In the realm of industrial manufacturing, the mechanical press stands as a cornerstone for shaping, cutting, and forming materials—primarily metals. However, the efficiency, safety, and quality of these operations hinge not just on the machine itself, but on a meticulously crafted set of instructions known as the mechanical press recipe. This recipe is a comprehensive digital or documented protocol that defines every critical parameter of a pressing operation, transforming raw power into precise, repeatable, and high-quality production.

Core Components of a Mechanical Press Recipe

A robust mechanical press recipe is an amalgamation of several interdependent parameters. Neglecting any single component can lead to subpar parts, machine damage, or safety hazards.

1. Force and Tonnage Specifications

The required press force, measured in tons, is the recipe's foundation. It must be calculated based on the material's shear strength, thickness, and the total cutting or forming area. Exceeding the press's rated capacity is a primary cause of failure.

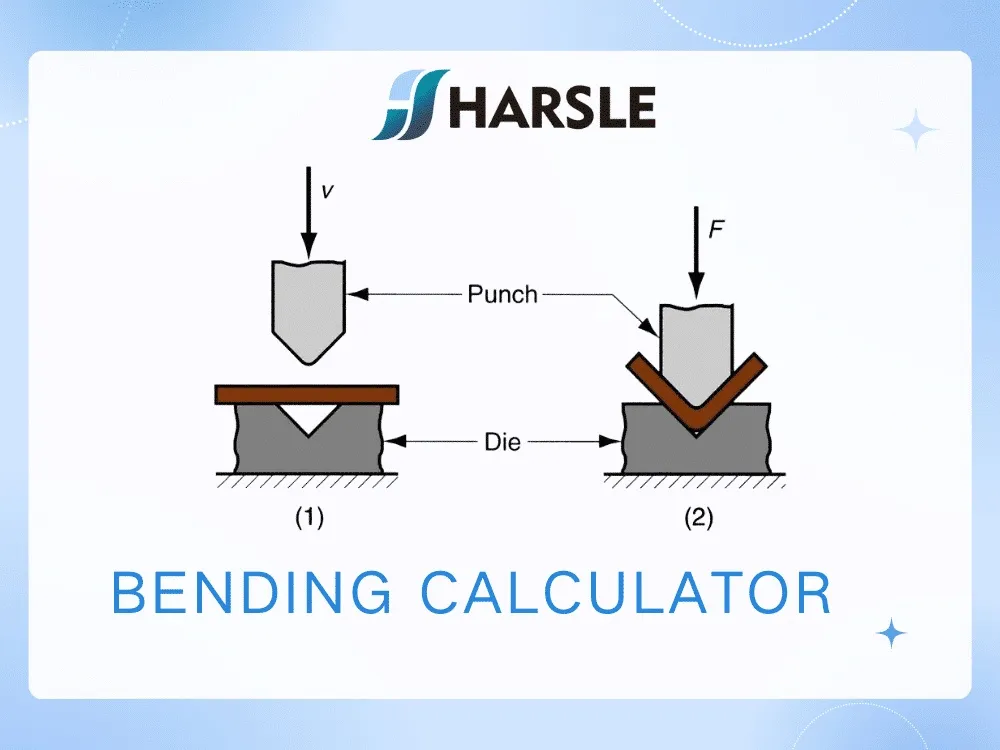

2. Stroke Length and Slide Position

This defines the vertical travel distance of the press slide (ram) from top dead center (TDC) to bottom dead center (BDC). The recipe specifies the exact start and end points for the forming action, ensuring consistent part depth and proper material flow.

