Transfer Pressure Injection Molding: Process, Applications and Advantages

Introduction to Transfer Pressure Injection Molding

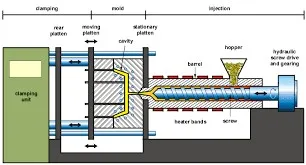

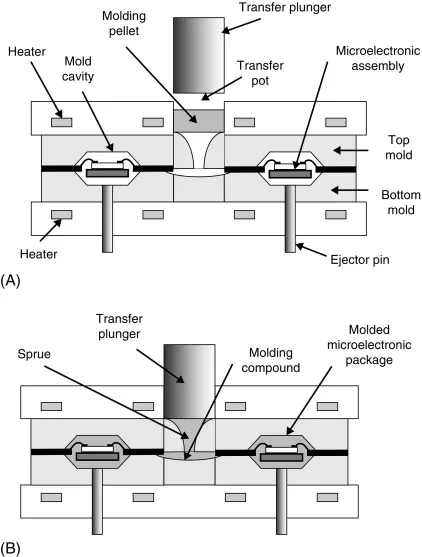

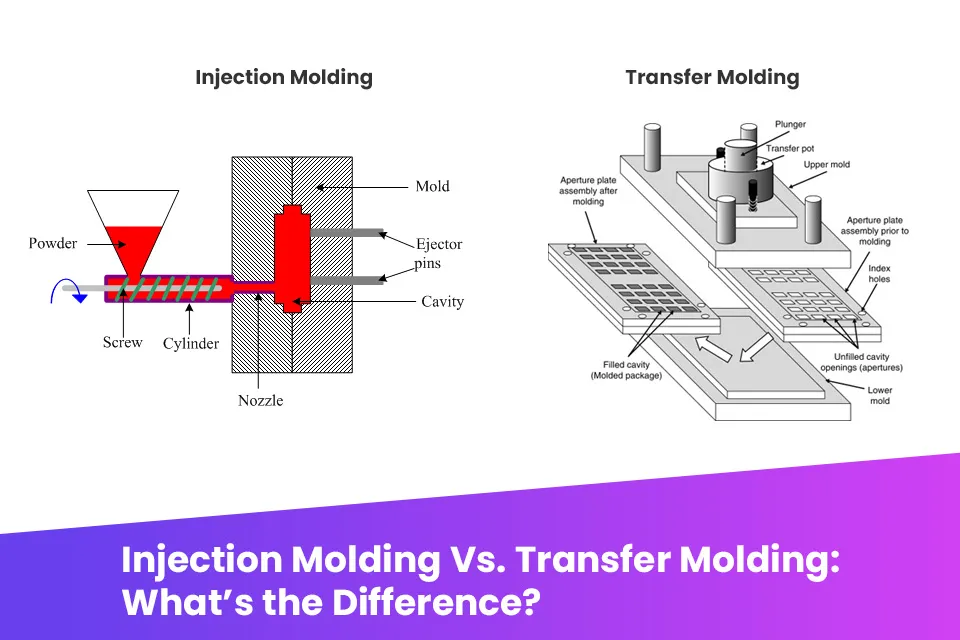

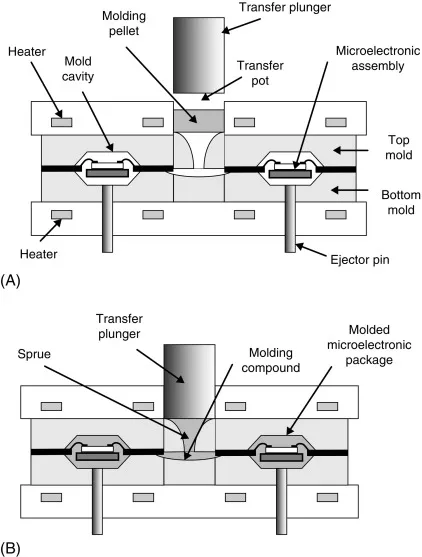

Transfer pressure injection molding represents a sophisticated manufacturing process that combines elements of both transfer molding and injection molding technologies. This hybrid approach offers unique advantages for producing complex, high-precision components across various industries. Unlike conventional injection molding, transfer pressure injection molding involves transferring material from a pot or chamber into a closed mold cavity under controlled pressure conditions.

