Transfer Press vs Progressive Press: A Comprehensive Comparison

In the world of metal stamping and high-volume part manufacturing, two dominant technologies stand out: the transfer press and the progressive press. Both are pillars of modern industrial production, enabling the mass fabrication of complex components with remarkable precision and speed. However, their operational principles, capabilities, and ideal applications differ significantly. This article provides a detailed comparison to help engineers, production managers, and decision-makers select the optimal press system for their specific needs.

Fundamental Operating Principles

How a Progressive Press Works

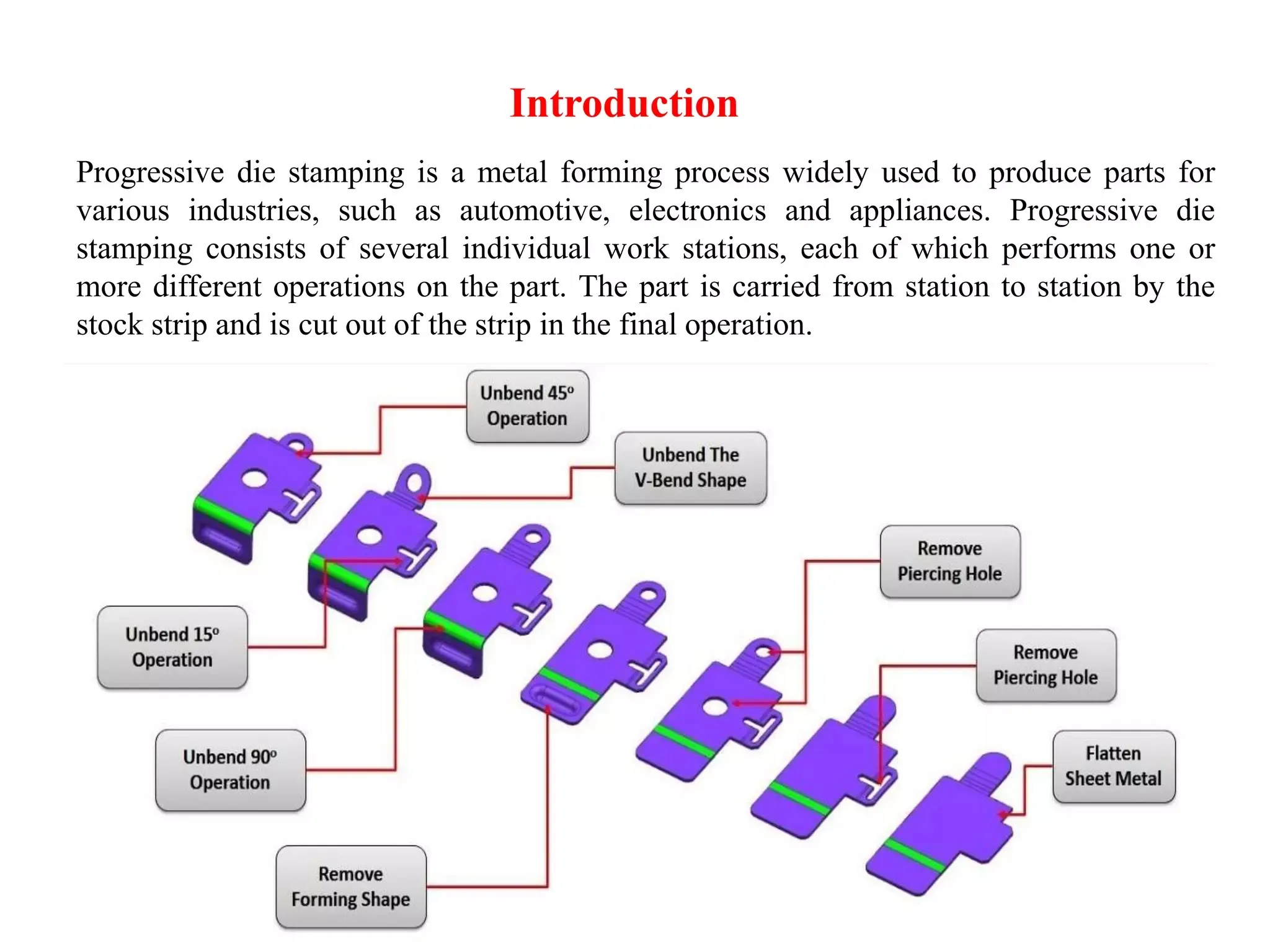

A progressive press operates using a single, long strip of metal coil fed through a series of stamping stations within a single die set. With each stroke of the press, simultaneous operations—such as punching, bending, and coining—are performed at different stations along the strip. The part remains attached to the carrier web until the final station, where it is severed and ejected as a finished piece. This creates a continuous, high-speed process.

How a Transfer Press Works

In contrast, a transfer press utilizes separate, individual presses or stations. A blank or partially formed part is mechanically transferred from one station to the next by a synchronized system of fingers, rails, or robots. Each station performs a distinct operation, and the part is completely separate from any carrier material throughout the process. This allows for greater flexibility in handling larger or more complex parts that may require reorientation between stages.

Key Comparative Analysis

The choice between these two technologies hinges on several critical factors, from part geometry to production volume and cost considerations.

| Comparison Factor | Progressive Press | Transfer Press |

|---|---|---|

| Material Utilization | Generally high, but requires a carrier web which creates some scrap. | Can be very high, as blanks are often nested efficiently and no carrier is needed. |

| Part Complexity & Size | Best for small to medium, relatively flat parts (e.g., brackets, contacts). | Excellent for large, deep-drawn, or complex 3D parts (e.g., automotive panels, sinks). |

| Production Speed (Strokes/Minute) | Very high (often 100+ SPM). Speed is limited by die complexity and feed length. | Moderate to high (20-60 SPM). Speed is limited by transfer mechanism and part mass. |

| Tooling Cost & Lead Time | High for complex progressive dies, but one die set serves the entire process. | Can be lower per individual station die, but multiple dies are required. |