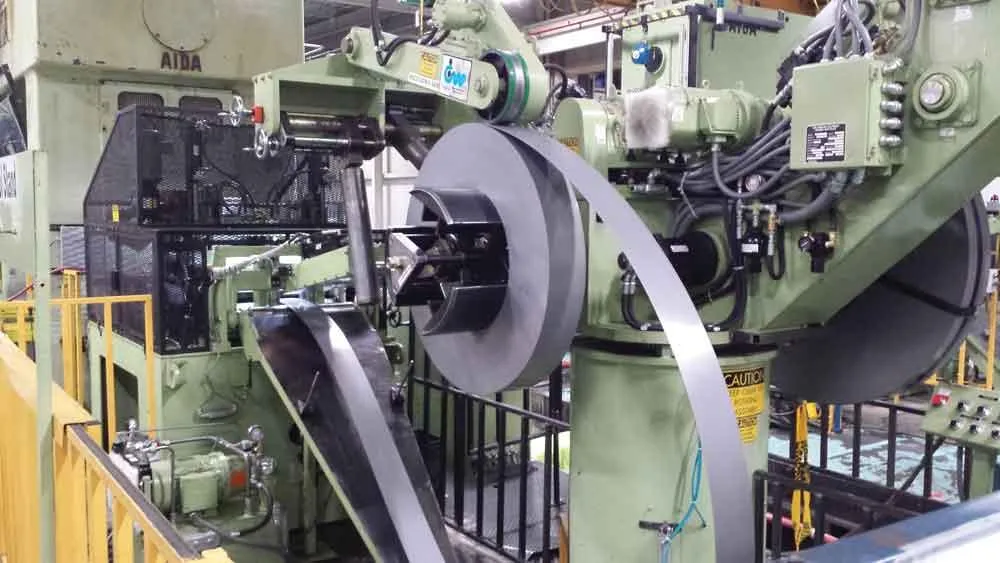

3. Speed and Feed Rates

The speed of the slide (strokes per minute - SPM) and the feed rate of the material coil or blank are synchronized in the recipe. Optimal speeds maximize output while preventing issues like material tearing or excessive die wear.

4. Die and Tooling Data

The recipe includes specific die identification, shut height settings, and guidance on cushion pressure (if applicable) for blank holders in drawing operations. This ensures the correct tooling is used and set up accurately.

Recipe Development and Optimization Process

Creating an effective recipe is a systematic engineering process, often leveraging both simulation software and empirical testing.

| Development Phase | Key Activities | Outcome |

|---|---|---|

| 1. Part & Material Analysis | Review part CAD model, material grade, thickness, and grain direction. | Determination of basic force, energy, and blank size requirements. |

| 2. Simulation (FEA) | Use software to simulate metal flow, stress, and potential defects (wrinkling, tearing). | Optimized forming speeds, pressures, and preliminary recipe parameters. |

| 3. Prototype Testing | Run initial trials on the press with soft tooling or sample dies. | Validation of simulations, adjustment of real-world parameters like lubrication amount. |

| 4. Final Recipe Documentation | Document all finalized parameters in a digital format (often integrated with press PLC). | A standardized, repeatable recipe for production. |

The Role of Sensors and IoT

Modern recipes are dynamic. Integrated sensors monitor real-time tonnage, slide position, and part ejection. The Internet of Things (IoT) allows recipes to be adjusted automatically based on sensor feedback, enabling predictive maintenance and consistent quality.

Impact on Quality, Safety, and Efficiency

A precise mechanical press recipe directly drives operational excellence across three key areas:

Quality Assurance

By eliminating guesswork, recipes ensure every part is produced within identical parameters, drastically reducing dimensional variation and defects. Statistical Process Control (SPC) data is often linked directly to recipe settings.

Operator and Machine Safety

Recipes enforce safe operating limits. They can be password-protected to prevent unauthorized changes to force or stroke settings, and they ensure safety devices like light curtains are interlocked correctly for the specific job.

Production Efficiency

Optimized recipes minimize cycle time and scrap. Quick changeover between jobs is facilitated by saving and retrieving digital recipes, a cornerstone of Lean Manufacturing and Single-Minute Exchange of Die (SMED) methodologies.

The future of mechanical press recipes lies in artificial intelligence and machine learning. AI algorithms can analyze production data from thousands of cycles to self-optimize recipes for even higher speed or lower energy consumption. Adaptive recipes will continuously fine-tune parameters in response to subtle material batch variations, heralding a new era of zero-defect manufacturing.

In conclusion, the mechanical press recipe is far more than a simple settings list; it is the encoded intelligence of the manufacturing process. As presses become more connected and intelligent, the recipe evolves from a static instruction set to a dynamic, self-improving algorithm, ensuring that this classic manufacturing technology continues to be a pillar of precision and productivity in the Industry 4.0 landscape.