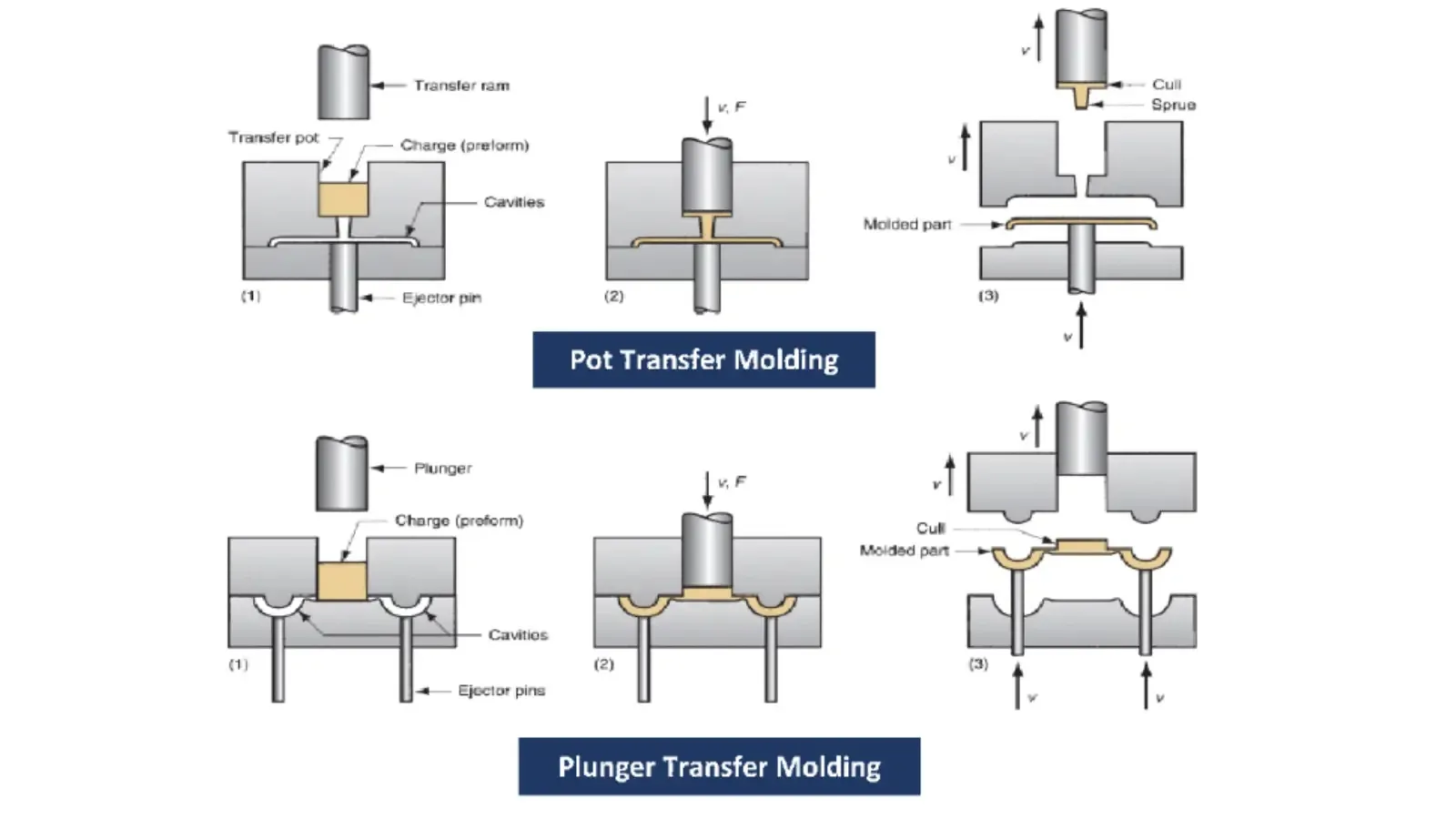

The process begins with pre-measured material placed in a transfer pot, which is then forced through runners and gates into the mold cavity using a plunger. This method provides superior control over material flow and pressure distribution, making it particularly suitable for encapsulating delicate components, producing parts with intricate geometries, and working with specialized materials that require precise processing conditions.

The Transfer Pressure Injection Molding Process

Stage 1: Material Preparation and Loading

The initial stage involves preparing the molding material, which can include thermosetting plastics, rubber compounds, or specialized polymers. The material is precisely measured and loaded into the transfer pot or chamber. For thermosetting materials, this stage is critical as the material must be at the optimal temperature and consistency for proper flow characteristics.

Stage 2: Mold Closing and Transfer

Once the mold is closed and securely clamped, the transfer mechanism activates. A plunger or ram applies controlled pressure to the material in the transfer pot, forcing it through the runner system and into the mold cavity. The pressure must be carefully regulated to ensure complete cavity filling without causing flash or damaging the mold components.

Stage 3: Curing and Solidification

During this phase, the material undergoes chemical cross-linking (for thermosets) or solidification (for thermoplastics) under maintained pressure. The curing time varies depending on the material properties, part thickness, and mold temperature. Maintaining pressure throughout this stage is crucial for preventing voids and ensuring dimensional stability.

Stage 4: Mold Opening and Part Ejection

After the prescribed curing time, the mold opens, and the finished part is ejected. The transfer pot typically contains residual material (cull) that must be removed before the next cycle. Modern systems often include automated cull removal and cleaning mechanisms to optimize cycle times.

Key Advantages of Transfer Pressure Injection Molding

Superior Part Quality and Consistency

Transfer pressure injection molding produces parts with excellent dimensional accuracy and surface finish. The controlled pressure application minimizes internal stresses and reduces the likelihood of warpage or sink marks. This results in components with consistent mechanical properties and reliable performance characteristics.

