What is a Stamping Press - Complete Guide

A stamping press is a vital piece of industrial equipment used in manufacturing to shape and cut metal sheets into specific forms through a process called stamping. These powerful machines apply tremendous force to deform and shape metal materials using dies and tooling, making them essential in numerous industries from automotive to electronics.

Fundamental Working Principles of Stamping Presses

Stamping presses operate on relatively simple mechanical principles but with sophisticated execution. The core function involves placing a flat metal sheet or coil between two halves of a die, then applying extreme pressure to either cut, bend, or form the material into the desired shape.

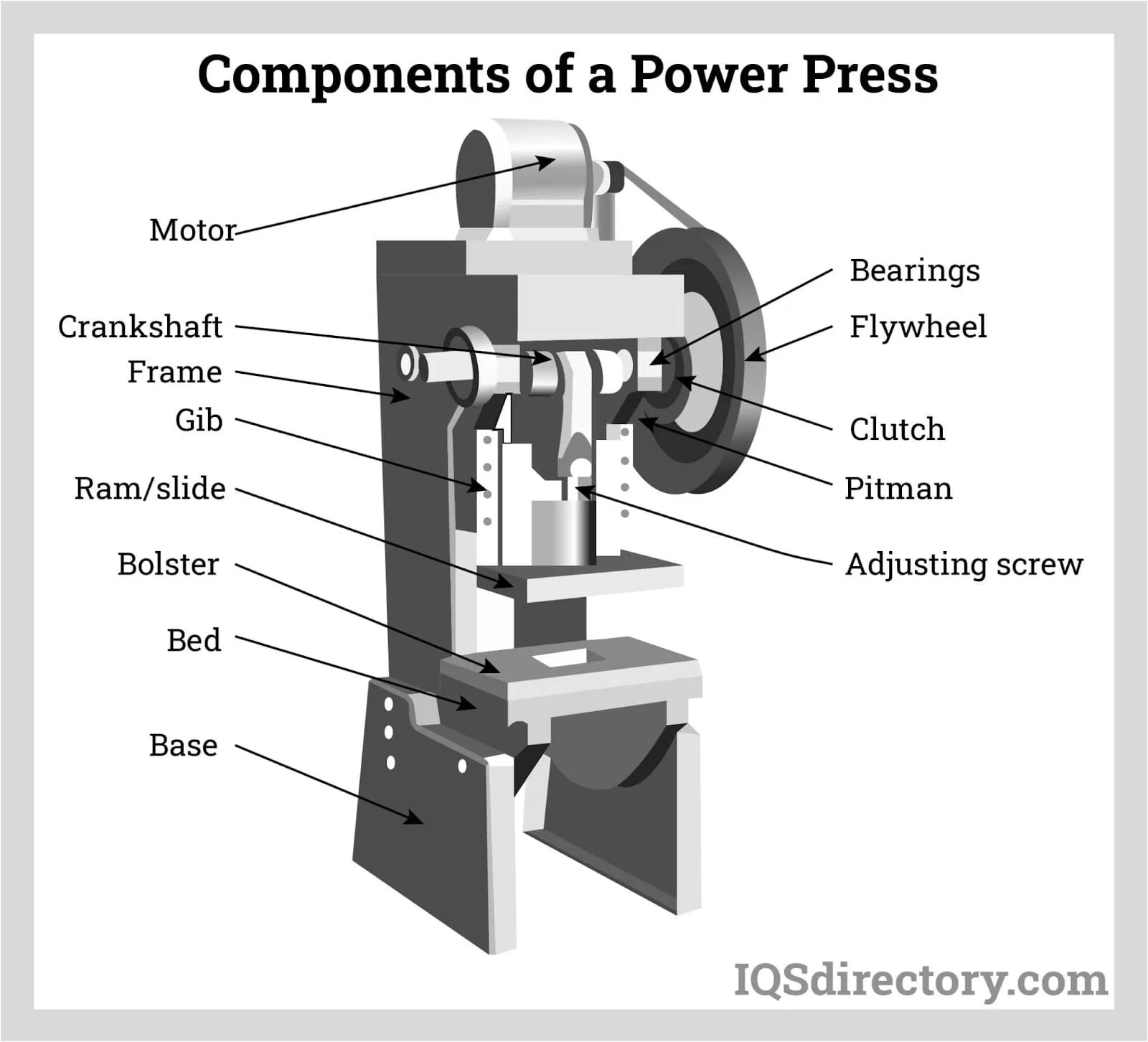

Key Mechanical Components

Every stamping press consists of several critical components that work in harmony:

- Frame: The structural foundation that supports all other components

- Bolster Plate: The platform where dies are mounted

- Ram/Slide: The moving component that applies downward force

- Drive System: The mechanism that powers the ram movement

- Clutch and Brake: Safety and control systems

Types of Stamping Presses

Stamping presses are categorized based on their power source and mechanical design, each offering distinct advantages for specific applications.

