (Valve/Solenoid): Converts the electrical correction signal into precise mechanical movement.

- Pilot Stage: A low-power stage controlled by the servo actuator that influences the main valve.

- Main Regulating Valve: The high-flow component that directly controls the system pressure.

Types and Configurations of Servo Pressure Regulators

Servo pressure regulators are designed to handle various media and operational requirements. The primary classification is based on the medium being controlled.

| Type | Medium | Key Features | Typical Applications |

|---|---|---|---|

| Electro-Pneumatic | Compressed Air / Gas | Fast response, clean operation, high precision. | Valve testing, packaging machines, pneumatic actuators. |

| Electro-Hydraulic | Hydraulic Oil | High power density, handles high pressures, robust construction. | Presses, injection molding, material testing (UTM). |

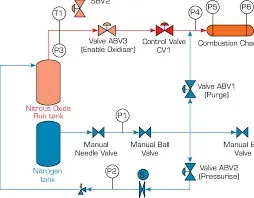

| Liquid Service | Water, Chemicals, Fuels | Corrosion-resistant materials, seals compatible with media. | Chemical dosing, fuel cell testing, water jet cutting. |

Critical Advantages Over Conventional Regulators

The integration of electronic feedback and control elevates servo regulators far beyond the capabilities of mechanical, spring-loaded regulators.

1. Exceptional Accuracy and Repeatability

They eliminate the droop (offset) common in mechanical regulators, maintaining the exact setpoint regardless of flow changes or supply pressure fluctuations.

2. Remote Control and Programmability

Pressure setpoints can be changed instantly via software, enabling complex pressure profiles and seamless integration into PLC-controlled systems.

3. Dynamic Response

Capable of very fast response times, they can track and maintain rapidly changing setpoints, which is essential for simulating dynamic conditions or cyclic processes.

4. Diagnostic and Communication Capabilities

Many models offer digital communication (e.g., PROFIBUS, Ethernet/IP) for real-time monitoring of pressure, status, and health, facilitating predictive maintenance.

Primary Industrial Applications

The unique capabilities of servo pressure regulators make them indispensable in high-stakes industries.

Manufacturing and Automation

Used in leak testing of components, where precise pressure ramps and holds are critical. They control clamping force in injection molding and pressure in die casting machines to ensure part quality.

Testing and Simulation

In universal testing machines, they apply precise load pressures. They simulate altitude or depth pressure in environmental chambers and are crucial in fuel cell and battery test stands for gas pressure control.

Aerospace and Automotive

Employed in brake system testing, tire pressure simulation, and controlling actuator pressure in flight control system rigs.

Selection and Integration Considerations

Choosing the right servo pressure regulator requires careful analysis of several parameters:

- Pressure Range: Required inlet, outlet, and relief pressures.

- Flow Capacity (Cv or Kv value): Must meet maximum system flow demand.

- Medium Compatibility: Material of wetted parts (stainless steel, brass, special alloys) and seal material (Viton, EPDM, PTFE).

- Control Signal & Communication: Analog I/O, digital interfaces, and protocol requirements.

- Accuracy & Response Time: Specified as a percentage of full scale and step-response time.

- Environmental Conditions: Temperature, humidity, and area classification (e.g., explosion-proof).

Conclusion: Enabling the Future of Precision Control

The servo pressure regulator is more than just a valve; it is a fully integrated mechatronic system that bridges the gap between digital control signals and physical fluid power. As industries push towards greater precision, efficiency, and connectivity (Industry 4.0), the role of these intelligent regulators becomes increasingly central. Their ability to provide stable, accurate, and responsive pressure control makes them a foundational technology for advanced manufacturing, rigorous testing, and innovative research, ensuring processes are not only controlled but optimized for peak performance.