Understanding the Different Types of Forging Presses

Forging is a fundamental manufacturing process that shapes metal using compressive forces. At the heart of this operation lies the forging press, a machine that applies controlled pressure to deform metal into desired shapes with superior strength and structural integrity. The choice of forging press significantly impacts the quality, efficiency, and economics of production. This article provides a detailed exploration of the primary types of forging presses, their mechanisms, and their industrial applications.

1. Mechanical Forging Presses

Mechanical forging presses utilize a motor-driven flywheel to store energy, which is then transferred through a clutch and a crankshaft or eccentric drive to a ram. This mechanism converts the rotary motion into a linear, reciprocating motion of the ram, delivering a forceful blow to the workpiece placed on the die.

Known for high operational speeds and repeatability, mechanical presses are ideal for high-volume production runs. They are commonly used for impression-die forging, coining, and precision forging of parts like automotive components and hand tools.

Key Characteristics of Mechanical Presses:

- Speed: Very high strokes per minute (SPM).

- Force Delivery: Delivers force at the bottom of the stroke; force is dependent on the press's design and capacity.

- Control: Less control over stroke length and speed during the operation compared to hydraulic presses.

- Efficiency: Highly efficient for mass production due to fast cycle times.

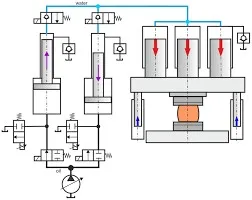

2. Hydraulic Forging Presses

Hydraulic forging presses generate force using pressurized hydraulic fluid. A hydraulic pump drives fluid into cylinders, which then move the ram. This design allows for full control over the ram's speed, position, and pressure throughout the entire stroke.

The defining advantage of hydraulic presses is their flexibility. They can deliver a constant force across the full stroke length, making them perfect for forging large, complex parts and materials that require slow, controlled deformation, such as aerospace components, turbine blades, and heavy structural parts.

| Feature | Mechanical Press | Hydraulic Press |

|---|---|---|

| Force & Stroke Control | Fixed stroke; force peaks at bottom dead center. | Full control over stroke length and constant force throughout. |

| Speed | Very High | Slower, but controllable |

| Versatility | Best for high-volume, simpler shapes | Excellent for large, complex, and low-volume parts |

| Energy Consumption | High during operation, lower in standby | Consumes energy mainly during ram movement |

3. Screw Presses

Screw presses represent a hybrid category, using a large flywheel driven by an electric motor. The energy from the rotating flywheel is transferred to a vertical screw mechanism, which converts rotational energy into linear motion of the ram.

They deliver energy-limited blows, meaning the deformation force depends on the stored kinetic energy in the flywheel. This makes them exceptionally good for precision forgings and materials sensitive to high strain rates, like titanium and superalloys. The process is often characterized by a series of rapid, successive blows.

4. Forging Hammers (Drop Hammers)

While not always classified as "presses" in the strictest sense, forging hammers are a traditional and vital forging machine. They apply force through the impact of a falling weight or ram. The energy is delivered in a single, high-velocity blow, which is excellent for drawing out material and open-die forging.

Hammers are categorized into gravity drop hammers (powered by the ram's weight) and power hammers (using air, steam, or hydraulics to accelerate the ram). They are versatile for both open-die and impression-die forging but are generally noisier and create more vibration than presses.

Selecting the Right Forging Press

The selection of a forging press depends on multiple interrelated factors:

Key Selection Criteria:

- Part Specifications: Size, complexity, material (e.g., aluminum, steel, exotic alloys), and required precision.

- Production Volume: High-volume runs favor mechanical presses, while low-volume, large parts suit hydraulic presses.

- Deformation Requirements: Processes needing constant force (extrusion) need hydraulic presses, while simple stamping suits mechanical ones.

- Capital and Operational Costs: Initial investment, maintenance, and energy consumption vary significantly between types.

Understanding the fundamental differences between mechanical, hydraulic, screw, and hammer-type forging equipment is crucial for optimizing manufacturing processes. Each type offers a unique combination of force, speed, control, and cost, making it suitable for specific applications within the vast landscape of metal forming.