Mechanical Stamping Presses

Mechanical presses use a motor connected to a flywheel that stores rotational energy. This energy is transferred through gears and a crankshaft to create the linear motion of the ram. They're known for high speed and consistent performance.

Hydraulic Stamping Presses

Hydraulic presses use fluid pressure to generate force. They offer greater control over force and stroke length, making them ideal for deep drawing operations and applications requiring variable pressure.

Servo-Driven Stamping Presses

The most modern type, servo presses use programmable servo motors for precise control over every aspect of the stamping process, offering unparalleled flexibility and energy efficiency.

Stamping Press Specifications and Capabilities

| Press Type | Force Capacity Range | Speed (SPM) | Primary Applications | Advantages |

|---|---|---|---|---|

| Mechanical | 5 - 5,000 tons | 20 - 1,500 | High-volume production, blanking | High speed, consistent performance |

| Hydraulic | 10 - 10,000+ tons | 5 - 400 | Deep drawing, variable force applications | Full force throughout stroke, customizable |

| Servo | 30 - 4,000 tons | 10 - 800 | Precision stamping, prototyping | Energy efficient, programmable motion |

Stamping Operations and Processes

Stamping presses perform various metal forming operations, each serving different manufacturing needs.

Blanking and Piercing

Blanking involves cutting a piece of sheet metal to create a flat shape, while piercing creates holes or cutouts in the material. Both operations use shearing force to separate metal.

Bending and Forming

Bending operations create angled shapes in metal sheets, while forming encompasses various processes that shape metal without cutting it, including deep drawing, embossing, and coining.

Deep Drawing

This specialized process forms sheet metal into three-dimensional shapes with significant depth, commonly used for creating containers, automotive panels, and kitchen sinks.

Applications Across Industries

Stamping presses serve as foundational equipment in numerous manufacturing sectors, producing components we encounter daily.

Automotive Industry

The automotive sector is the largest user of stamping presses, producing body panels, chassis components, brackets, and numerous other parts that make up modern vehicles.

Aerospace and Defense

Precision stamping creates critical components for aircraft, satellites, and defense systems, where exact tolerances and material integrity are paramount.

Electronics and Appliances

From smartphone chassis to refrigerator panels, stamping presses form the metal components that house our electronic devices and household appliances.

Safety Considerations and Modern Innovations

Modern stamping presses incorporate numerous safety features and technological advancements that have transformed their operation and capabilities.

Safety Systems

Contemporary presses include light curtains, two-hand controls, emergency stops, and interlocked guards to protect operators from the significant hazards associated with these powerful machines.

Automation Integration

Modern stamping operations increasingly incorporate robotics for material handling, quick die change systems, and sophisticated monitoring software to optimize production efficiency.

Selecting the Right Stamping Press

Choosing the appropriate stamping press involves considering multiple factors to match the machine's capabilities with production requirements.

| Consideration Factor | Key Questions | Impact on Selection |

|---|---|---|

| Production Volume | High-volume mass production or low-volume custom work? | Determines speed requirements and automation needs |

| Material Type | What metals and thicknesses will be processed? | Affects required tonnage and press type |

| Part Complexity | Simple blanks or complex multi-stage formed parts? | Influences press sophistication and tooling requirements |

| Budget Constraints | Initial investment vs. long-term operational costs? | Balances purchase price with efficiency and maintenance costs |

Future Trends in Stamping Press Technology

The evolution of stamping presses continues with several emerging trends shaping their future development and application.

Smart Manufacturing Integration

Industry 4.0 technologies are transforming stamping presses into connected devices that provide real-time data for predictive maintenance, quality control, and production optimization.

Energy Efficiency Focus

Newer press designs prioritize reduced energy consumption through regenerative drives, improved motor technology, and smarter control systems that minimize power usage during idle periods.

Hybrid Press Technologies

Combining the benefits of mechanical and hydraulic systems, hybrid presses offer the speed of mechanical operation with the flexibility and control of hydraulic systems.

Stamping presses remain indispensable in modern manufacturing, continuously evolving to meet the demands for higher precision, greater efficiency, and increased flexibility in metal forming operations across countless industries.