| Flexibility & Changeover | Low. Changing a part requires a complete, complex die change. | Higher. Individual station dies can be modified or replaced more easily. |

| Secondary Operations | Limited. Most operations must be done in-line within the die. | Easily integrated (e.g., tapping, welding, assembly between stations). |

Advantages and Disadvantages

Advantages of Progressive Presses

Progressive presses excel in unparalleled speed for suitable parts, leading to the lowest cost per piece for extremely high-volume runs (millions of parts). The process is highly automated from coil to finished part, minimizing manual handling. It ensures consistent quality as all forming stages are mechanically linked within a single press stroke.

Disadvantages of Progressive Presses

The major limitation is design inflexibility; the part must be designed for a carrier strip. Initial tooling costs are exceptionally high and lead times are long. They are not suitable for large, bulky, or very deep-drawn components.

Advantages of Transfer Presses

Transfer presses offer superior flexibility in part design and sequence of operations. They can handle much larger and more complex parts, including those requiring drawing and ironing. Material savings can be significant, and the system allows for easier inspection and intervention between stations.

Disadvantages of Transfer Presses

They operate at slower cycle rates compared to progressive systems. The initial capital investment for the press and transfer system can be higher. The process generally requires more floor space and is mechanically more complex to maintain.

Application Scenarios and Selection Guide

Choosing the right press is a strategic decision. Use a Progressive Press when producing very high volumes of small, stampable parts like electrical connectors, lead frames, or simple brackets where speed is paramount. Opt for a Transfer Press for larger structural components, automotive body parts, appliances, or parts requiring deep draws and secondary operations. It is also the preferred choice for medium to high volumes where part design may change more frequently.

Summary and Final Thoughts

There is no universal "better" option between transfer and progressive presses. The progressive press is the undisputed champion of speed for high-volume, strip-fed components. The transfer press is the versatile specialist, capable of producing larger and more complex standalone parts with greater flexibility. The decision must be rooted in a thorough analysis of the part geometry, annual volume, material, budget, and future product roadmap. Understanding the core strengths and limitations of each system is the first step toward optimizing manufacturing efficiency and profitability.