The Ultimate Guide to CNC Tube Bending Machine Manufacturers

The manufacturing landscape has been revolutionized by Computer Numerical Control (CNC) technology, particularly in the realm of tube and pipe bending. CNC tube bending machines offer unparalleled precision, repeatability, and efficiency, making them indispensable in industries ranging from aerospace and automotive to furniture and construction. Choosing the right CNC tube bending machine manufacturer is a critical decision that impacts productivity, product quality, and ultimately, the bottom line. This guide provides a comprehensive overview of the key players, technologies, and considerations in this specialized field.

Leading CNC Tube Bending Machine Manufacturers

The global market for CNC tube benders is populated by a mix of long-established industry giants and innovative specialists. Manufacturers often differentiate themselves based on the machine's capacity (the diameter and wall thickness of tubes it can handle), the bending technology employed, and the sophistication of the control software.

Global Industry Leaders

Companies like BLM Group (Italy), Transfluid Maschinenbau GmbH (Germany), and Numalliance (France) are renowned for their high-end, robust machines capable of handling complex bending tasks with extreme accuracy. These manufacturers often cater to high-volume production environments like the automotive industry.

Specialized and Regional Manufacturers

Other notable manufacturers, such as Vogel (Germany), Taiyo America (Japan/USA), and CSM Machines (USA), may focus on specific niches, such as compact machines for small workshops or highly specialized benders for applications like heat exchangers or medical equipment.

Key Technologies in Modern CNC Tube Bending

Understanding the core technologies used by manufacturers is essential for making an informed purchase. The two primary bending methods dominate the market.

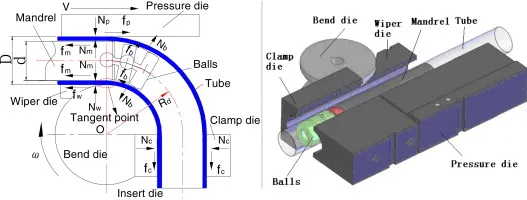

Rotary Draw Bending

This is the most common method for precision bending. It uses a die set (a bend die, clamp die, and pressure die) to form the tube around a fixed radius. This technique produces high-quality, wrinkle-free bends with excellent repeatability and is ideal for tight radii and complex geometries.

Roll Bending

Also known as pyramid rolling or three-roll bending, this method uses three rollers in a triangular formation to gradually curve the tube into large-radius arcs or circles. It is less precise than rotary draw bending but is perfect for creating large sweeps, coils, and architectural elements.

Critical Factors When Selecting a Manufacturer

Beyond the machine's specifications, several other factors related to the manufacturer itself are crucial for a successful long-term partnership.

| Factor | Description | Why It Matters |

|---|---|---|

| Technical Support & Service | Availability of installation, training, and maintenance services. | Minimizes downtime and ensures optimal machine performance throughout its lifecycle. |

| Software and Controls | User-friendliness and capabilities of the CNC software. | Intuitive software reduces programming time and errors, increasing overall efficiency. |

| Spare Parts Availability | The speed and ease with which replacement parts can be sourced. | Critical for quick repairs and maintaining production schedules. |

| Customization Options | Ability to tailor the machine to specific application needs. | Ensures the machine is a perfect fit for unique production requirements. |

The Future of CNC Tube Bending Manufacturing

Manufacturers are continuously innovating. Key trends include the integration of Internet of Things (IoT) capabilities for predictive maintenance and data analytics, increased use of robotic automation for loading and unloading, and advancements in simulation software that can predict material springback and potential defects before a single part is bent. Choosing a manufacturer that invests in R&D ensures your investment remains relevant and competitive for years to come.

In conclusion, selecting a CNC tube bending machine manufacturer is a strategic decision. By carefully evaluating the technical capabilities, support infrastructure, and innovative drive of potential partners, manufacturers can secure a solution that not only meets their current needs but also drives future growth and success.