Enhanced Design Flexibility

This manufacturing method accommodates complex part geometries that would be challenging with conventional injection molding. The ability to encapsulate inserts and produce parts with varying wall thicknesses makes it ideal for electrical components, medical devices, and automotive applications.

Reduced Material Waste

The precise material measurement and controlled transfer process minimize material waste compared to other molding techniques. The runner system in transfer molding is typically simpler and more efficient, further contributing to material economy.

Applications Across Industries

Electronics and Electrical Components

Transfer pressure injection molding is extensively used for encapsulating electronic components such as connectors, sensors, and integrated circuits. The process provides excellent electrical insulation properties and protects delicate components from environmental factors.

Automotive Industry

Automotive applications include production of seals, gaskets, electrical connectors, and under-hood components. The method's ability to handle high-temperature materials and produce durable parts makes it valuable for demanding automotive environments.

Medical Device Manufacturing

Medical applications benefit from the process's precision and cleanliness. It is used for producing surgical instruments, device housings, and components requiring biocompatible materials with strict dimensional tolerances.

Comparison with Other Molding Techniques

| Parameter | Transfer Pressure Injection Molding | Conventional Injection Molding | Compression Molding |

|---|---|---|---|

| Material Versatility | Excellent for thermosets and filled materials | Primarily thermoplastics | Good for thermosets and rubber |

| Part Complexity | High - complex geometries and inserts | Moderate to High | Low to Moderate |

| Tooling Cost | Moderate to High | High | Low to Moderate |

| Production Rate | Moderate | High | Low to Moderate |

| Material Waste | Low | Moderate | Low |

Material Considerations and Selection

Thermosetting Materials

Epoxy, phenolic, and silicone compounds are commonly used in transfer pressure injection molding. These materials offer excellent thermal stability, chemical resistance, and mechanical properties suitable for high-performance applications.

Engineering Thermoplastics

While less common, certain engineering thermoplastics can be processed using transfer pressure techniques. These applications typically involve specialized requirements such as reduced internal stress or improved fiber orientation in reinforced materials.

Material Preparation Requirements

Proper material preparation is essential for successful transfer pressure injection molding. This includes precise pre-heating, moisture control, and compounding with additives or reinforcements as required by the specific application.

Process Optimization and Quality Control

Critical Process Parameters

Successful transfer pressure injection molding requires careful control of several key parameters:

- Transfer pressure and speed

- Mold temperature profile

- Material temperature and viscosity

- Cure time and temperature

- Plunger speed and pressure profile

Quality Assurance Measures

Implementing robust quality control systems is essential for maintaining part consistency. This includes regular monitoring of dimensional accuracy, mechanical properties, and visual inspection for defects such as flash, voids, or incomplete filling.

Future Trends and Developments

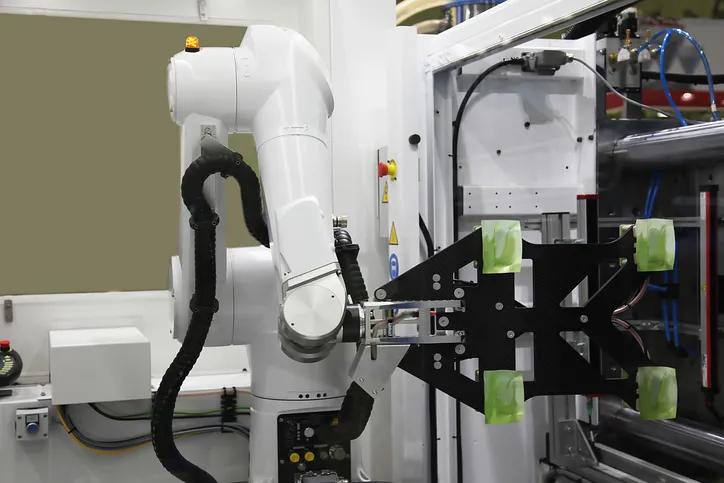

Automation and Industry 4.0 Integration

The integration of smart sensors, real-time monitoring systems, and data analytics is transforming transfer pressure injection molding operations. These technologies enable predictive maintenance, process optimization, and enhanced quality control through continuous monitoring of critical parameters.

Advanced Material Development

Ongoing research in material science is producing new compounds with improved properties, including enhanced thermal stability, better flow characteristics, and reduced environmental impact. Bio-based and recyclable materials are gaining attention for sustainable manufacturing applications.

Conclusion

Transfer pressure injection molding continues to be a vital manufacturing process for producing high-quality, precision components across multiple industries. Its unique combination of controlled material transfer and pressure application provides distinct advantages for applications requiring encapsulation of delicate components, complex geometries, and superior dimensional stability. As technology advances, this manufacturing method is evolving with improved automation, material options, and process control systems that enhance its capabilities and expand its application potential.

Understanding the principles, advantages, and limitations of transfer pressure injection molding enables manufacturers to select the most appropriate production method for their specific requirements while optimizing quality, efficiency, and cost-effectiveness.