The Evolution of Spinning Machine Technology: A Comprehensive Overview

The spinning machine stands as one of the most transformative inventions in human history, fundamentally reshaping textile production and catalyzing the Industrial Revolution. From its humble beginnings as simple manual devices to today's computerized marvels, spinning technology has continuously evolved to meet the demands of global textile manufacturing. This article explores the fascinating journey of spinning machine invention and development, highlighting key innovators, technological breakthroughs, and the future trajectory of this essential technology.

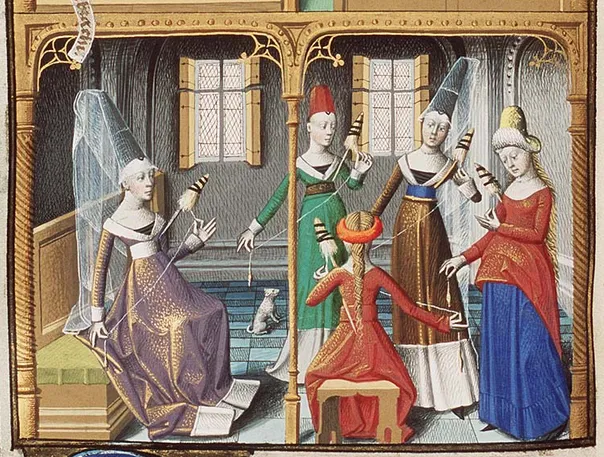

Early Beginnings: The Pre-Industrial Spinning Methods

Before the invention of mechanical spinning devices, textile production relied entirely on manual labor using simple tools like the spindle and distaff. The spinning wheel, believed to have originated in India between 500 and 1000 AD, represented the first significant technological advancement in spinning technology. These early devices increased productivity but still limited output to what a single operator could produce.

The limitations of these manual methods became increasingly apparent as demand for textiles grew in 18th century Europe. The inability to produce yarn quickly enough to keep up with weaving innovations created what economists termed the "spin gap" - a bottleneck in textile production that would inspire a wave of technological innovation.

The Industrial Revolution: Birth of Mechanical Spinning

Key Inventors and Their Contributions

The spinning machine as we recognize it today began taking shape during the Industrial Revolution, with several inventors making crucial contributions:

| Inventor | Year | Contribution | Significance |

|---|---|---|---|

| James Hargreaves | 1764 | Spinning Jenny | First multi-spindle spinning frame |

| Richard Arkwright | 1769 | Water Frame | First continuous spinning machine |

| Samuel Crompton | 1779 | Spinning Mule | Combined features of jenny and water frame |

The Spinning Jenny: Multiplying Productivity

James Hargreaves' Spinning Jenny, patented in 1770, represented a quantum leap in spinning technology. Unlike earlier devices that could only spin one thread at a time, the jenny could initially spin eight threads simultaneously, with later models capable of handling up to 120 spindles. This multiplication of productivity addressed the spin gap directly and laid the foundation for factory-based textile production.

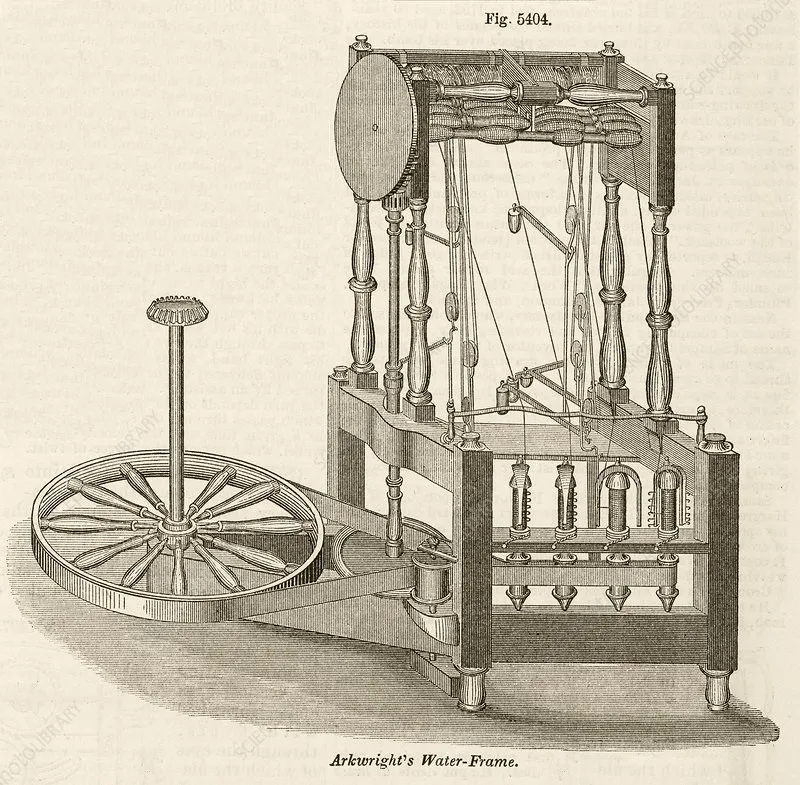

Arkwright's Water Frame: Powering the Revolution

Richard Arkwright's water frame, patented in 1769, introduced two critical innovations: it used water power rather than human effort, and it produced stronger yarn suitable for warp threads (the longitudinal threads in weaving). This invention not only increased production capacity but also improved yarn quality, enabling the production of all-cotton textiles rather than cotton-linen blends.

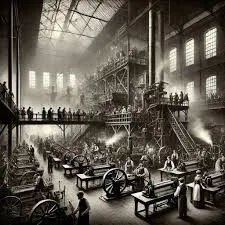

Technological Advancements in the 19th Century

The 19th century witnessed significant refinements to spinning technology as the Industrial Revolution matured. The most important development was the widespread adoption of steam power, which freed mills from their dependency on water sources and allowed for larger-scale operations in urban centers.

During this period, the self-acting mule, invented by Richard Roberts in 1825, automated the previously manual process of moving the carriage on spinning mules. This innovation further reduced labor requirements while increasing consistency and output quality. By the late 19th century, ring spinning began to emerge as the dominant technology, offering continuous operation and higher speeds than mule spinning.

Modern Spinning Technology: Automation and Computerization

Open-End Spinning

The mid-20th century introduced open-end or rotor spinning, which eliminated the need for spindles and drafting rollers entirely. Instead, this method separates fibers into a stream of air that deposits them onto the open end of a forming yarn, which rotates at high speed to insert twist. This technology significantly increased production speeds while reducing energy consumption and floor space requirements.

Computer-Integrated Manufacturing

Late 20th and early 21st century advancements have transformed spinning mills into highly automated, computer-integrated manufacturing facilities. Modern spinning machines feature:

- Automated doffing systems that remove full packages and replace them with empty tubes without stopping production

- Integrated monitoring systems that track production data and quality metrics in real-time

- Self-cleaning mechanisms that reduce maintenance requirements

- Energy-efficient drives and motors that minimize power consumption

The Future of Spinning Technology

As we look toward the future, several trends are shaping the next generation of spinning machines:

Sustainability Focus

Manufacturers are increasingly developing energy-efficient spinning technologies that reduce power and water consumption. New systems are being designed to handle recycled fibers more effectively, supporting the circular economy in textiles.

Industry 4.0 Integration

The fourth industrial revolution is bringing smart manufacturing concepts to spinning technology. Future spinning machines will feature enhanced IoT connectivity, predictive maintenance capabilities, and artificial intelligence systems that optimize production parameters in real-time based on fiber properties and desired yarn characteristics.

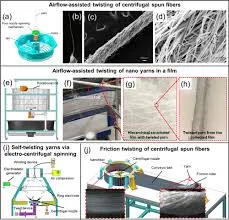

Nanotechnology and Advanced Materials

Emerging technologies are enabling the development of spinning systems capable of handling nanofibers and smart materials that incorporate functional properties like conductivity, antimicrobial protection, or temperature regulation directly into the yarn structure.

Impact on Global Textile Industry

The evolution of spinning technology has profoundly impacted global economics, trade patterns, and labor markets. The increased productivity of modern spinning machines has made textile products more affordable worldwide while shifting production to regions with favorable economic conditions. Today's state-of-the-art spinning facilities can produce yarn with exceptional consistency and quality at speeds that would have been unimaginable to early inventors.

| Time Period | Production Rate (kg/hr) | Labor Required (hours/kg) | Energy Efficiency Index |

|---|---|---|---|

| Manual Spinning (18th century) | 0.02 | 50 | 100 |

| Early Mechanical (1800) | 0.2 | 5 | 45 |

| Modern Ring Spinning (1950) | 2.5 | 0.4 | 25 |

| Contemporary Rotor Spinning (2020) | 15 | 0.07 | 12 |

From the simple spinning jenny to today's computerized systems, the spinning machine has undergone a remarkable transformation over three centuries. Each innovation has built upon previous technologies, driving increases in productivity, quality, and efficiency. As we look to the future, spinning technology continues to evolve, incorporating sustainability principles and digital technologies that will shape textile manufacturing for decades to come. The story of the spinning machine inventor is far from over—it is simply entering a new chapter defined by smart technology and sustainable practices.